Method and Device For Checking the Function For Inverting the Polarity on a Subscriber Line Comprising a Plurality of Wires

a subscriber line and function technology, applied in the direction of substation equipment, electrical apparatus, supervision/monitoring/testing arrangements, etc., can solve the problems of needing to operate appropriately by additional personnel and external measuring equipment described above, so as to avoid additional personnel and financial involvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

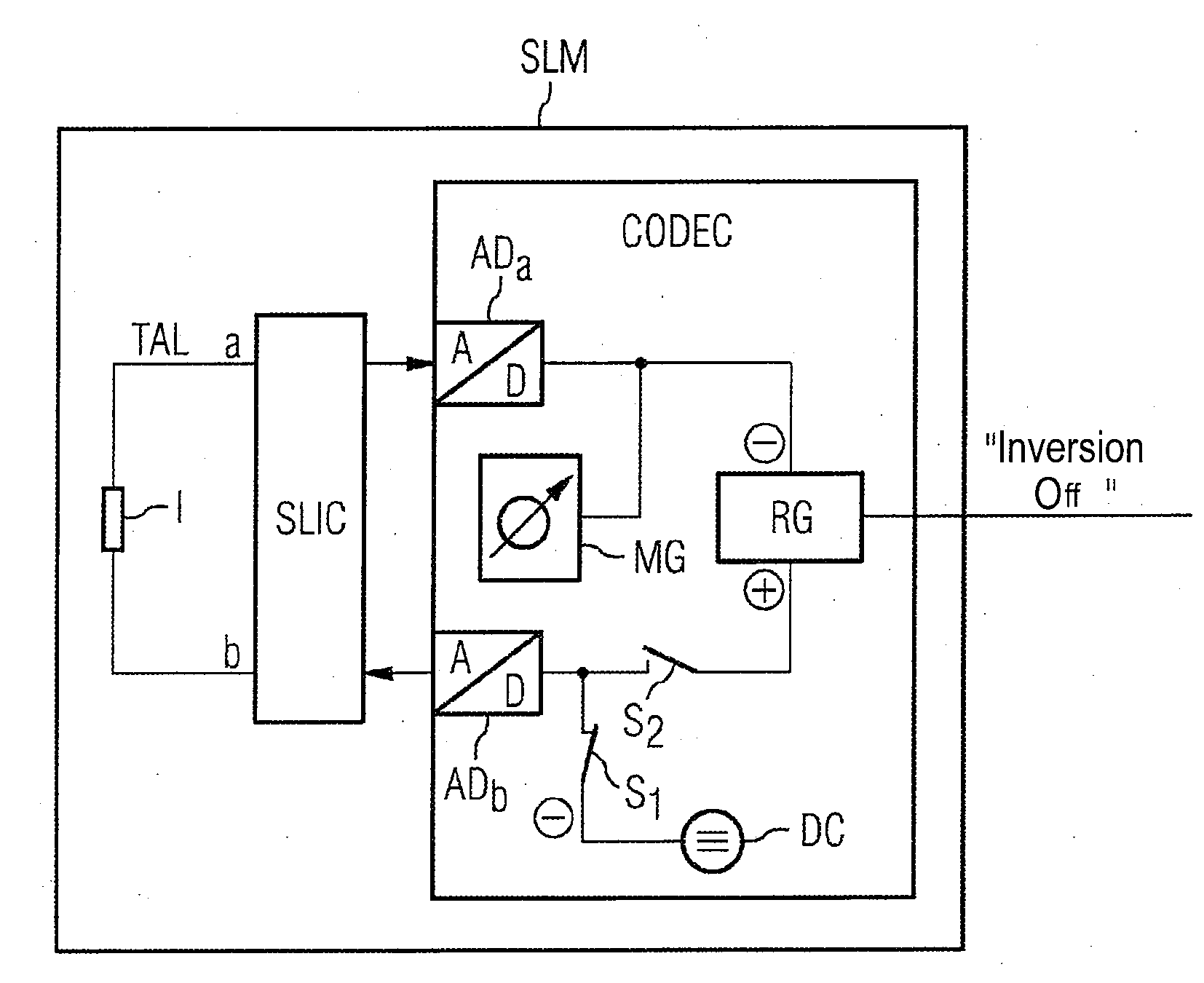

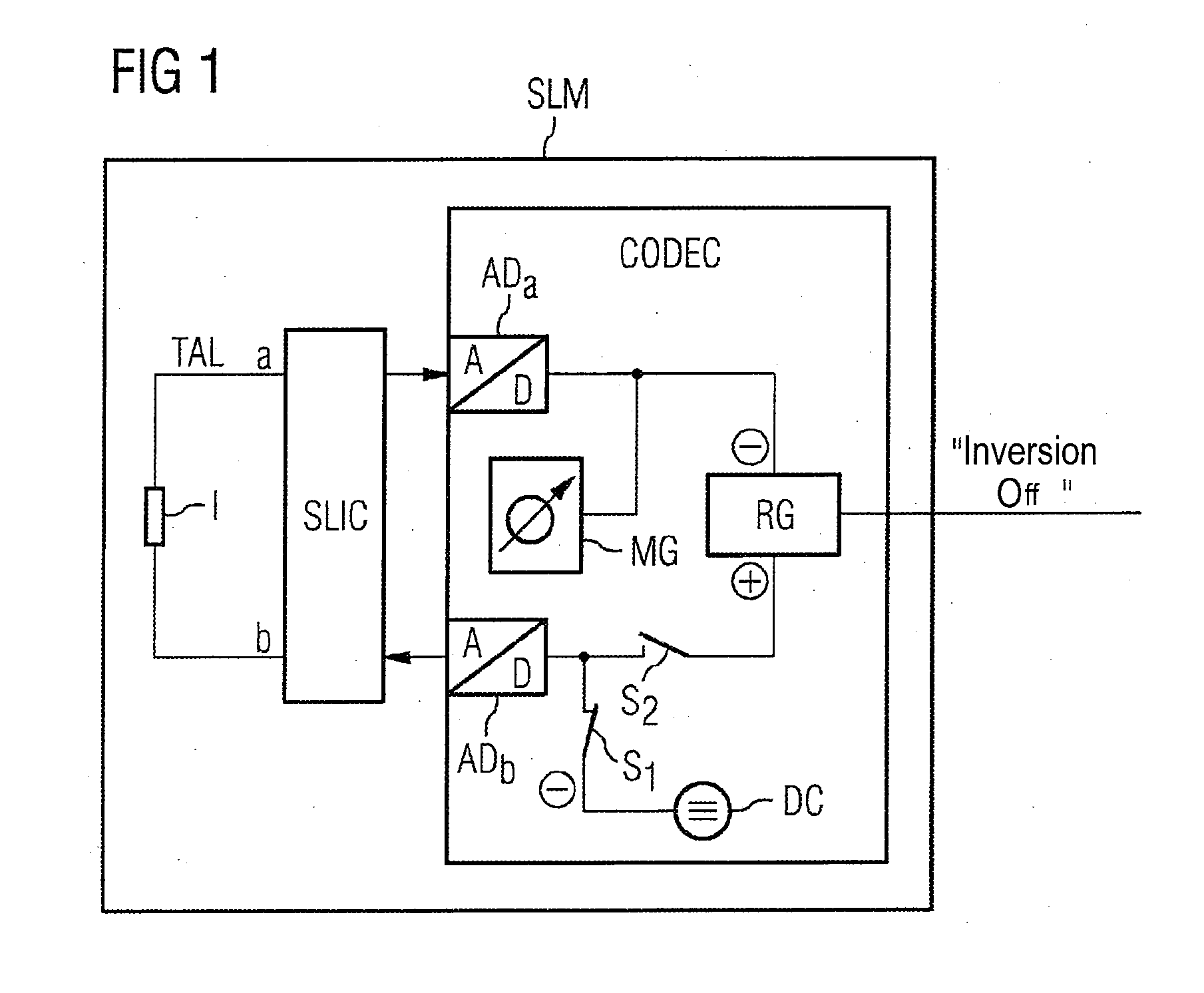

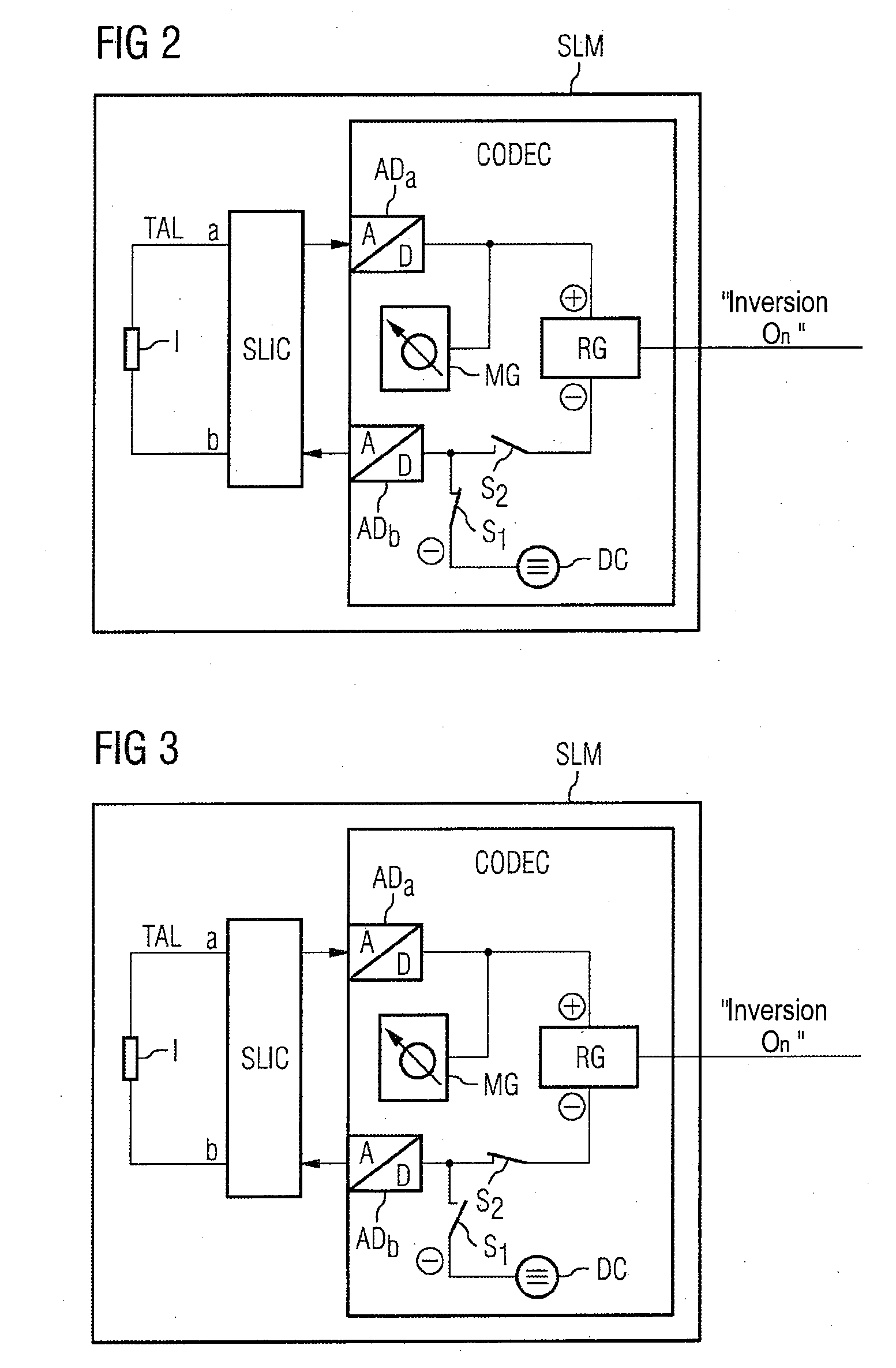

[0021]The text below describes the schematic design of a subscriber line module in a conventional communication network for performing the invention with reference to FIGS. 1, 2 and 3.

[0022]In this example, a test impedance I has been connected between two wires a and b of a subscriber line TAL at the exchange end (not shown). When this test impedance I is switched in, the subscriber is simultaneously isolated from the exchange, which prevents any disruption to the subscriber during the check.

[0023]The subscriber line TAL is connected to a subscriber line interface circuit SLIC, which in turn represents the interface to an encoder / decoder CODEC at the exchange (not shown).

[0024]The CODEC comprises a respective analog / digital converter ADa, ADb for each of the wires a, b of the subscriber line TAL and an inversion device (“reversal generator”—RG), a direct current source (“DC generator”—DC) and a measuring instrument MG.

[0025]The inversion device RG can be switched to a plurality of

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap