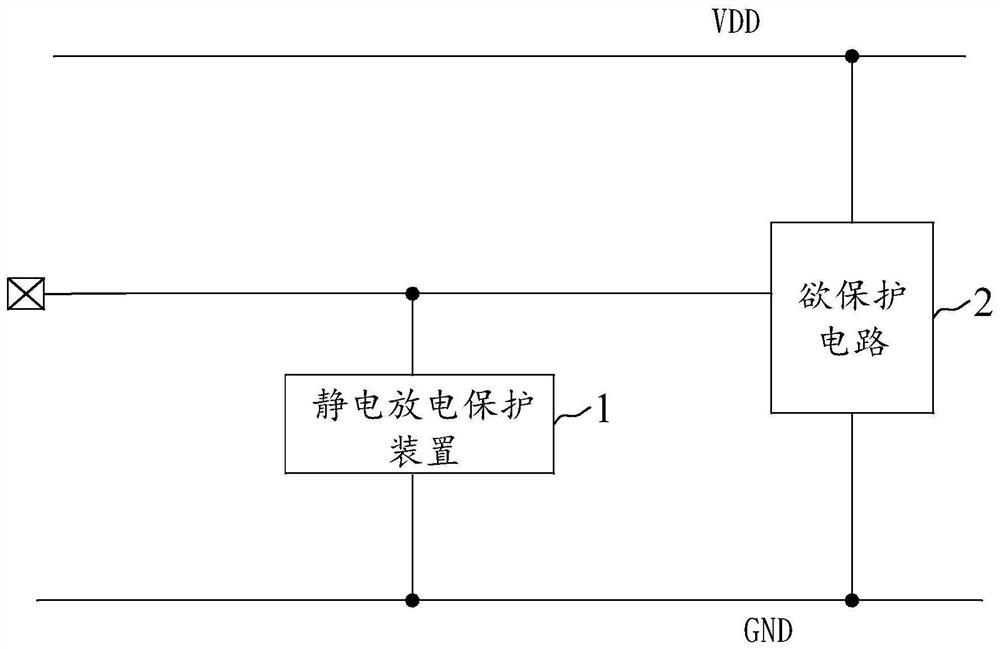

Bidirectional electrostatic discharge protection device

An electrostatic discharge protection, bipolar technology, applied in the field of bidirectional electrostatic discharge protection devices, can solve the problems of increasing the complexity of the process, and achieve the effect of reducing the complexity of the process and increasing the level of electrostatic discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

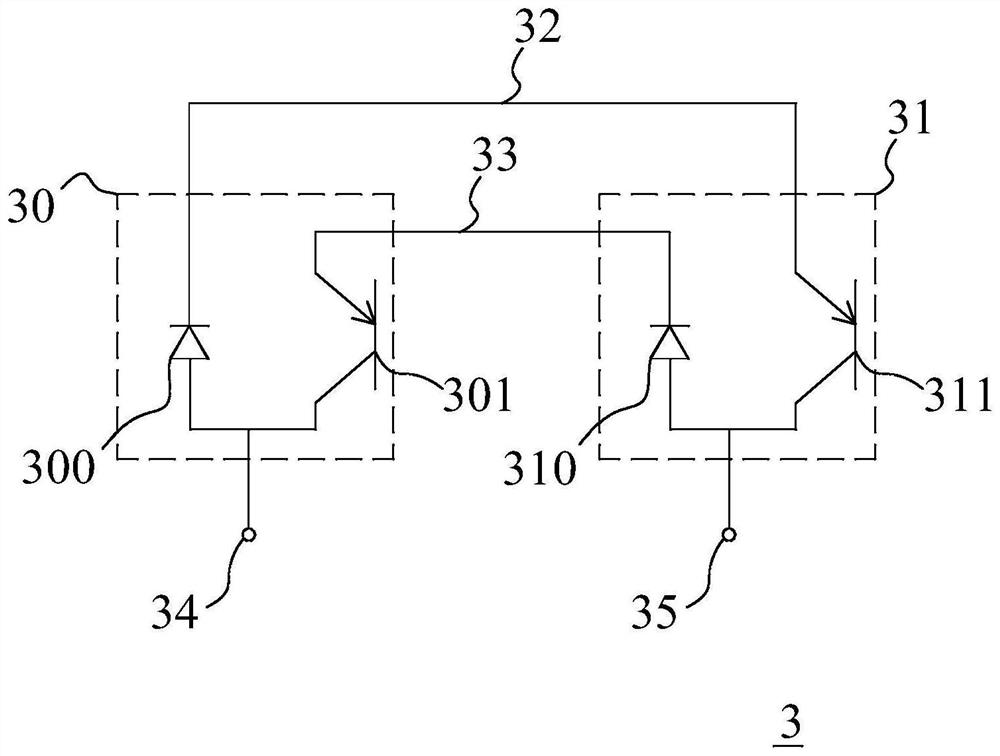

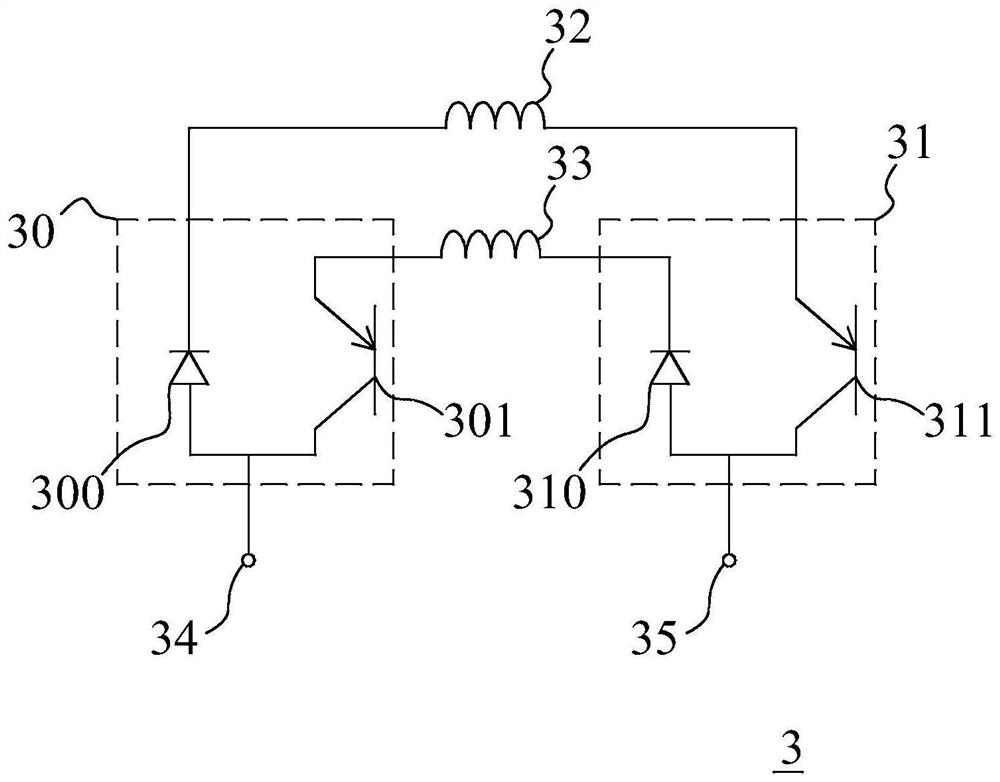

Embodiment Construction

[0035] The embodiments of the present invention will be further explained below with the relevant drawings. Wherever possible, in the drawings and the description, the same reference numbers refer to the same or similar components. In the drawings, shapes and thicknesses may be exaggerated for simplicity and convenience. It should be understood that elements that are not particularly shown in the drawings or described in the specification have forms known to those of ordinary skill in the art. Those skilled in the art can make various changes and modifications based on the content of the present invention.

[0036] Unless otherwise specified, some conditional sentences or words, such as "can", "could", "might", or "may", are usually intended to express that the embodiments of this case have, However, it can also be interpreted as features, elements or steps that may not be required. In other embodiments, these features, elements or steps may not be required.

[0037] The foll

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap