X-Ray CT Apparatus

a technology of ct apparatus and x-ray, which is applied in the direction of material analysis, tomography, instruments, etc., can solve the problem of a smaller number of development proposals of industrial x-ray ct apparatus, and achieve the effect of easy change of resolution (that is, the imaging area)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]An embodiment of the present invention will be described hereunder in detail with reference to the drawings.

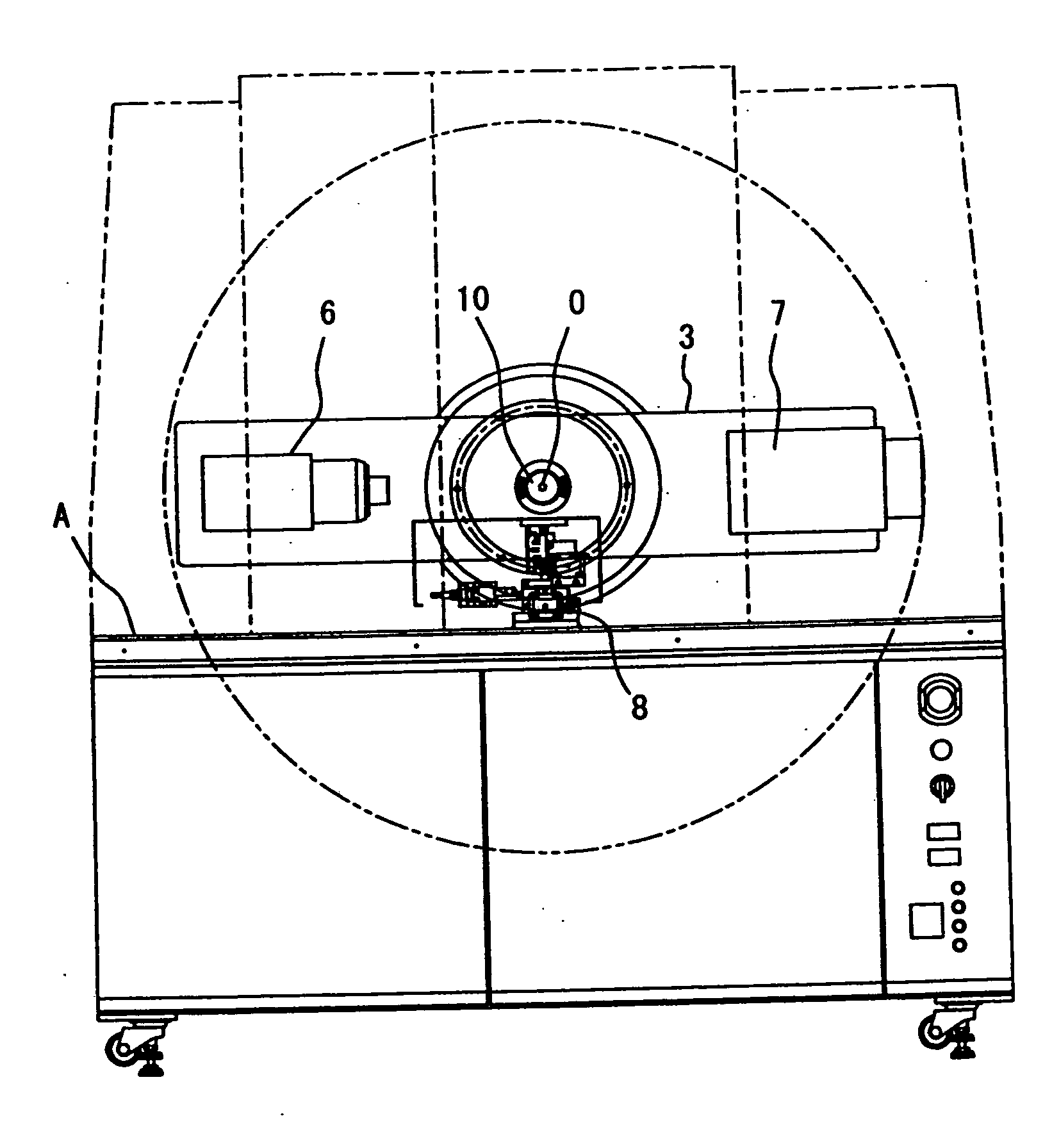

[0044]FIG. 3 is a front view showing an X-ray CT apparatus according to an embodiment of the present invention, and FIG. 4 is a side perspective view showing the X-ray CT apparatus. First, the overall construction of the X-ray CT apparatus according to the embodiment will be described with reference to these drawings.

[0045]As shown in FIG. 4, a bearing stand 1 is mounted at a position near to the rear portion of the top surface of a table A of the main body of the X-ray CT apparatus. The bearing stand 1 is provided with a cylindrical bearing 2, and the center portion of a guide arm 3 (rotational support member) is freely rotatably mounted to the bearing 2. Here, the center axis of the bearing 2 corresponds to a rotational axis O of the guide arm 3, and the rotational axis O extends in the horizontal direction. A sample S is disposed on the rotational axis O (horizontal axis

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap