Master cylinder

a master cylinder and cylinder body technology, applied in the direction of rotary clutches, braking systems, fluid couplings, etc., can solve the problems of inability to immediately open the relief port and release the residual pressure, and achieve the effect of further ensuring the response during brake actuation and improving the release delay during brake releas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]An embodiment of the application of the present invention will be described below with reference to the drawings.

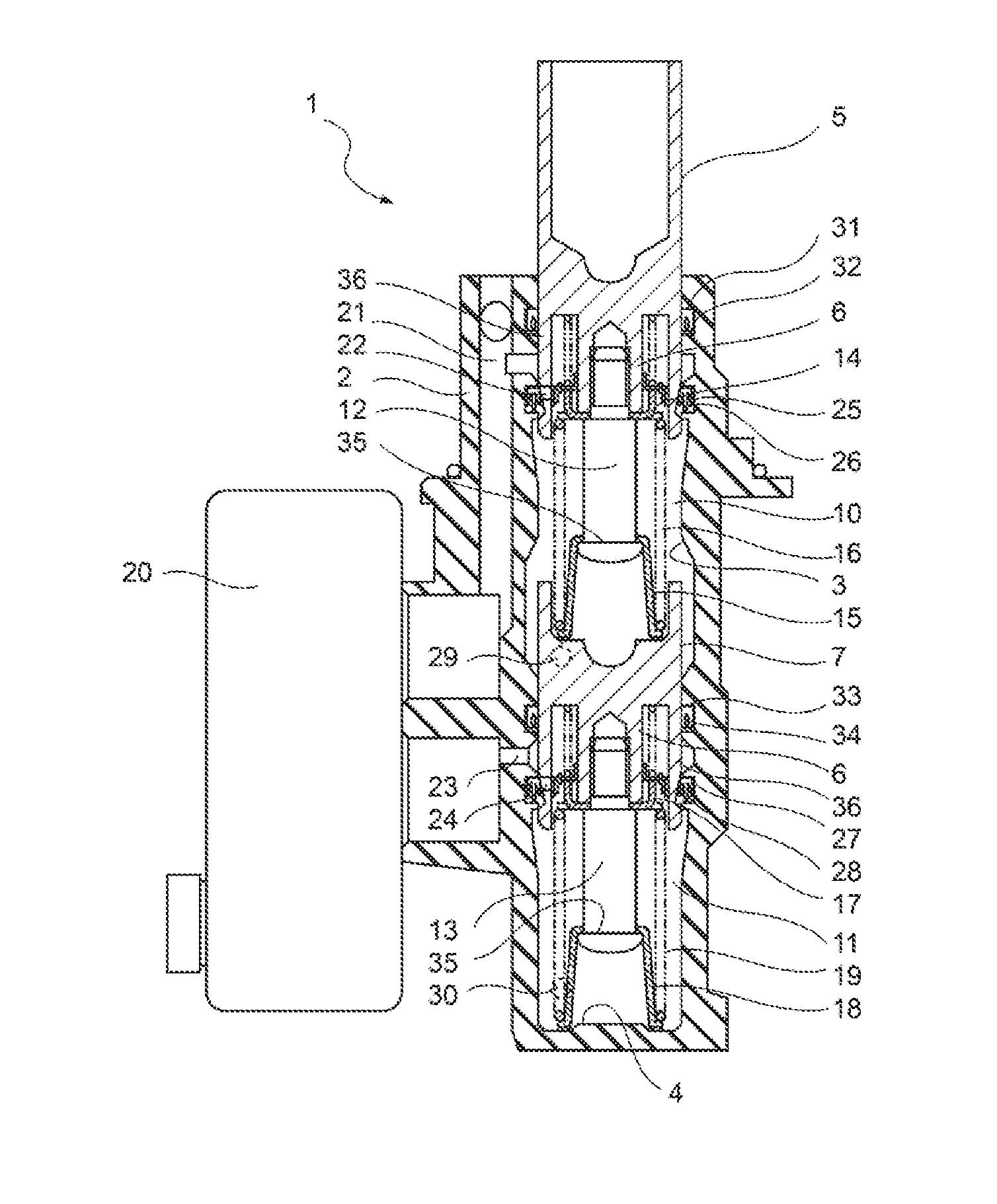

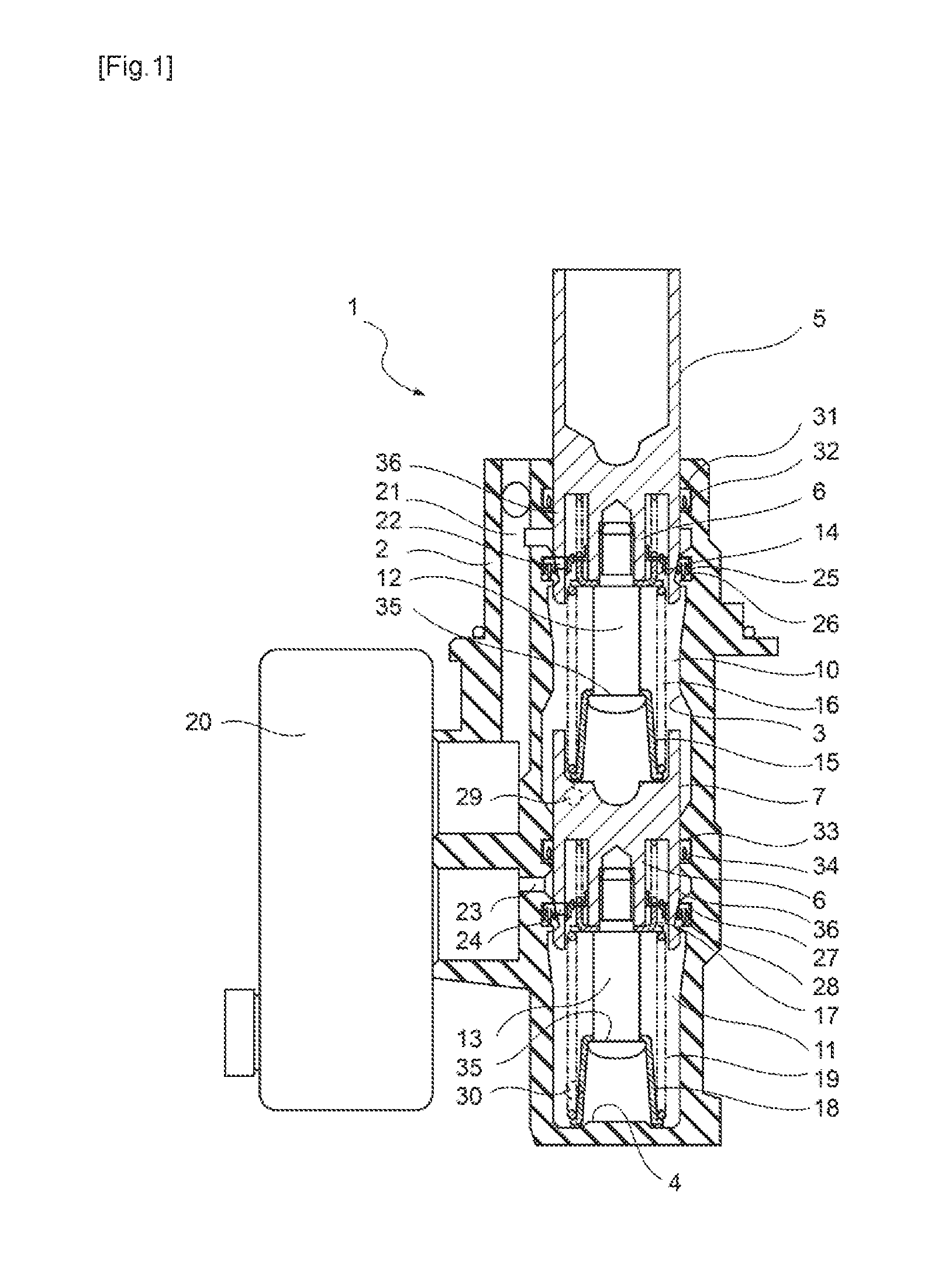

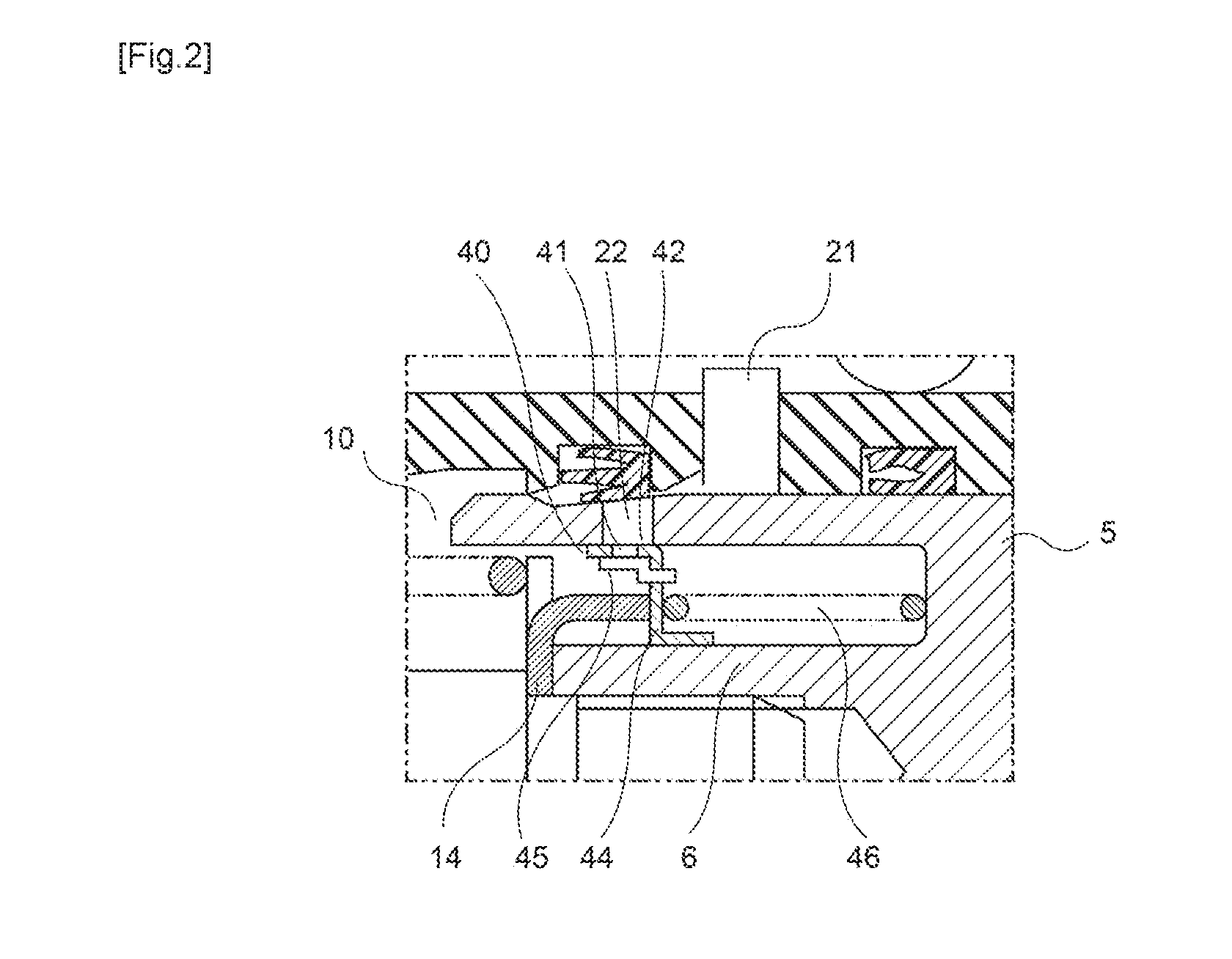

[0023]FIG. 1 illustrates an entire master cylinder according to an embodiment of the present invention. As illustrated in FIG. 1, a plunger type master cylinder 1 has a cylinder body 2 and a cylinder hole 3 is formed in the cylinder body 2.

[0024]A primary piston 5, which is an example of pistons according to the invention, and a secondary piston 7, which is also an example of pistons according to the invention, are slidably inserted into the cylinder hole 3. The primary piston 5 is moved to the left by a brake pedal (not illustrated) or a brake booster boosting and outputting the depressing force of the brake pedal. The primary piston 5 and the secondary piston 7 partition and form a first hydraulic chamber 10 between the primary piston 5 and the secondary piston 7 and partition and form a second hydraulic chamber 11 between the secondary piston 7 and a bottom 4 of the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap