Conformal coating materials

a technology of coating materials and coating materials, applied in the direction of non-metallic protective coating applications, circuit masks, laminating printed circuit boards, etc., can solve the problems of component failure, corrosion of metallurgy, and failure to test the hardware's suitability for harsh indoor air environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

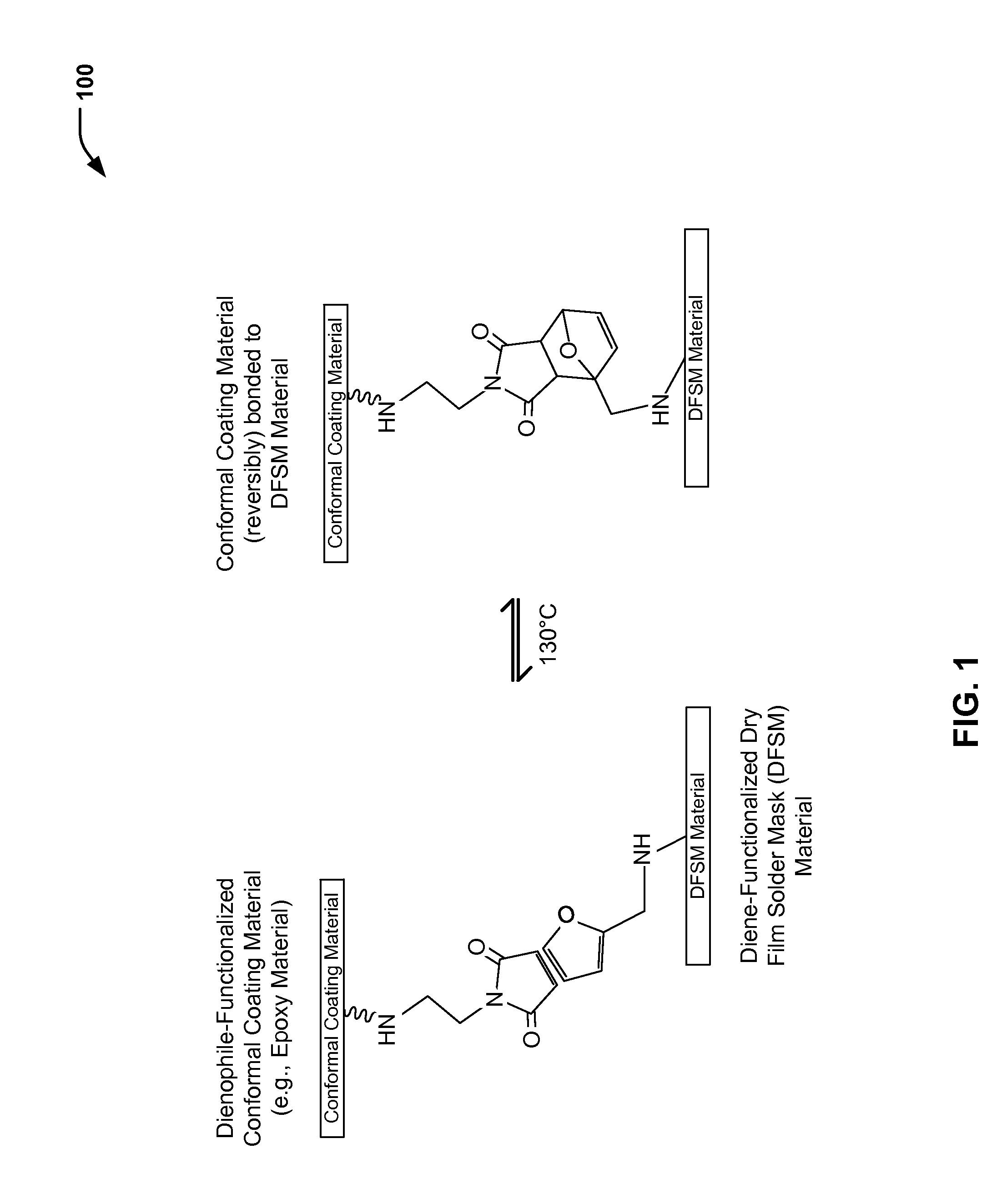

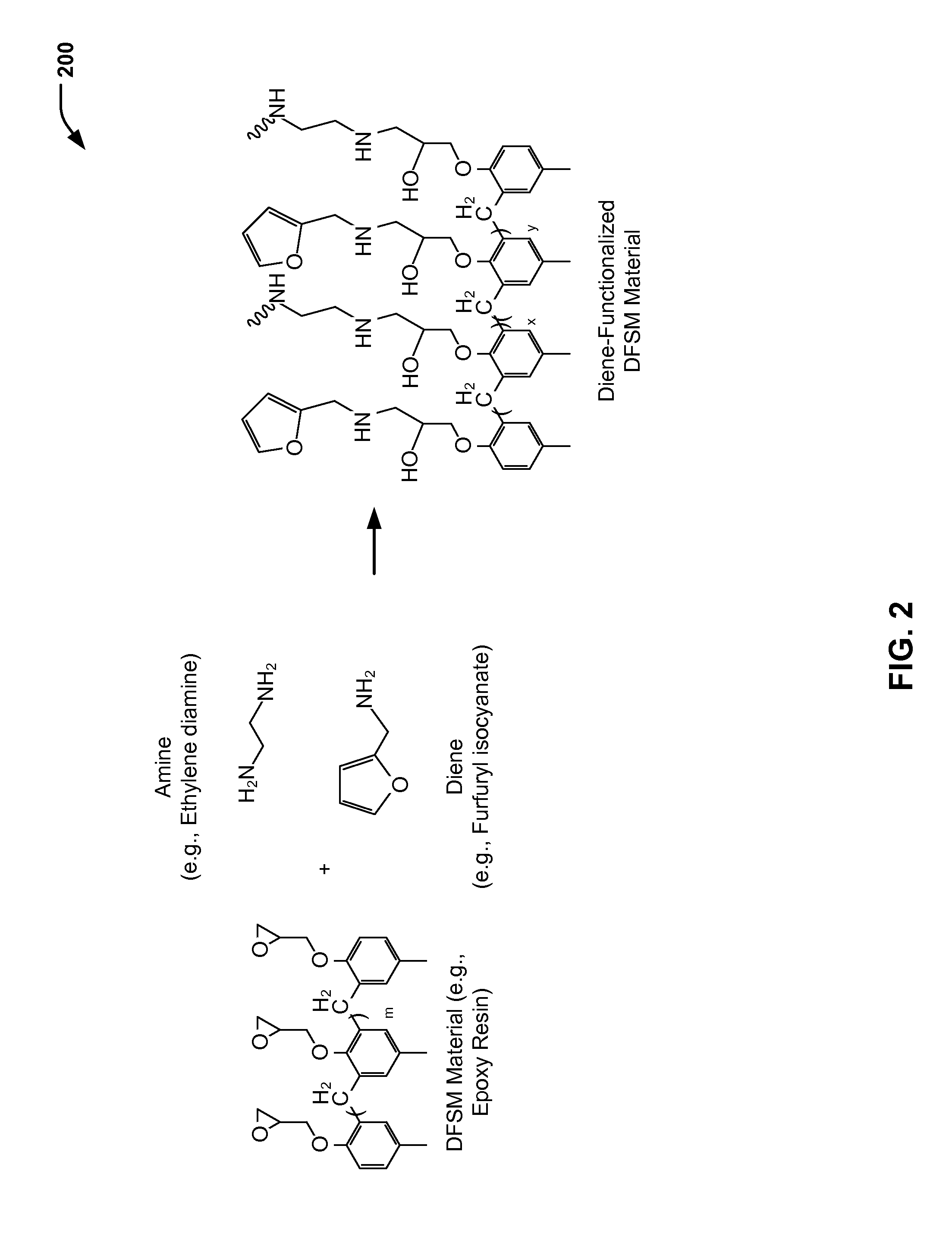

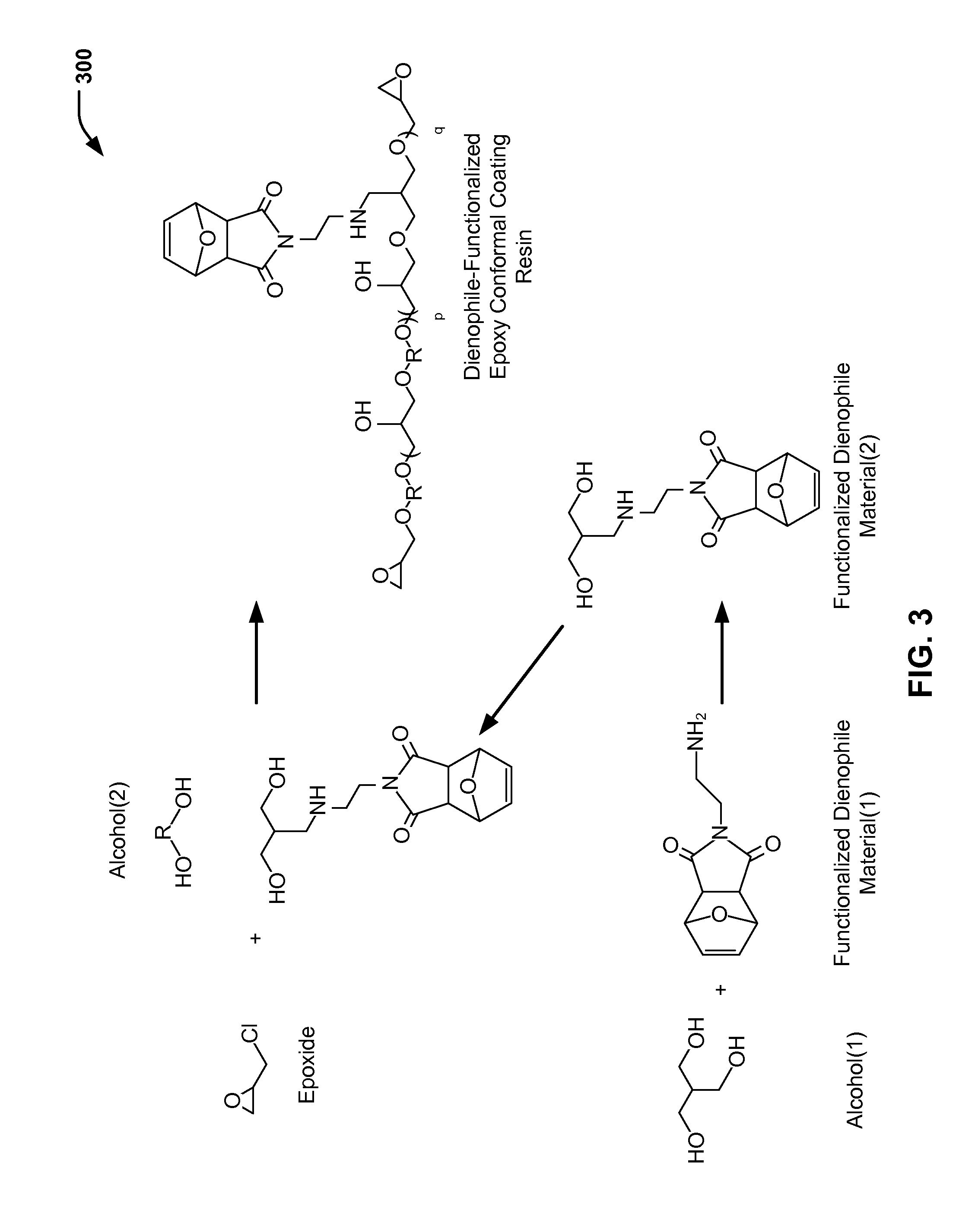

[0014]The present disclosure relates to functionalized conformal coating materials and methods of reversibly bonding the functionalized conformal coating materials to a functionalized dry film solder mask (DFSM) material. In the present disclosure, a conformal coating material that includes a first functional group (e.g., a dienophile functional group) may be reversibly bonded to a DFSM material via a chemical reaction of the first functional group with a second functional group (e.g., a diene functional group) of the DFSM material. The present disclosure describes illustrative examples of functionalization of conformal coating materials to include dienophile functional groups and functionalization of DFSM materials to include diene functional groups. One of ordinary skill in the art will appreciate that, in other cases, the conformal coatings may be functionalized to include diene functional groups, and the DFSM materials may be functionalized to include dienophile functional groups.

[

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap