Resistive charcoal igniter system and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

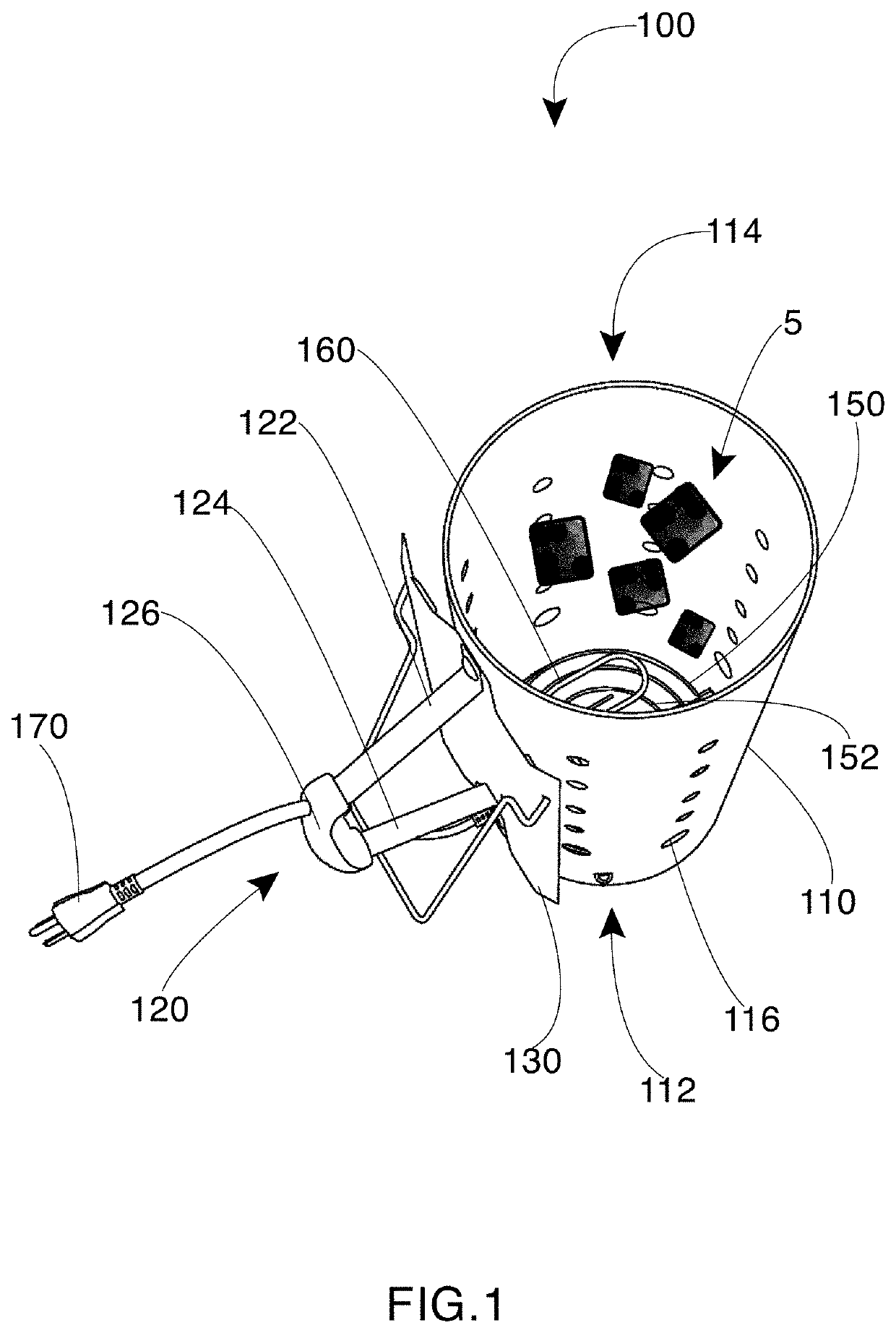

[0015]As discussed above, embodiments of the present disclosure relate to a fuel lighter and more particularly to a resistive charcoal igniter system and method as used to improve the lighting of charcoal, lump charcoal, or charcoal briquets for a barbecue.

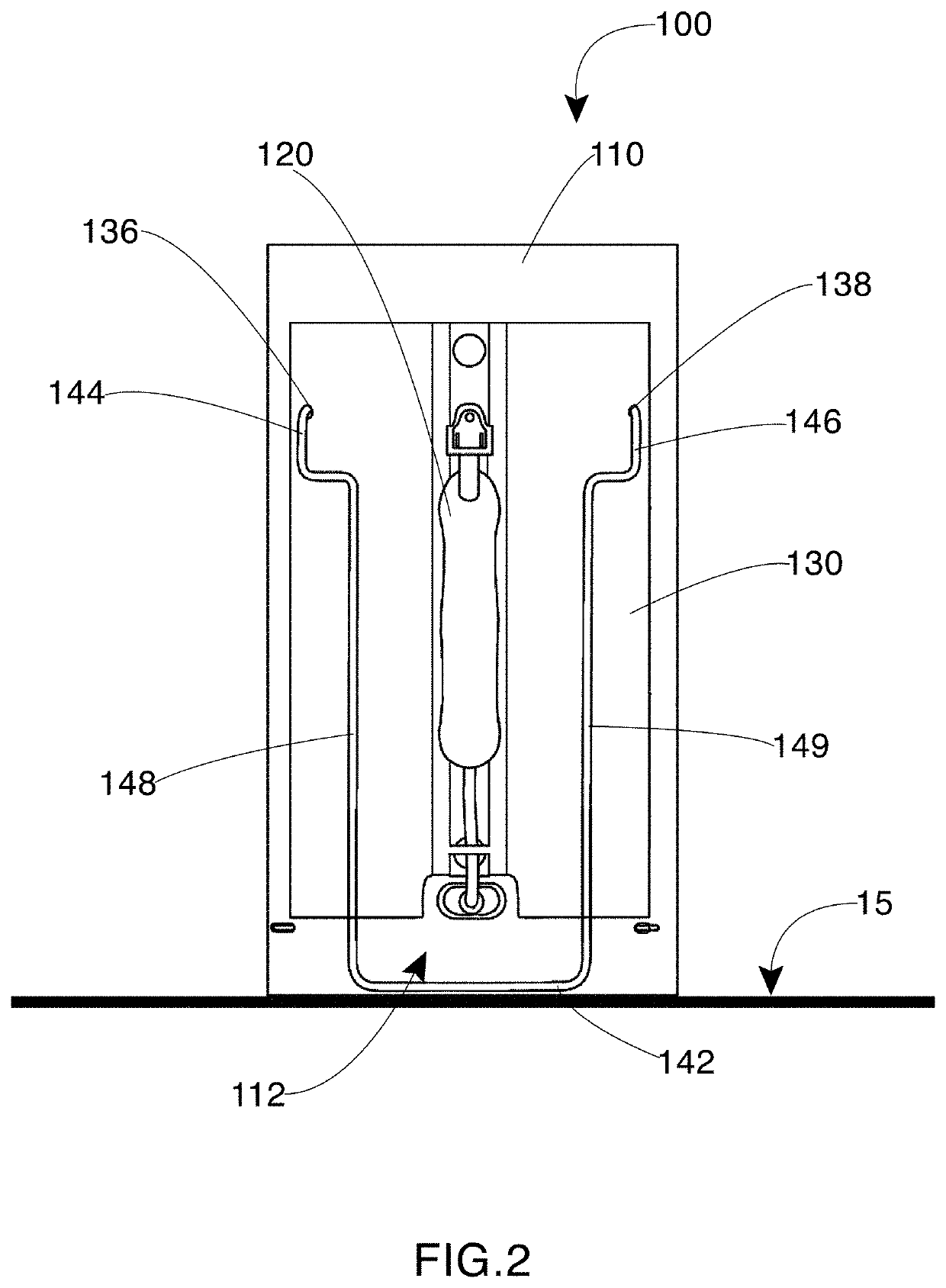

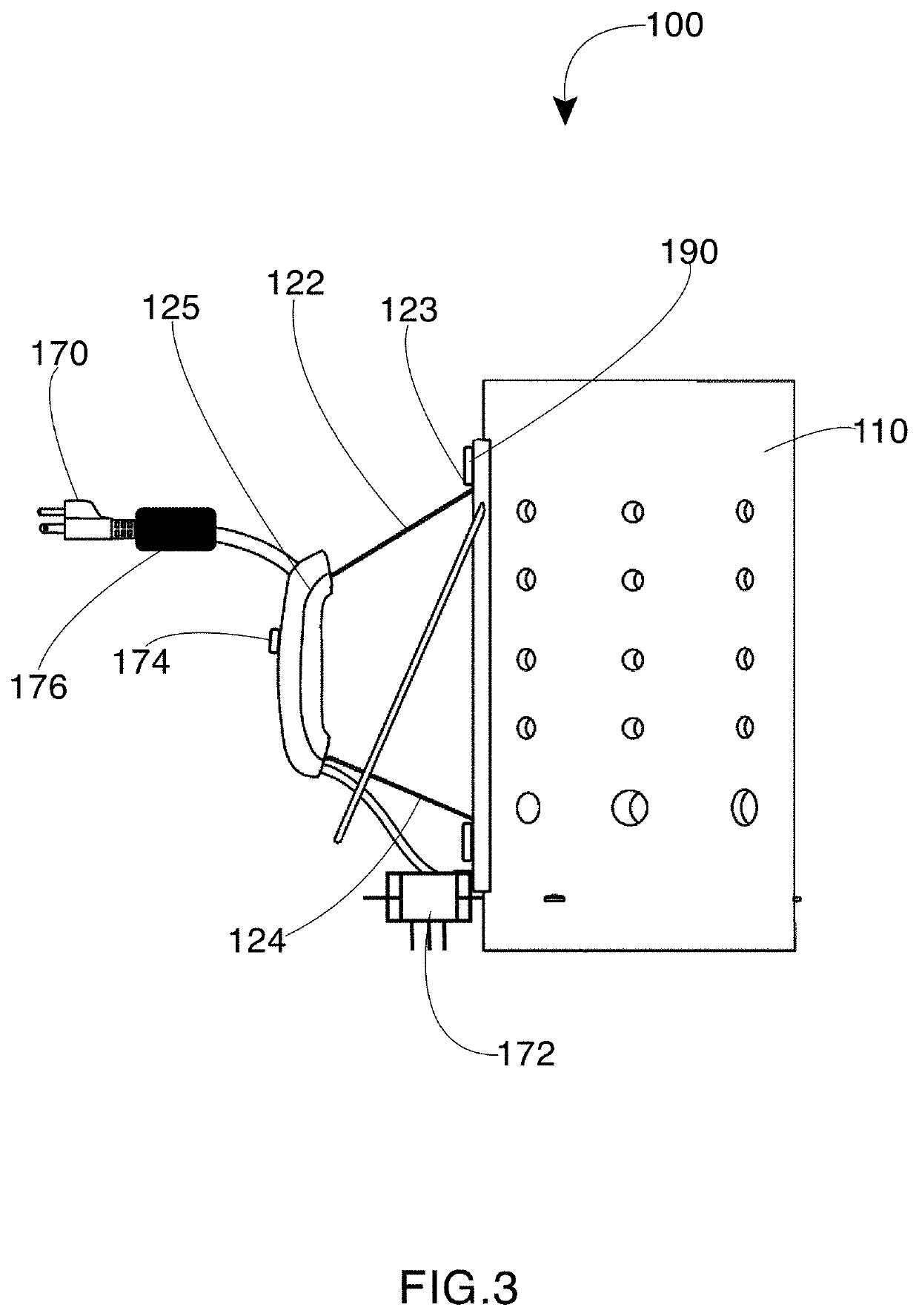

[0016]The resistive charcoal igniter system includes a device for containing and igniting charcoal, lump charcoal, or charcoal briquets. The device includes a cylindrical container with a wire base in the bottom for containing the charcoal. The cylinder may be constructed of galvanized sheet steel and have apertures providing ventilation and airflow.

[0017]An electrically operated heating element is located within the wire base. When charcoal is placed in the container, and the heating element is energized, the charcoal, lump charcoal, or charcoal briquets ignite after enough time. The device also includes a handle affixed to the container and a heatshield placed between the handle and the container to protect a user's hand from heat

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap