Anti-contamination needle removing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

[0026]It is to be noted that, unless otherwise specified, the technical and scientific terms used herein refer to common meanings generally understood by a person skilled in the art. Furthermore, the term “a” used in the description refers to a quantity of at least one (one or more) unless otherwise specified. It should also be noted that, the descriptive terms related to orientation (e.g., “front”, “back”, “upper”, and “lower”, etc.) used in the description are illustrative or relative terms which need to be conceptively adjusted according to different users or different usages, and are not enumerative or absolute terms.

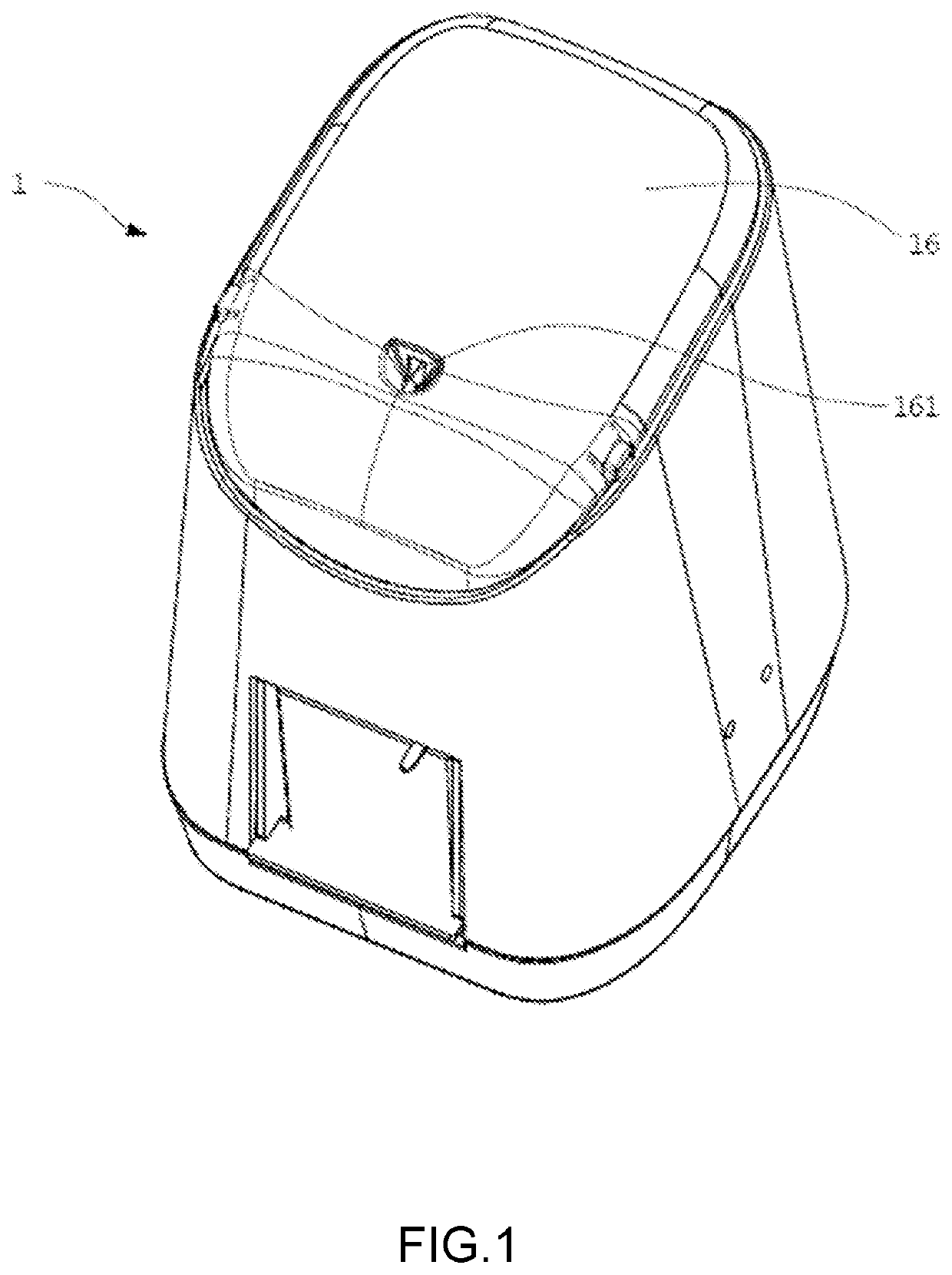

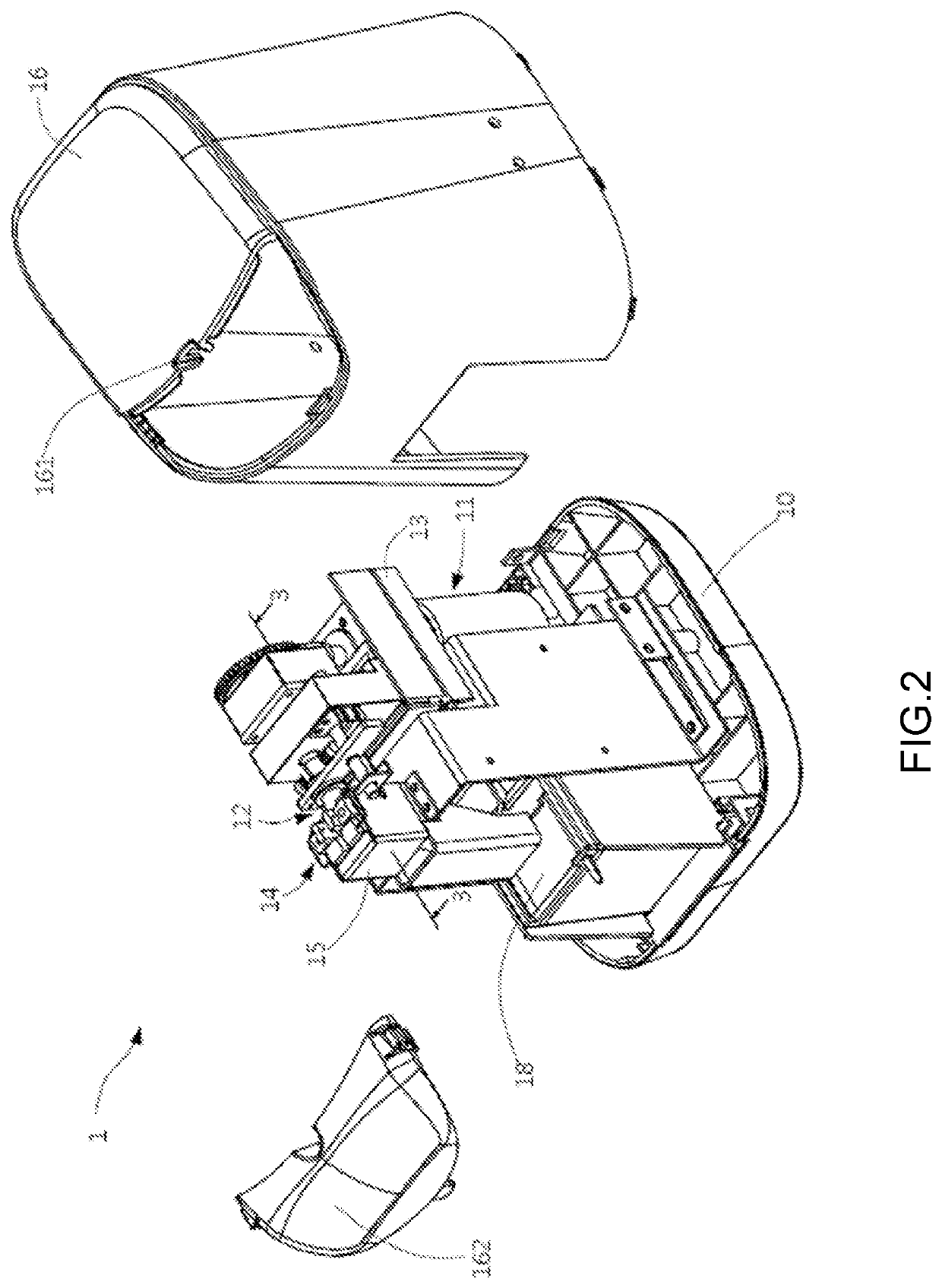

[0027]Referring to FIG. 1 and FIG. 2, FIG. 1 shows a perspective schematic diagram of a needle removing device 1 according to an embodiment of the present invention, and FIG. 2 shows an exploded schematic diagram of partial components of the needle removing device 1 according to an embodiment of the present invention. In this embodiment, the needle removing device 1 is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap