Heating coil, heating apparatus and manufacturing method of workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

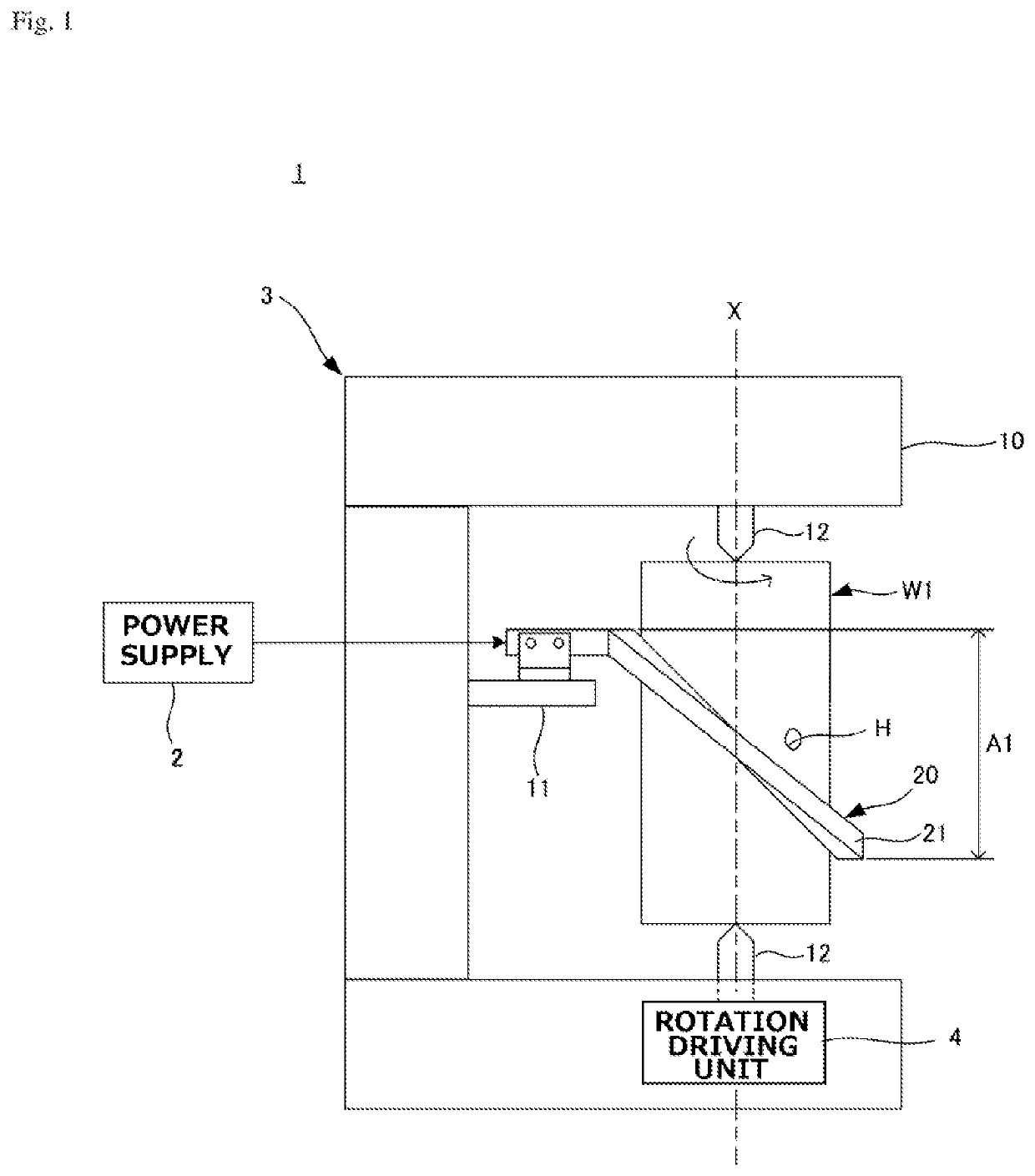

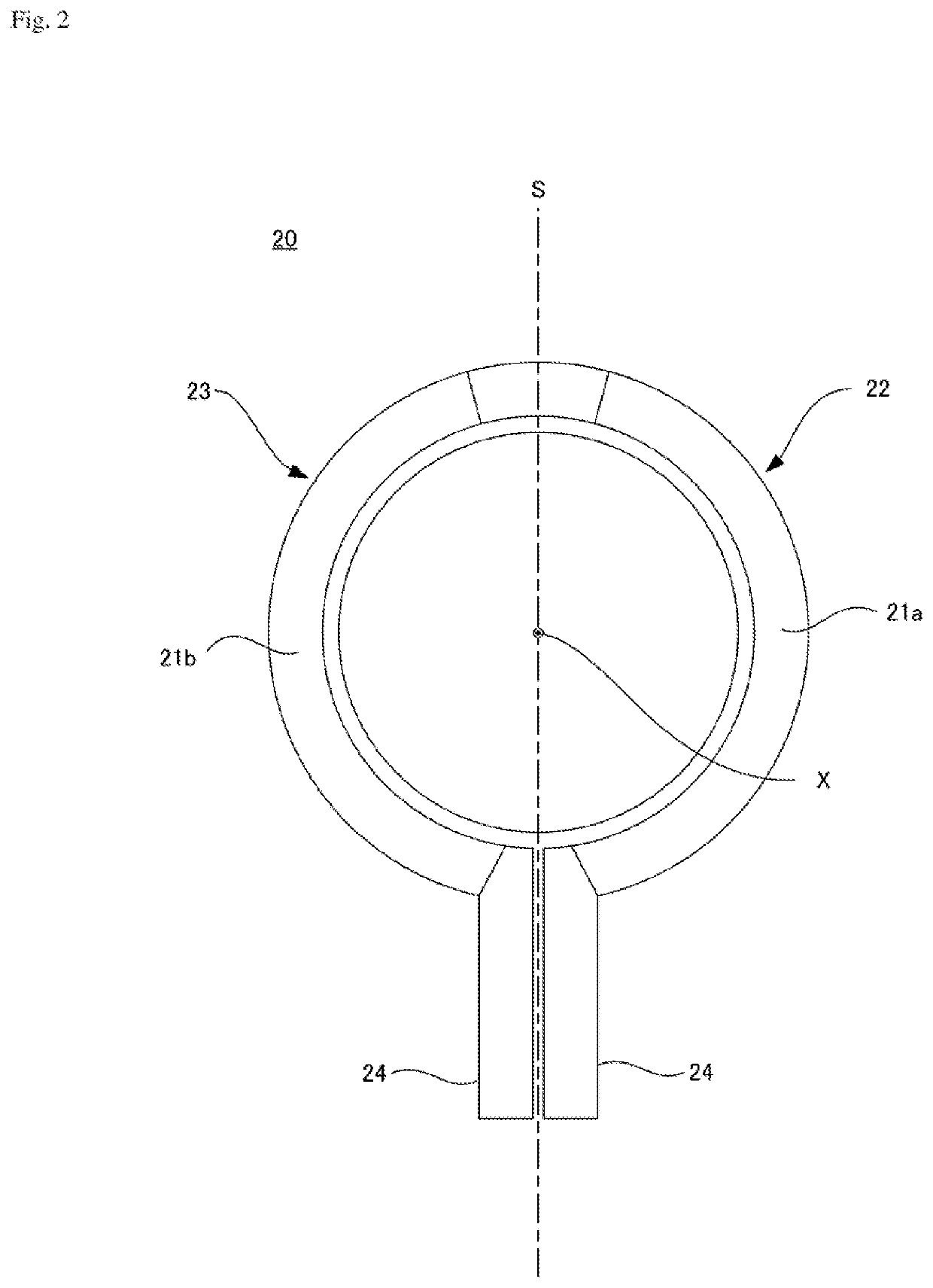

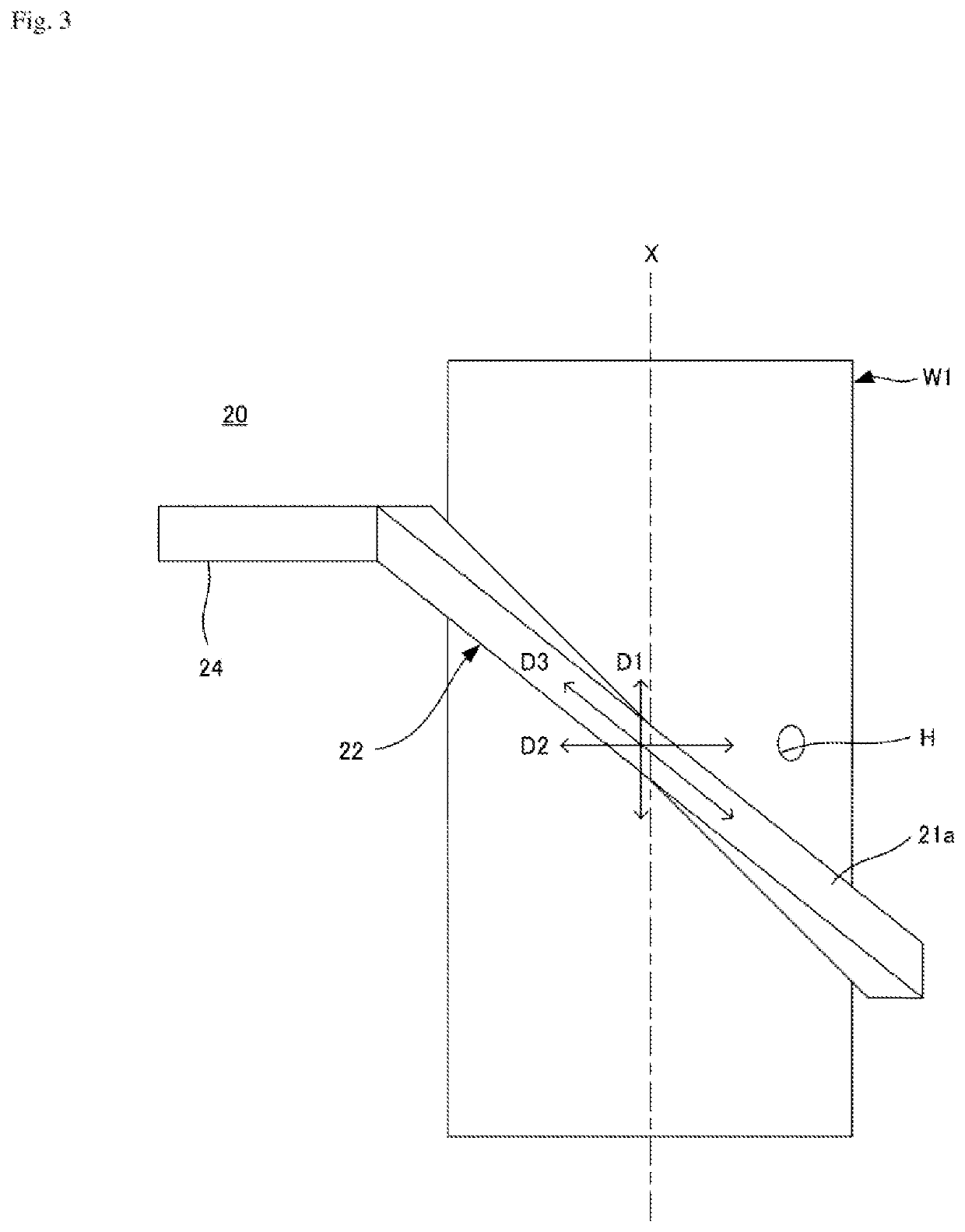

[0025]FIG. 1 schematically illustrates an example of a heating coil and a heating apparatus for illustrating an embodiment. FIGS. 2 to 4 illustrate the heating coil in FIG. 1.

[0026]A heating apparatus 1 is a stationary heating apparatus that is configured to inductively heat an outer peripheral surface of a cylindrical workpiece W1. A hole H extending in a radial direction from the outer peripheral surface is formed in the workpiece W1. The hole H may be a through hole or a blind hole.

[0027]The heating apparatus 1 includes a heating coil 20 that is configured to inductively heat the outer peripheral surface of the workpiece W1, a power supply 2 that is configured to supply high frequency AC power to the heating coil 20, a supporting portion 3 that is configured to support the workpiece W1 and the heating coil 20, and a rotation driving unit 4 that is configured to rotate the workpiece W1 about a central axis X of the workpiece W1.

[0028]The heating coil 20 is configured such that a cond

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap