Replaceable LED bulb with interchageable lens optic

a technology of interchageable lens and led bulb, which is applied in the direction of fixed installation, semiconductor devices for light sources, lighting and heating apparatus, etc., can solve the problems of uncomfortable viewing of led lamps by viewers, and achieve the effects of convenient replacement, good thermal contact, and convenient electrical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

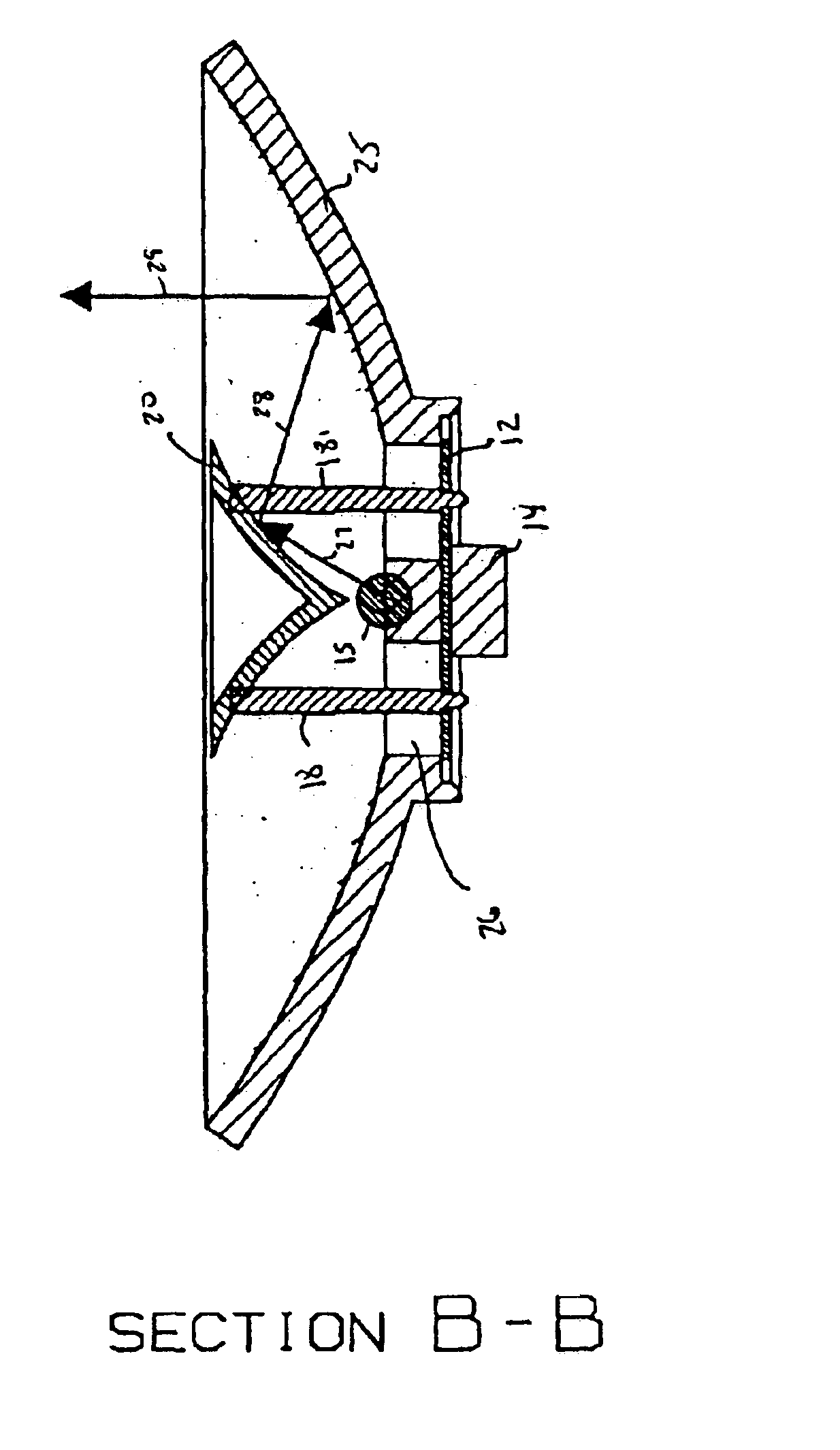

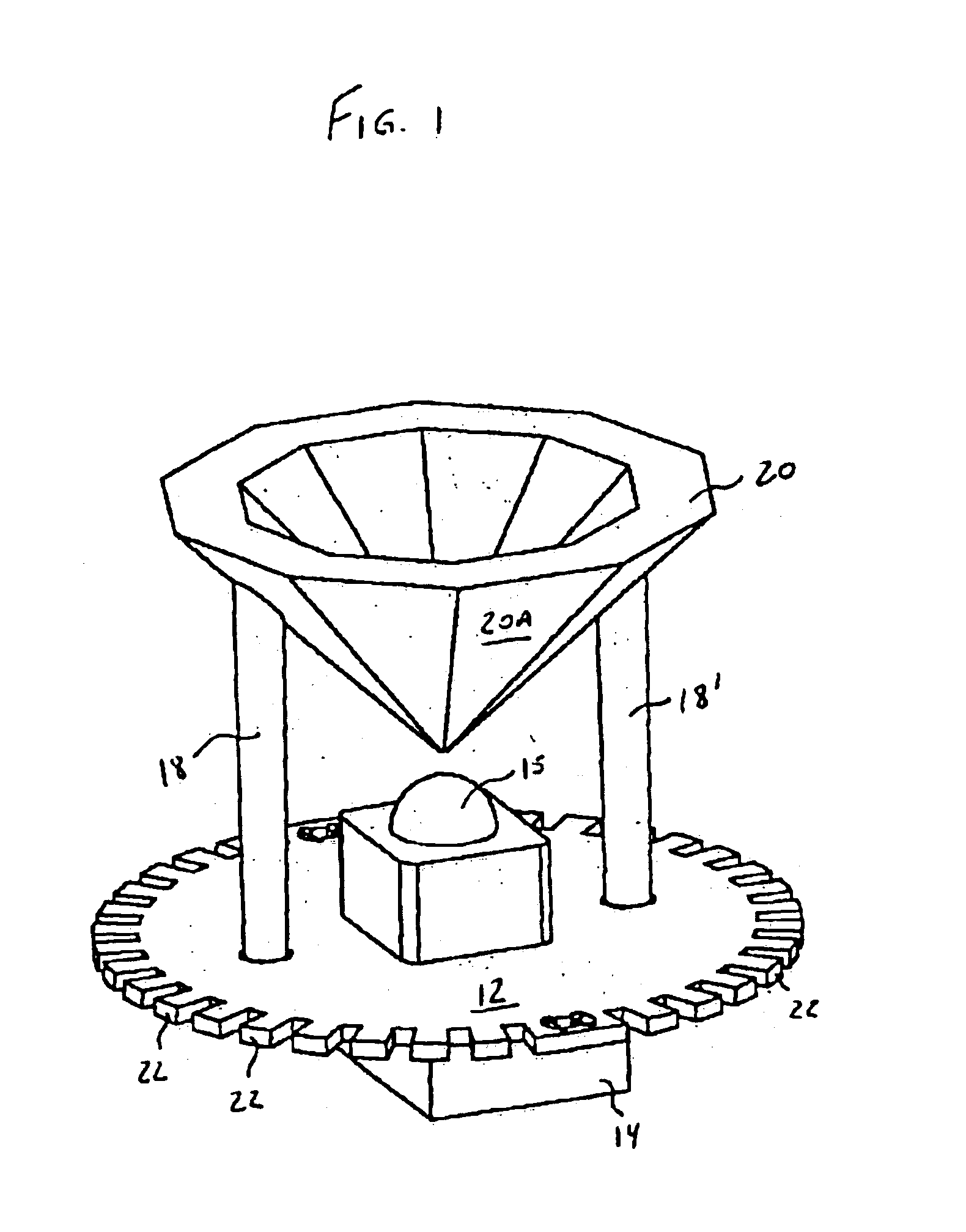

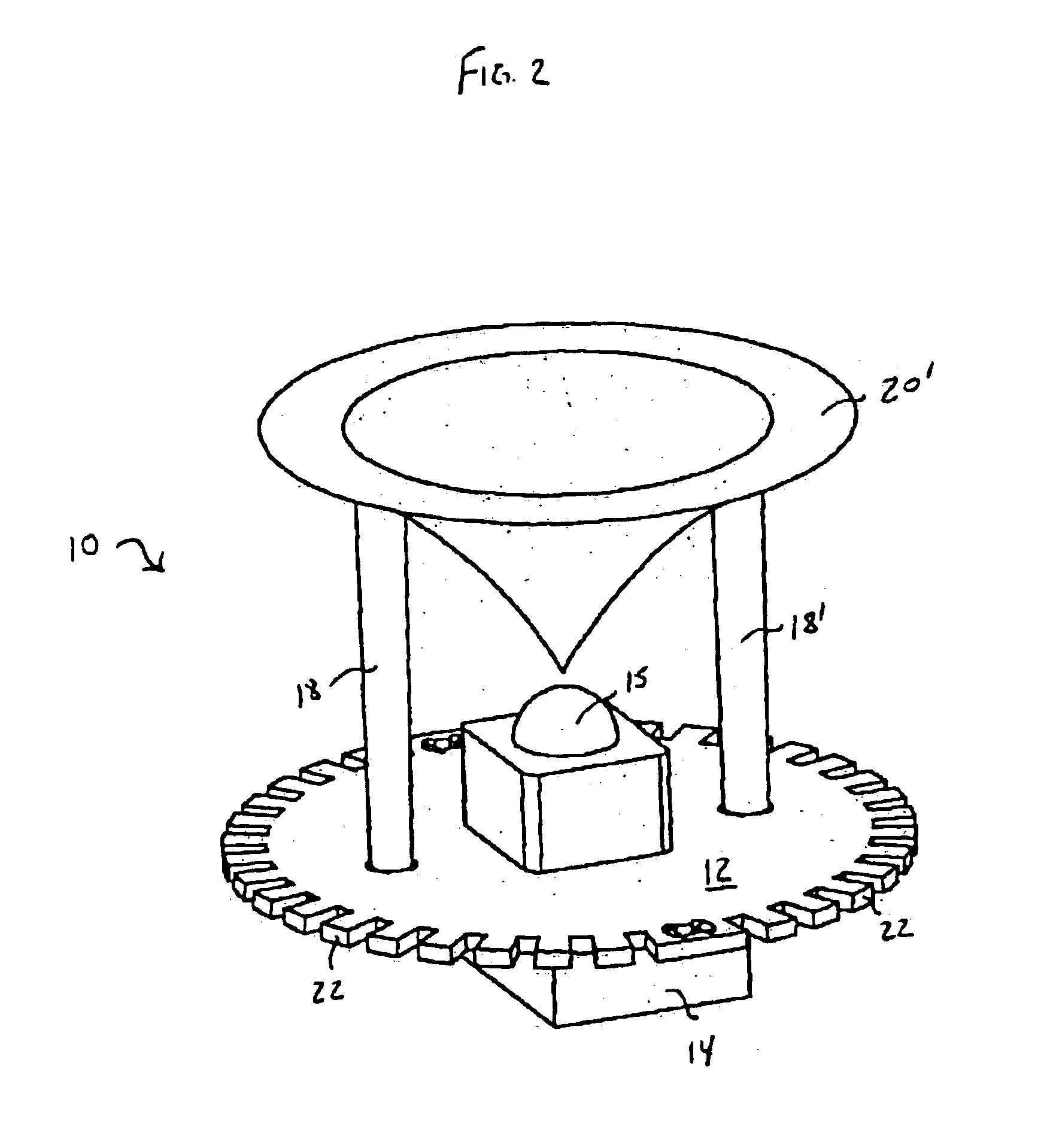

Turning first to FIG. 1, there is shown generally at 10 a lamp assembly in accordance with one embodiment of the present invention. The assembly includes a base plate 12, preferably made of metal so as to act as a heat sink. The base plate 12 can include a plurality of cooling fins 22 formed around its outer perimeter to assist in cooling the assembly. The shape of the cooling fins 22 is not particularly limited; for example, the fins 22 can taper towards their free end, be rounded at their corners, etc. The base plate 12 supports the LED light source or bulb 15 which is mounted to the plate by any suitable means. Positioned below or underneath the base plate 12 is an electric module 14 in electrical communication with the replaceable LED Bulb 15. Positioned above the LED bulb 15 is an optic or intermediate reflector 20. The optic 20 illustrated is a molded and metallized faceted. (depending in part on desired beam spread) optic, having an outer reflective surface 20A facing the light

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap