Device for removing inverter noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

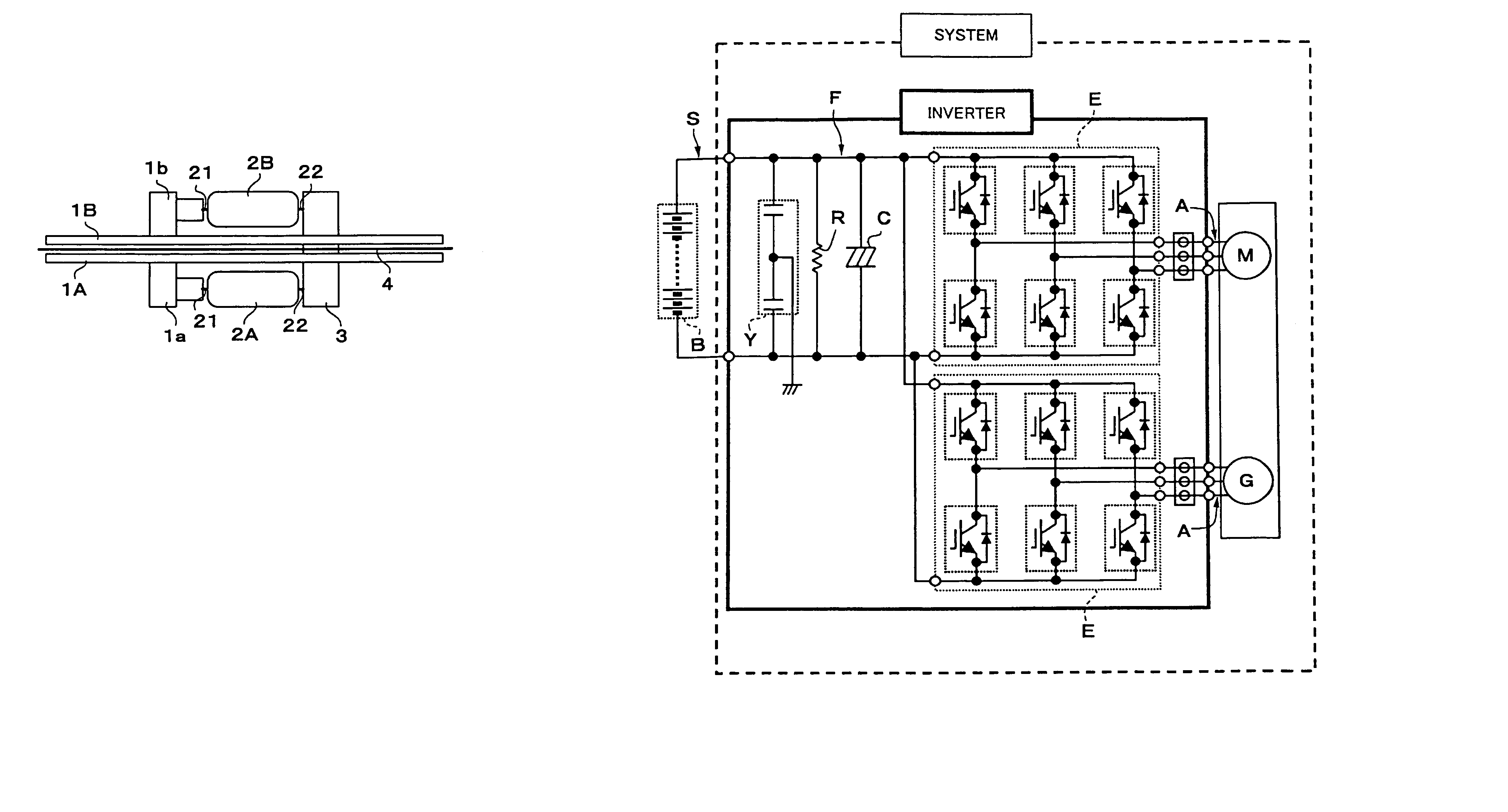

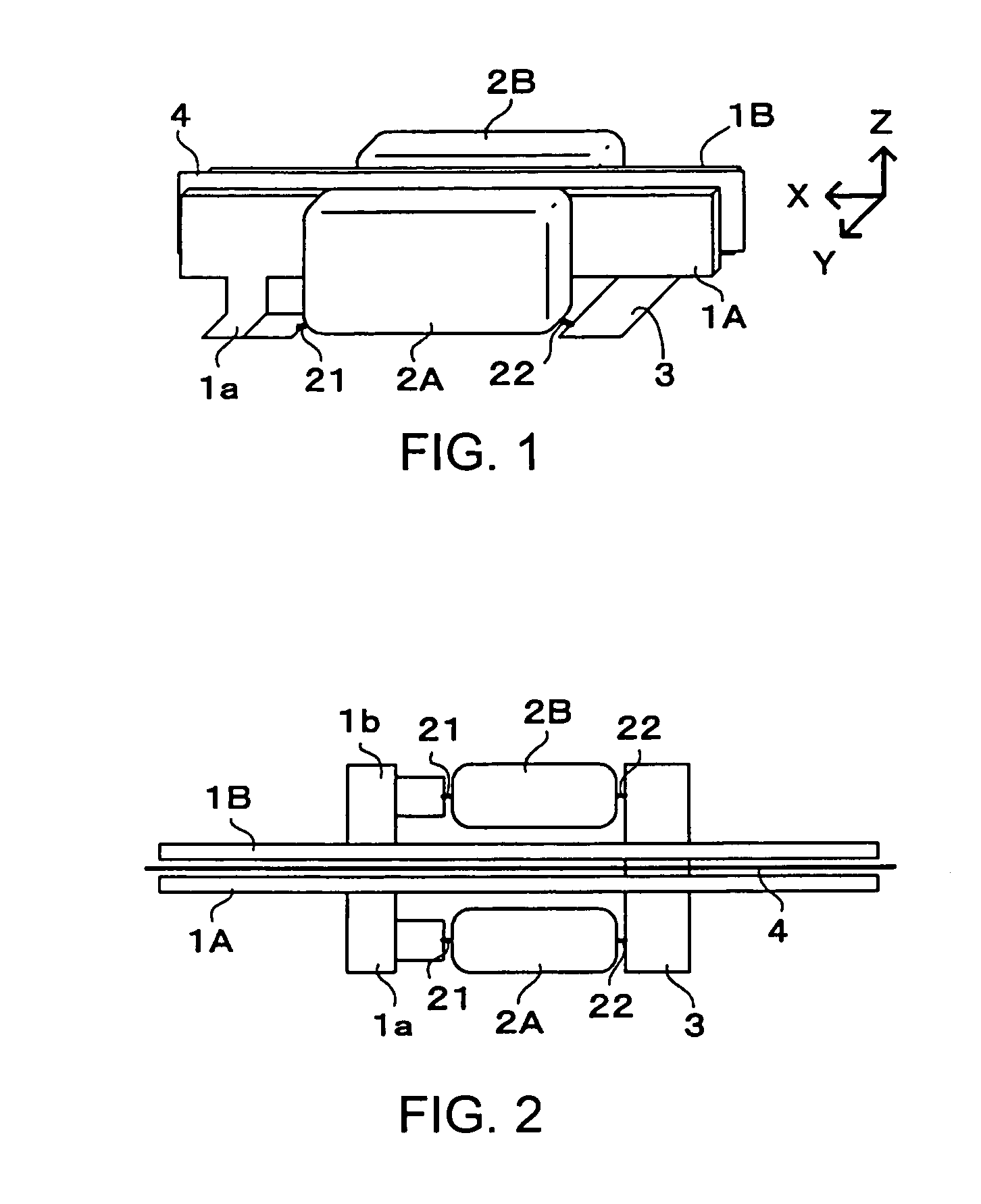

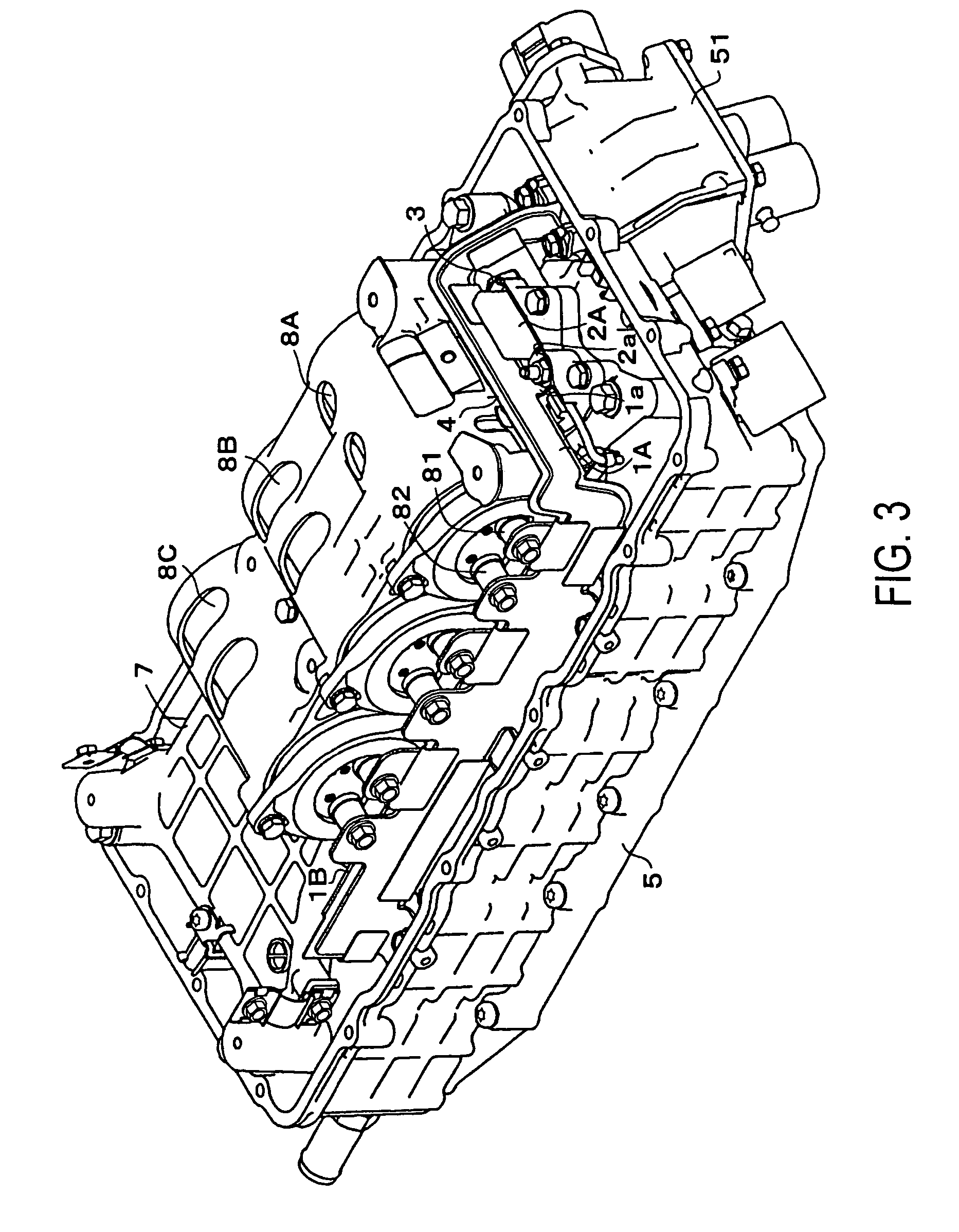

[0021]An embodiment of the invention will now be described with reference to the drawings. FIG. 1 is a perspective view schematically illustrating a device for removing inverter noise. The device is structured so as to ground a pair of bus bars 1A, 1B extending in parallel between a pair of capacitors 2A, 2B. The capacitors 2A, 2B are connected to the bus bars and to a grounding terminal 3 at symmetrical positions holding the pair of bus bars 1A, 1B therebetween. Because of this arrangement, the inductance component is substantially balanced up to a point grounded by the Y-capacitors 2A, 2B on the DC bus line connected to a converter circuit which is a source of noise. Besides, the impedance becomes very small in the front and rear connection lines holding the capacitors 2A, 2B therebetween. Therefore, this structure makes it possible to effectively remove high-frequency noise from the DC circuit of the inverter.

[0022]Here, the bus bars 1A, 1B are strap members with an insulating membe

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap