High-speed liquid dispensing modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

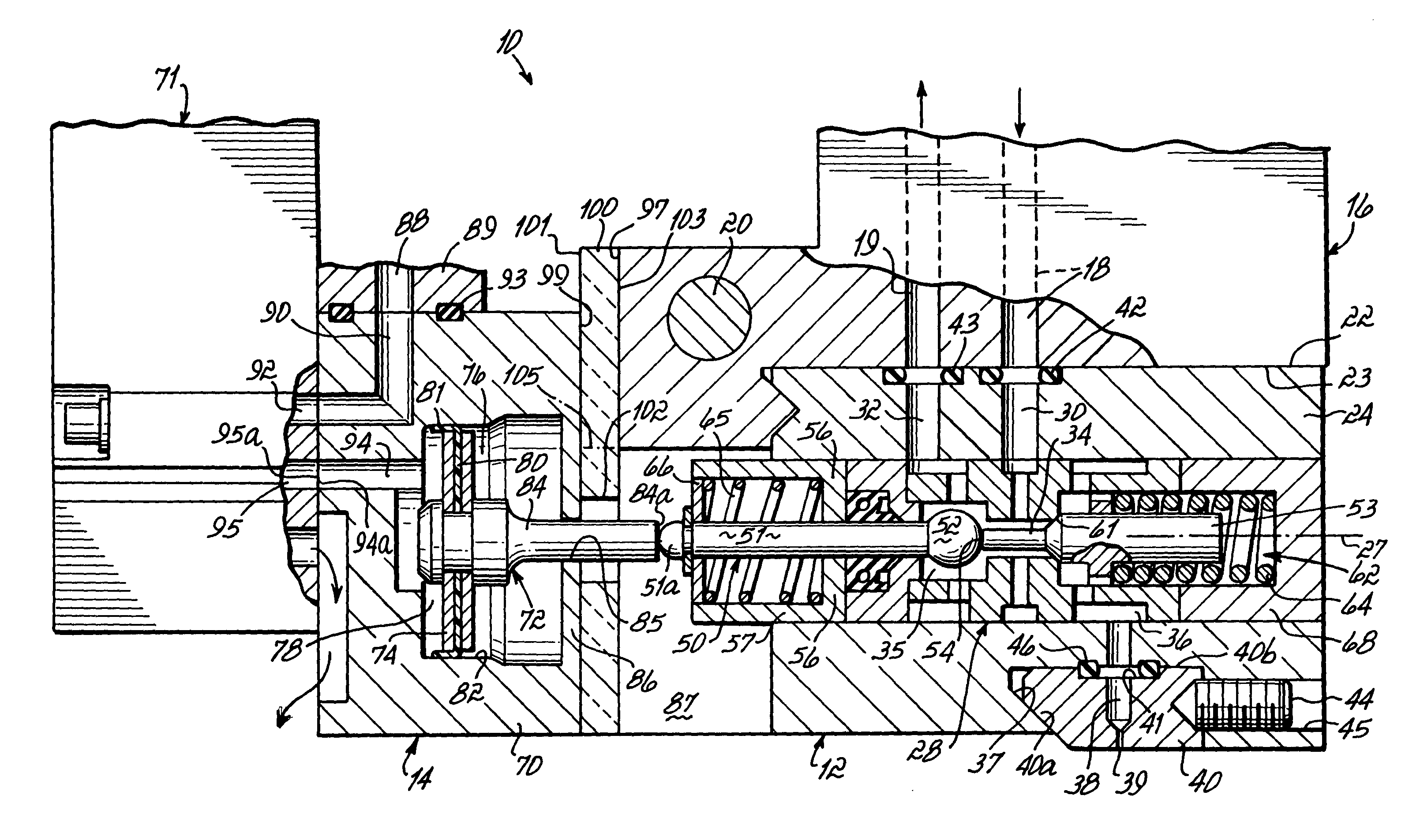

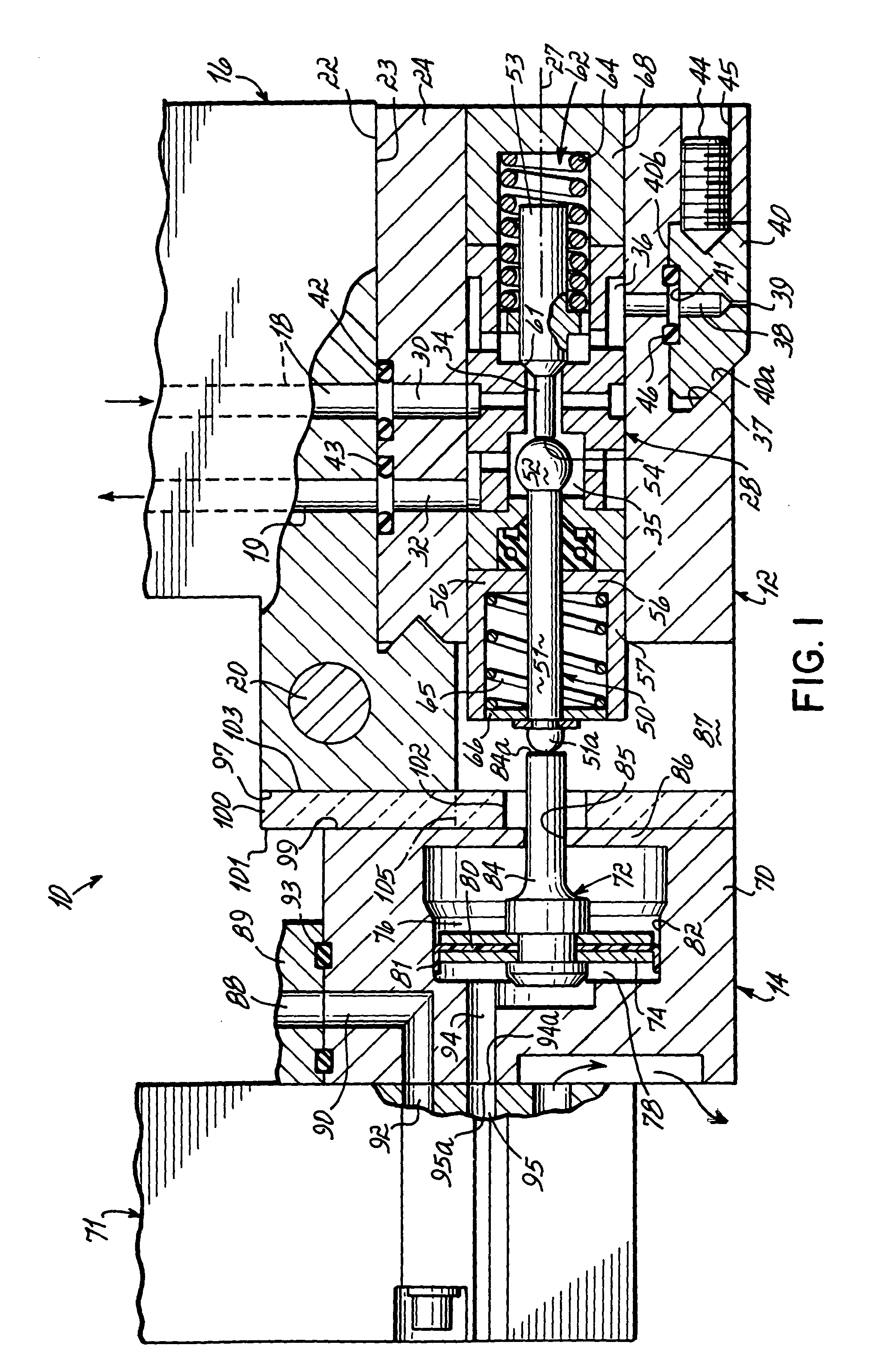

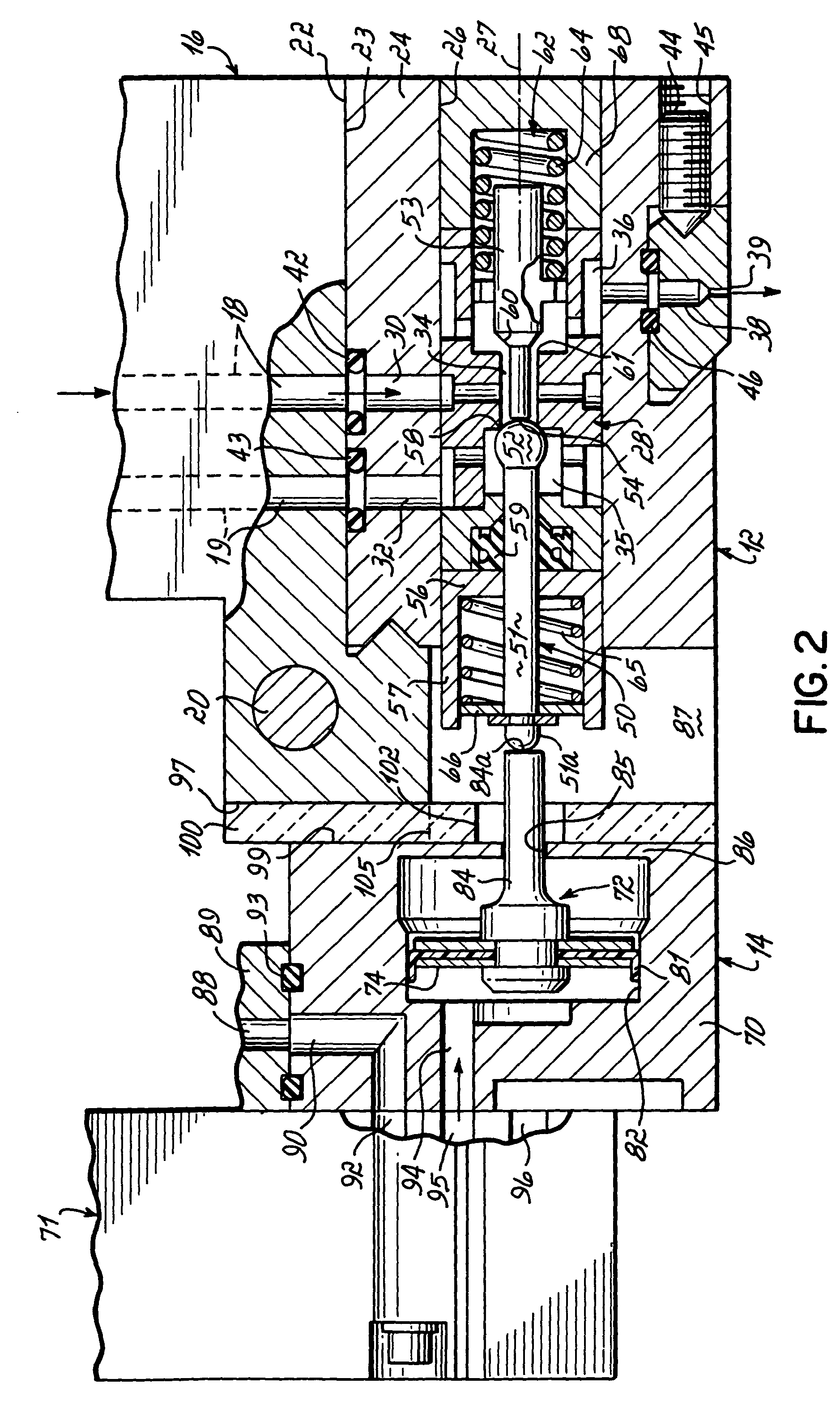

[0025]With reference to FIGS. 1 and 2, a liquid dispensing module 10 constructed in accordance with the principles of the present invention includes a dispenser body 12 and an actuator 14. The liquid dispensing module 10 is specifically adapted for dispensing a heated liquid, such as a molten thermoplastic hot melt adhesive. However, other heated liquid dispensing modules will also benefit from principles of the present invention. The liquid dispensing module 10 constitutes a flow control device adapted to accept a flow of a heated liquid and dispense the heated liquid in a controlled fashion onto a substrate. The liquid dispensing module 10 is configured to be actuated by the actuator 14 between an open position (FIG. 2), in which heated liquid is dispensed from the dispenser body 12, and a closed position (FIG. 1), in which the dispensing of heated liquid is halted.

[0026]The dispenser body 12 is mounted in a conventional manner to liquid distribution manifold 16. Liquid distribution

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap