Spark plug connector

a technology of spark plugs and connectors, which is applied in the direction of engine ignition, coupling device connections, other installations, etc., can solve the problems of high heating problems, unnecessarily high quantity of useful energy, and components such as spark plug connectors, and achieves low resistance to the lower-frequency useful energy, improve the energy balance, and reduce the effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

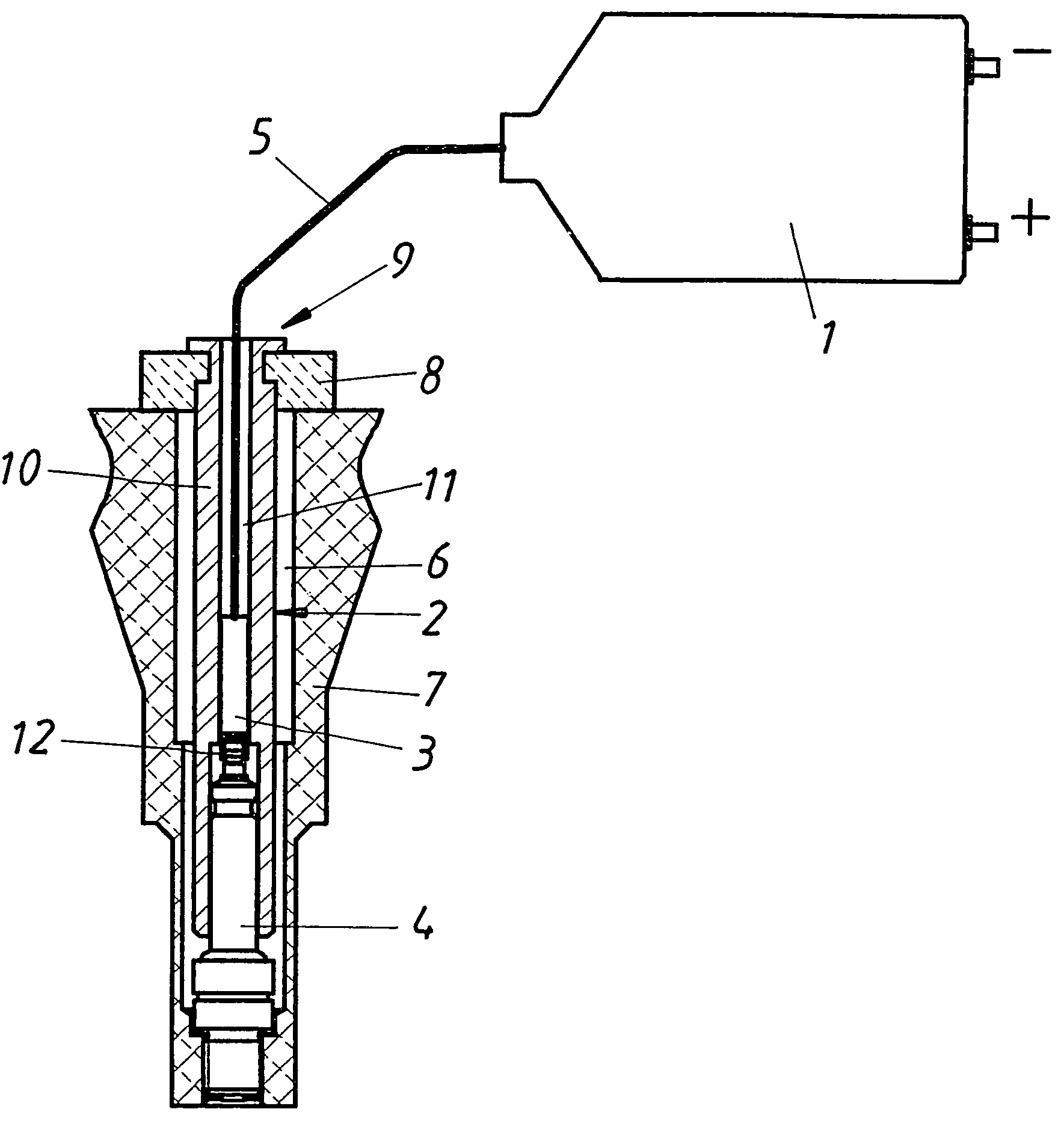

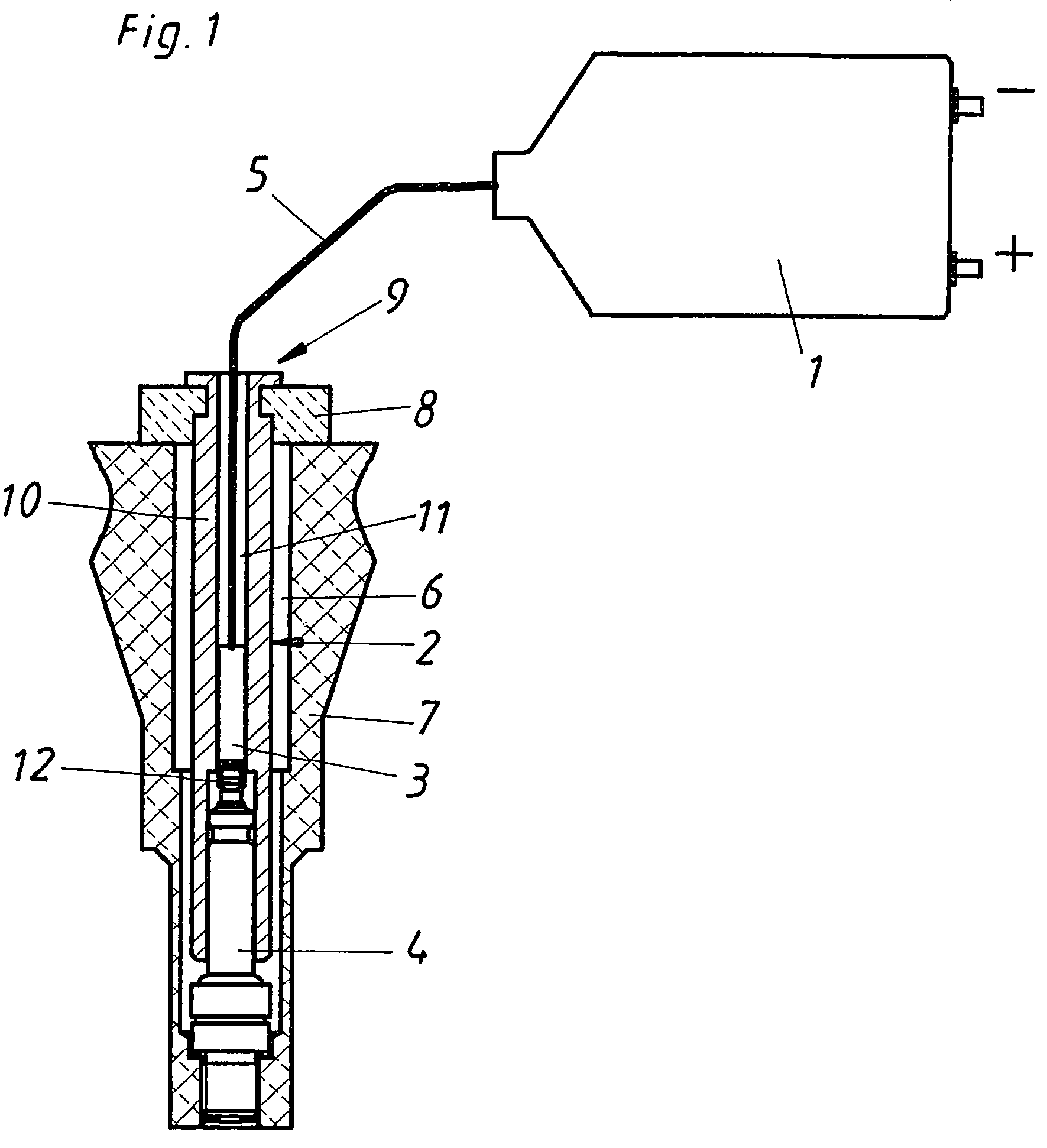

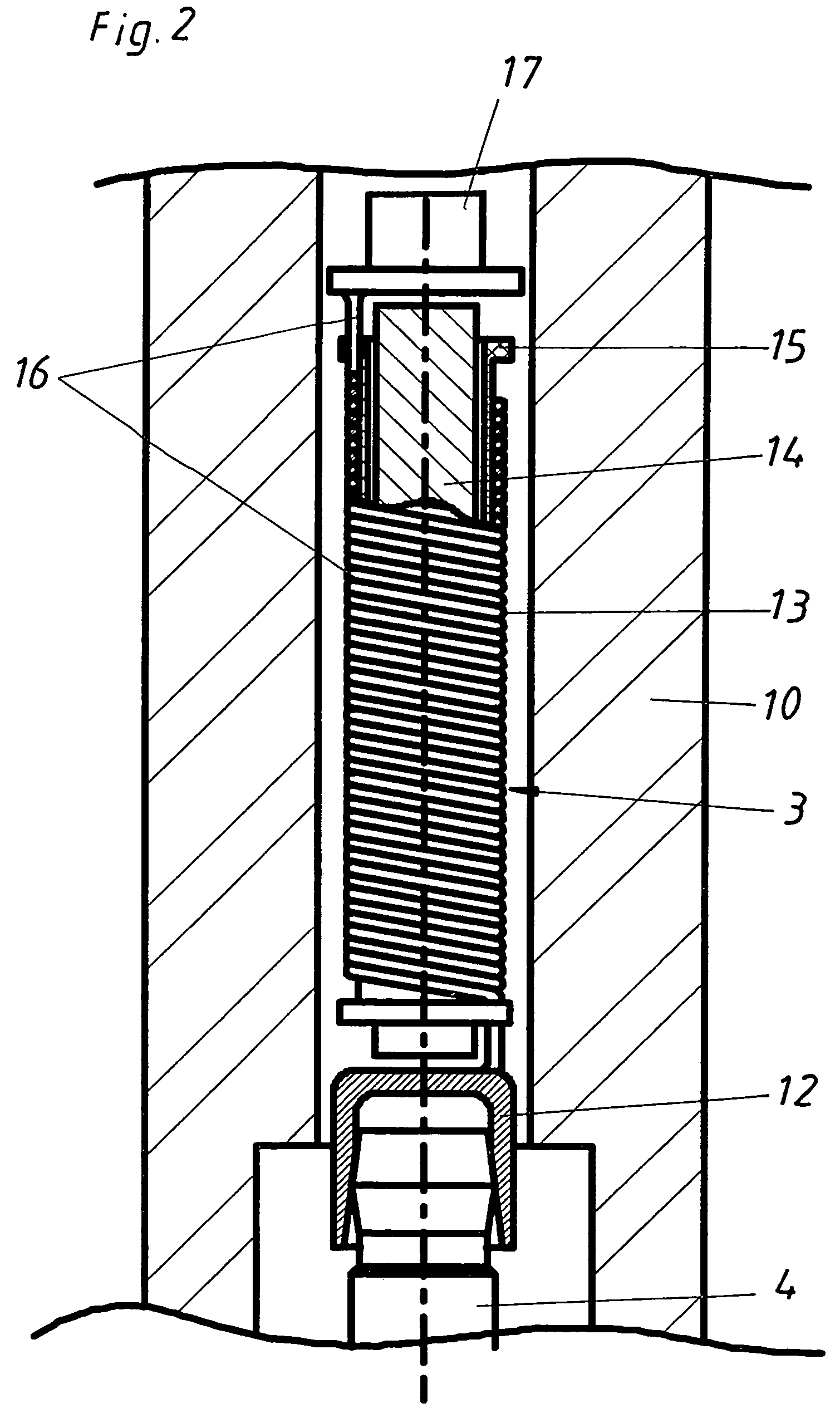

[0013]FIG. 1 shows a structure, in accordance with the invention, in a diagrammatic sectional illustration. The ignition coil 1 is illustrated in a highly simplified manner and may be constructed as known from the prior art. A spark plug lead 5 leads from the ignition coil 1 into the spark plug connector 2, which is arranged in a bore 6 in the engine block 7 and is pushed onto a spark plug 4. Conventionally, there is a plug contact on the end of the spark plug connector 2 remote from the spark plug 4, and the plug contact serves to connect the spark plug 4 to an external spark plug lead cable 5. This detail is not illustrated here, but may be constructed as known from the prior art. Preferably, the spark plug connector is a separate component from the ignition coil 1. As a result of this, unnecessary loads on the ignition coil arising from vibration and heat are avoided, since the ignition coil can be arranged at a remote location, connected to the spark plug connector 2 by way of the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap