Electrically conductive polymeric biomaterials, the process for their preparation and the use thereof in the biomedical and healthcare field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

Synthesis of Thin Films of PPy / PSS

[0031]The synthesis of thin films based on polypyrrole doped with polystyrene sulphonate was performed by both the potentiostatic and galvanostatic methods. For both these synthesis procedures the relative thickness adjusted to the surfaces of the electrodes used and for the current in the cell are reported in Table 1. For these films the thickness were determined indirectly by a procedure devised by Diaz and co-workers (“Handbook of conducting polymers”, Diaz & Burgon, vol 1, 81; Ed. Terje A. Skotheim).

[0032]The starting electrolytic solutions were prepared using concentrations of anion, lyophilised and in the form of sodium salt, varying between 0.05.0.2M and concentrations of pyrrole between 0.05 and 0.3M. In this way the optimal conditions were established for obtaining films that were homogeneous and easily separable from the working electrode, in order to be able to characterise them from a chemical-physical point of view. This procedure was re

example 2

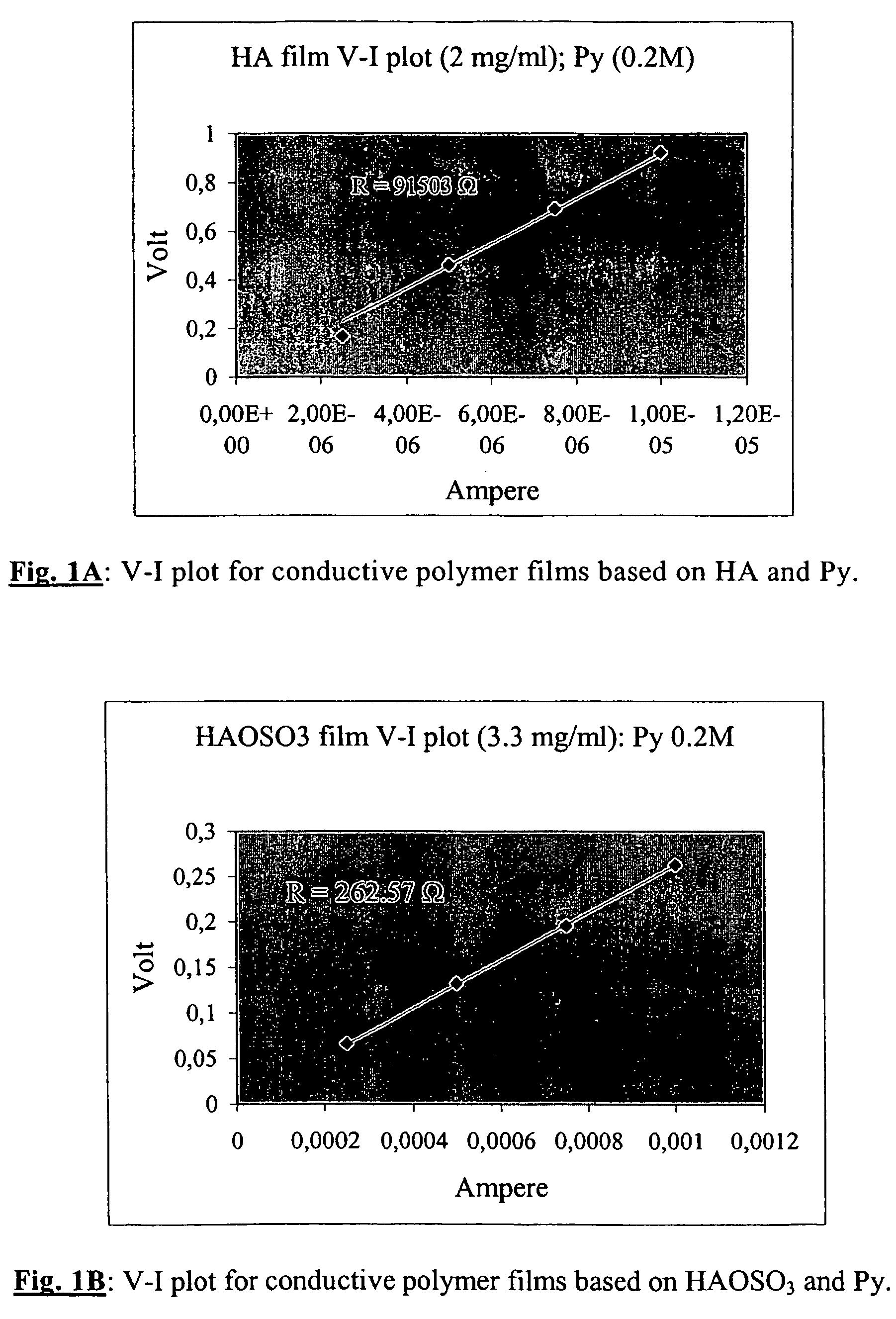

Synthesis of Thin Films of PPy / HA

[0036]Conductive polymer films based on PPy and HA were synthesised both by a galvanostatic method, applying current at a constant intensity ranging between 0.5 and 10 mA and for periods varying between 60 and 150 minutes, and by the potentiostatic method, using constant potentials ranging between 0.3-0.75 V vs. SCE. The first method was chosen to conduct most of the syntheses, because it enabled us to obtain films with even surfaces, notably reducing the reaction times. The polymer films were synthesised in aqueous solutions using concentrations of Py varying between 0.05 and 0.3 M and concentrations of HA (lyophilised and in the form of a sodium salt: HA− / Na+) ranging between 0.9 and 5 mg / ml. Table 2 below reports the methods and the experimental conditions:

[0037]

TABLE 2Type of filmMethodThickness (μm)HA 2 mg / ml, Py 0.1MPotentiostatic0.33V = 720 mV vs SCE, 0.19 CHA 2 mg / ml, Py 0.1MGalvanostatic4.2Total charge → 1 CHA 2 mg / ml, Py 0.1MGalvan

example 3

Synthesis of Thin Films of PPy / HAOSO3

[0038]During synthesis, a sulphated derivative of HA, lyophilised and in the form of a sodium salt (HAOSO3 / Na) was used as doping agent for polypyrrole, in order to increase the interaction between the positive charges constituting the bipolar system of polypyrrole and the negative charges present along the polysaccharide chain. This new compound gave far better results in terms of electric conduction (see example 4) than the films of PPy / HA. For this type of synthesis we used electrolytic solutions with different molar concentrations of polysaccharide (0.95-5 mg / ml), calculated with regard to the mean degree of sulphation of the repetitive unit of HA.

[0039]Unlike the films obtained using HA as such, those based on sulphated HA are more homogeneous and simpler to synthesise. The results reported in Table 3 refer exclusively to films of PPy / HAOSO3− in which the polysaccharide is present both at the same molar concentration (moles calculate

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap