Optimizing a chemical reaction in a plate-type open reactor

a technology of open reactor and chemical reaction, which is applied in the field of optimizing a chemical reaction in an open reactor of plate type, can solve the problems of removing heat and putting constraints on controlling and optimizing the reaction, and achieve the effect of simple and effectiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

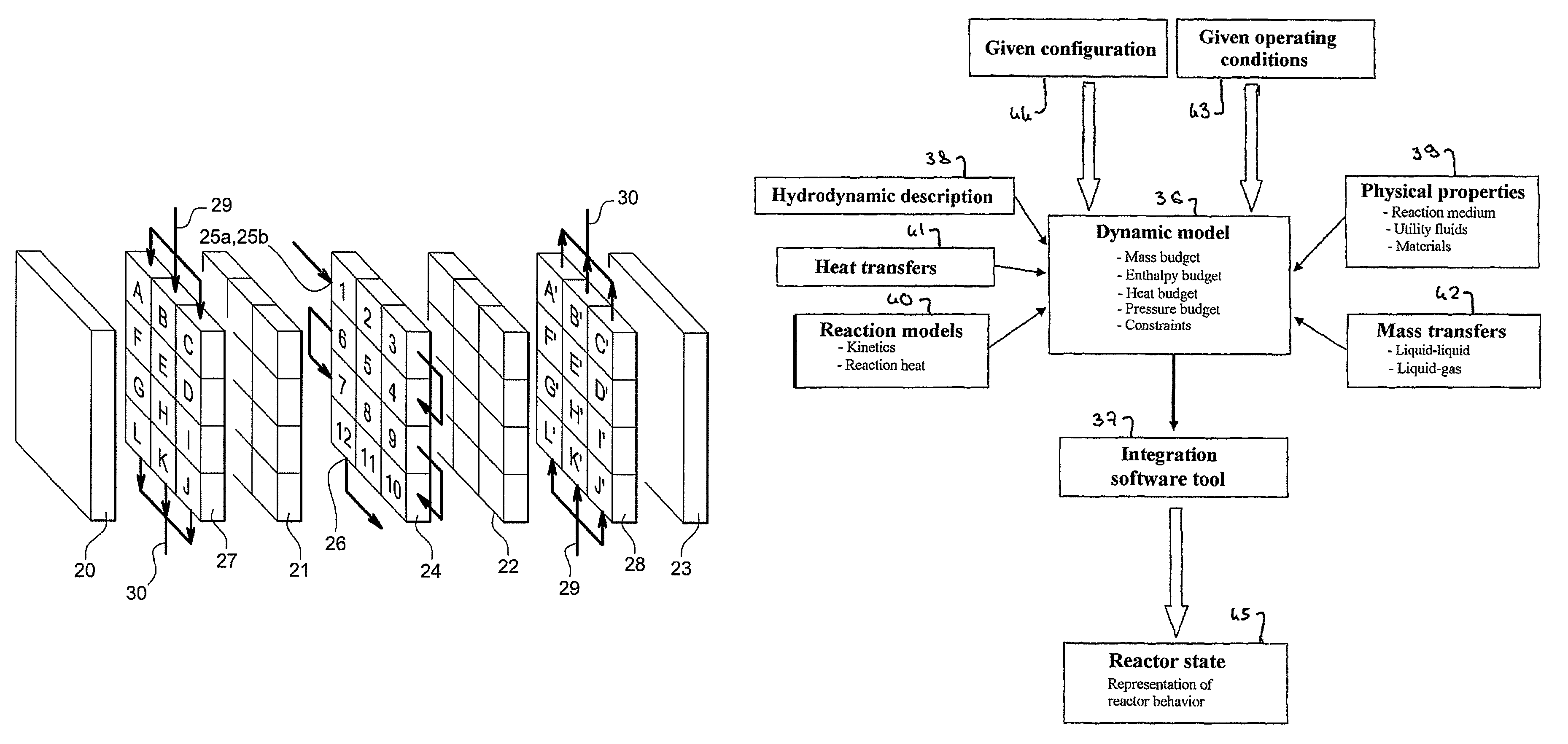

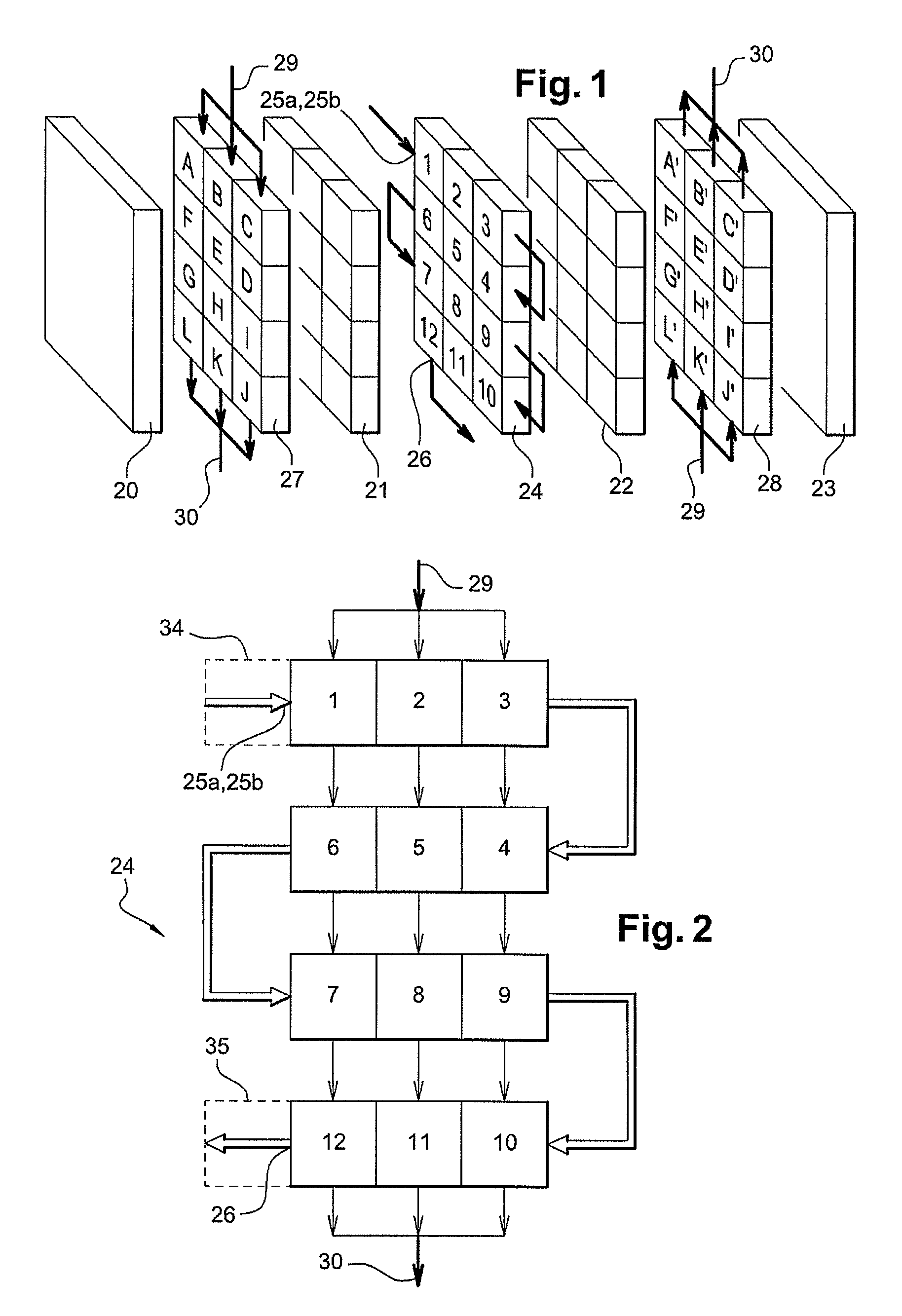

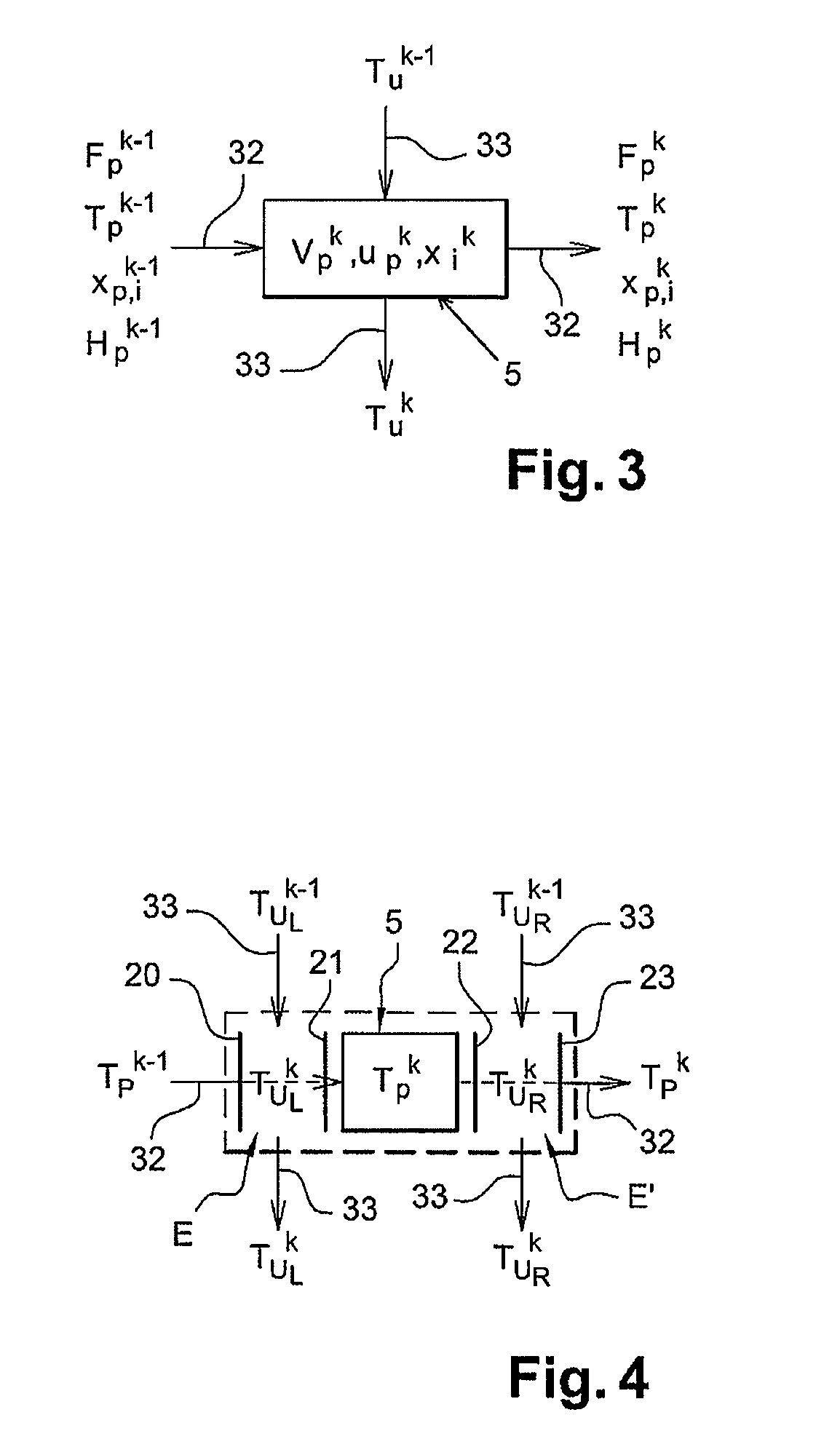

[0054]Reference is made initially to FIG. 1 which is a diagram of an open or continuous reactor comprising a stack of plates 20, 21, 22, 23 which define parallel chambers between one another. The plates 21 and 22 are referred to as “transition” plates and they define between them a reaction chamber 24 having a reagent feed point 25a and one or more feed points 25b for one or more other reagents, and an outlet point 26 for the product(s) of the reaction. The plates 20 and 23 are adiabatic plates and they co-operate with the plates 21 and 22 to define a left side chamber 27 and a right side chamber 28 for circulating a heat exchange utility fluid, each side chamber 27, 28 having an inlet 29 and an outlet 30 for the utility fluid.

[0055]The utility fluid which circulates in the left side chamber 27 may be identical to or different from that which circulates in the right side chamber 28, and the utility fluid that is commonly used is water or ethylene glycol.

[0056]The stack of plates 20, 21

PUM

Login to view more

Login to view more Abstract

- establishing a dynamic model of the reactor for a given reaction on the basis of a model of the reactor and its heat exchanges;

- applying an integration software tool to the dynamic model in order to solve the above-mentioned equations;

- determining and optimizing a set of dimension and/or operation parameters of the reactor on the basis of evaluating targets to be achieved, constraints to be complied with, and variable data for the reactor and/or the reaction;

- building a plate reactor of the said type accordingly to the set of optimized parameters; and

- doing measurements of physical parameters during the execution of said reaction in the built reactor, for validating its operation.

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap