Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Gas analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

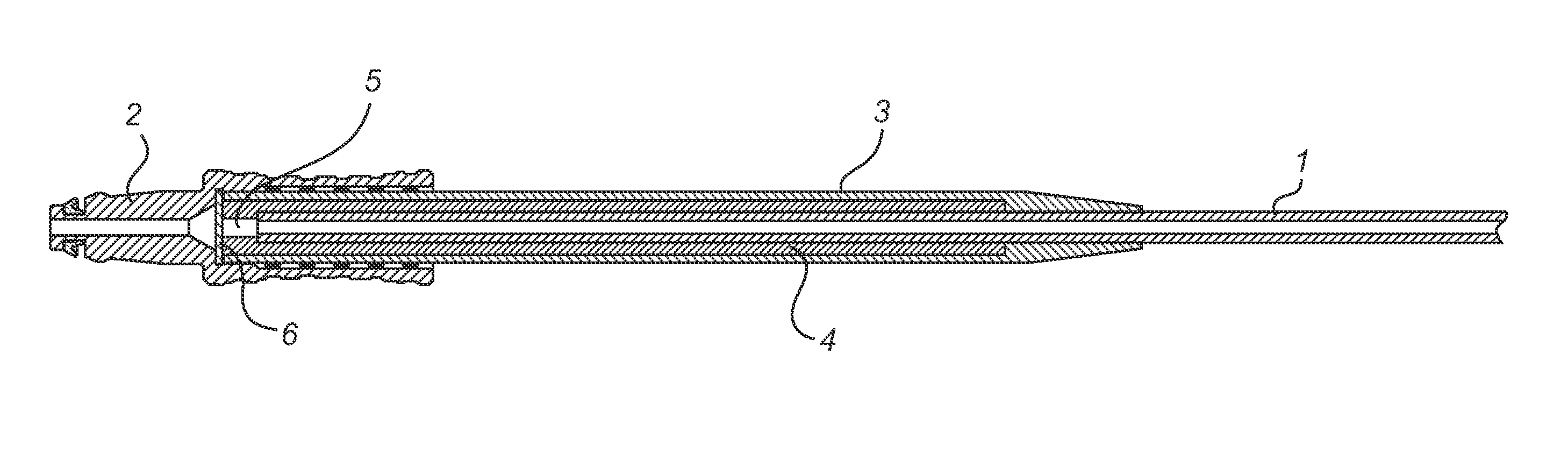

Gas sampling line

ActiveUS20110237969A1Improve accuracyReduce distortion problemsDispersed particle separationRespiratory organ evaluationGas analysisPolyethylene oxide

Owner:JPMORGAN CHASE BANK NA

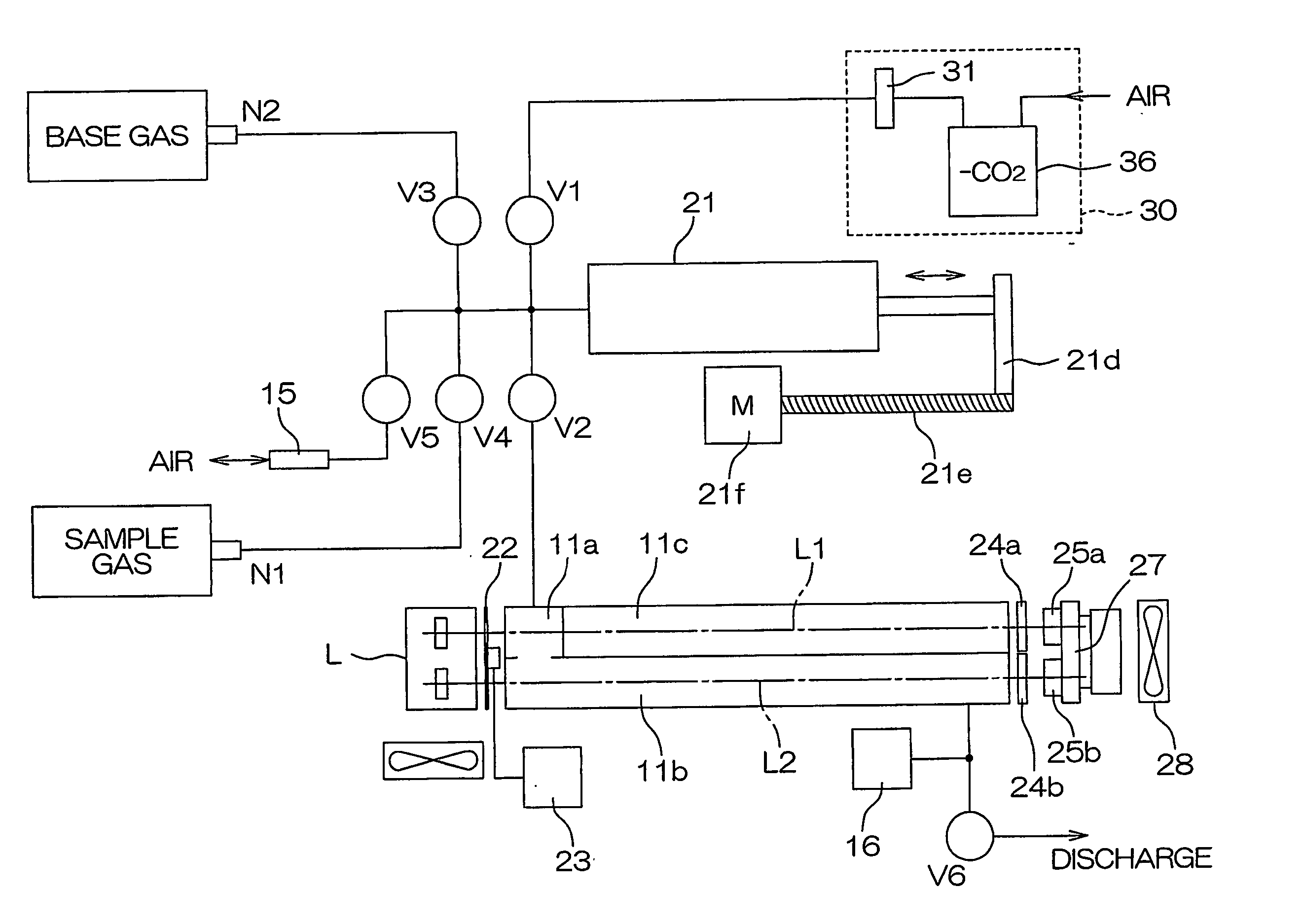

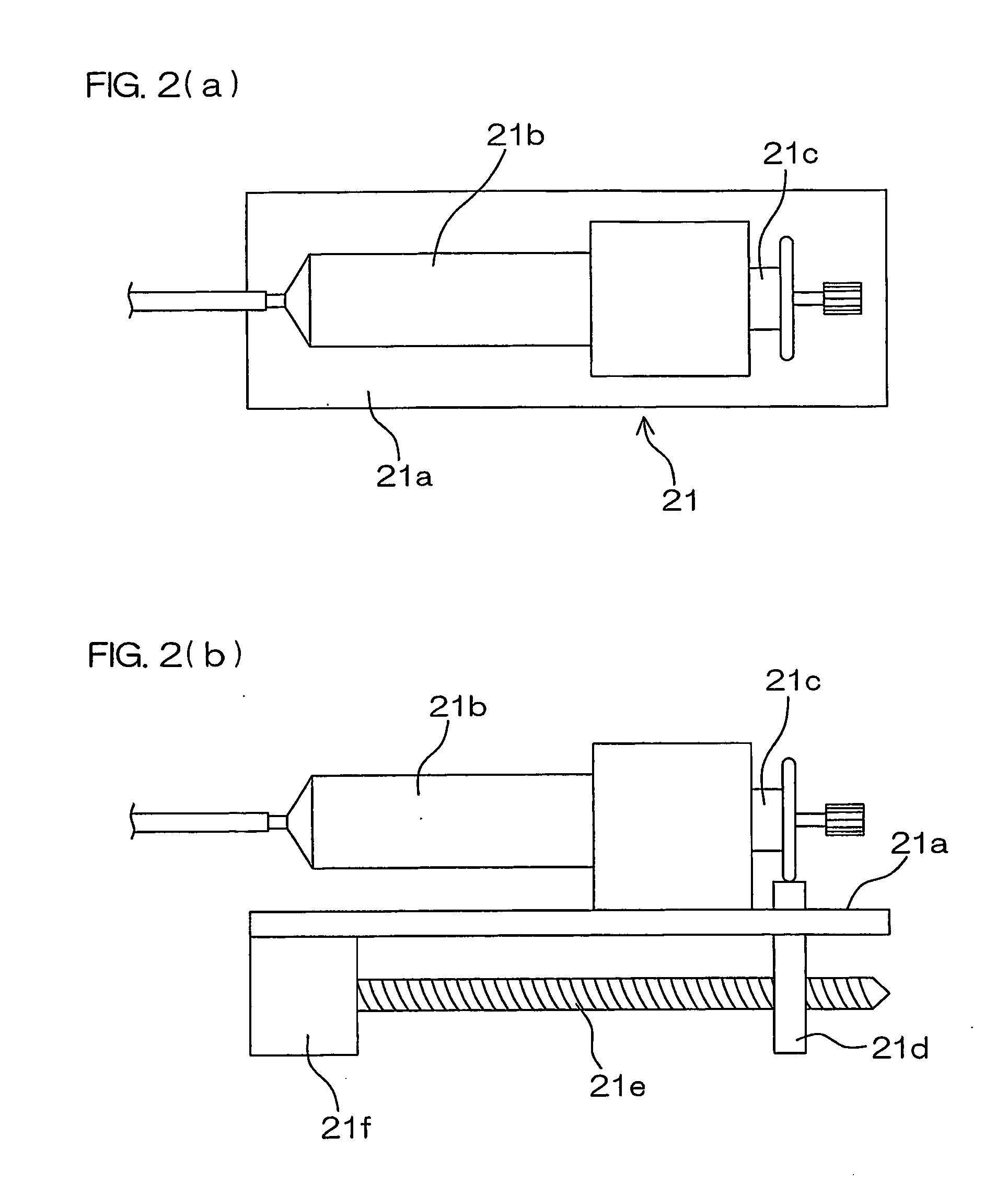

Gas injection amount determining method method in isotope gas analysis, and, isotype gas analyzing and measuring method and apparatus

ActiveUS20070077167A1Improve precisionGood reproducibilityWeather/light/corrosion resistanceWithdrawing sample devicesGas analysisExhaust valve

Owner:OTSUKA PHARM CO LTD

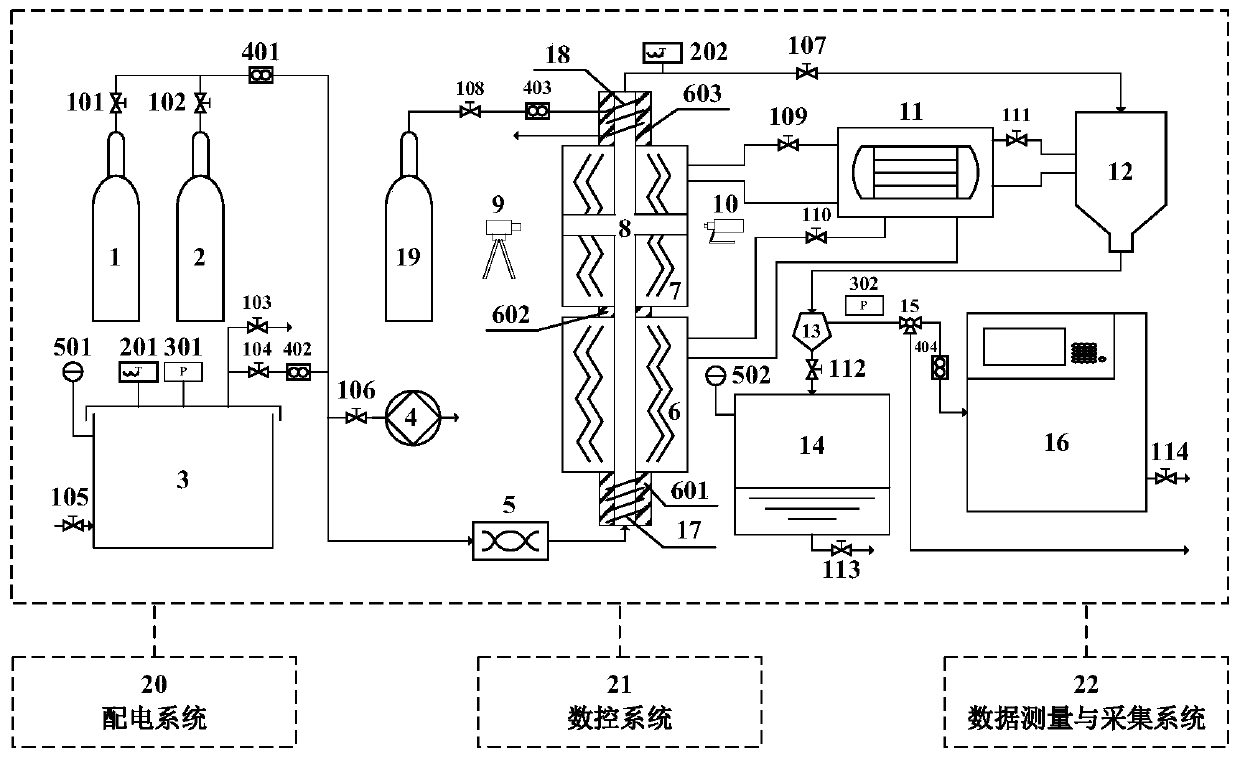

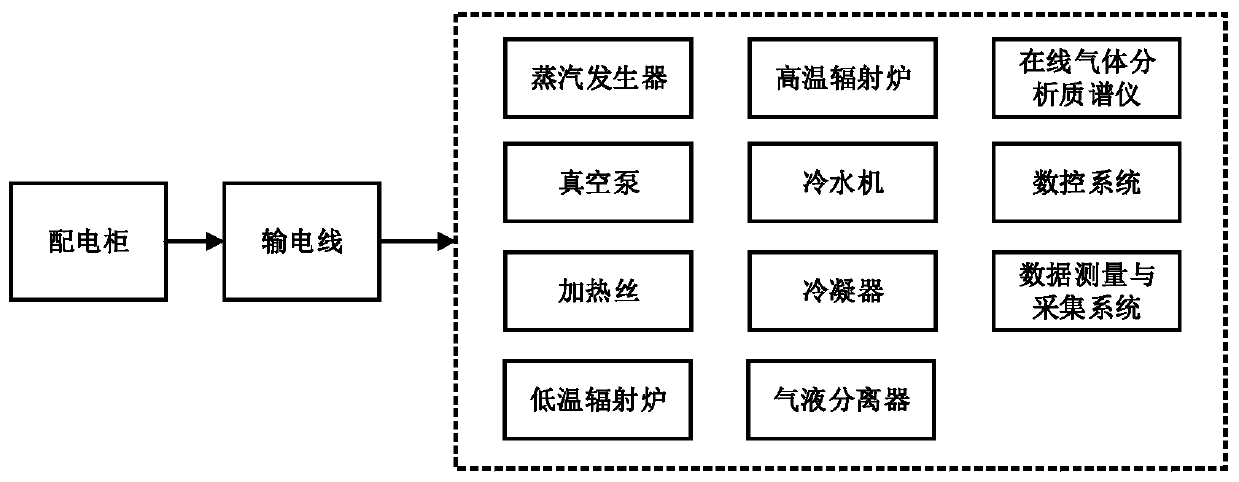

Structural material ultra-high temperature corrosion experiment system and method under serious accident of nuclear reactor

ActiveCN110553974AReduce space consumptionGuaranteed tightnessWeather/light/corrosion resistanceMaterial analysis by electric/magnetic meansContinuous measurementCorrosion reaction

Owner:XI AN JIAOTONG UNIV

Gas analysis apparatus

InactiveUS20170336375A1Check valvesMaterial analysis by electric/magnetic meansGas analysisEngineering

In a gas analysis apparatus including analyzers that need ignition, such as FIDs, in order to make it possible to surely ignite the analyzers while downsizing the entire apparatus, the apparatus includes first and second analyzers to accept a sample gas, a first gas line provided with the first analyzer, a second gas line provided with the second analyzer and joined downstream of the first analyzer in the first gas line. At least one of the first analyzer and the second analyzer is configured to cause pressure fluctuations in the gas line including the analyzer when analyzing the sample gas. A first backflow prevention mechanism is disposed between another of the analyzers and a junction of the gas lines. The first backflow prevention mechanism is configured to prevent a fluid from flowing backward from the one of the analyzers through the junction toward the another of the analyzers.

Owner:HORIBA LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap