Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7 results about "Level line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

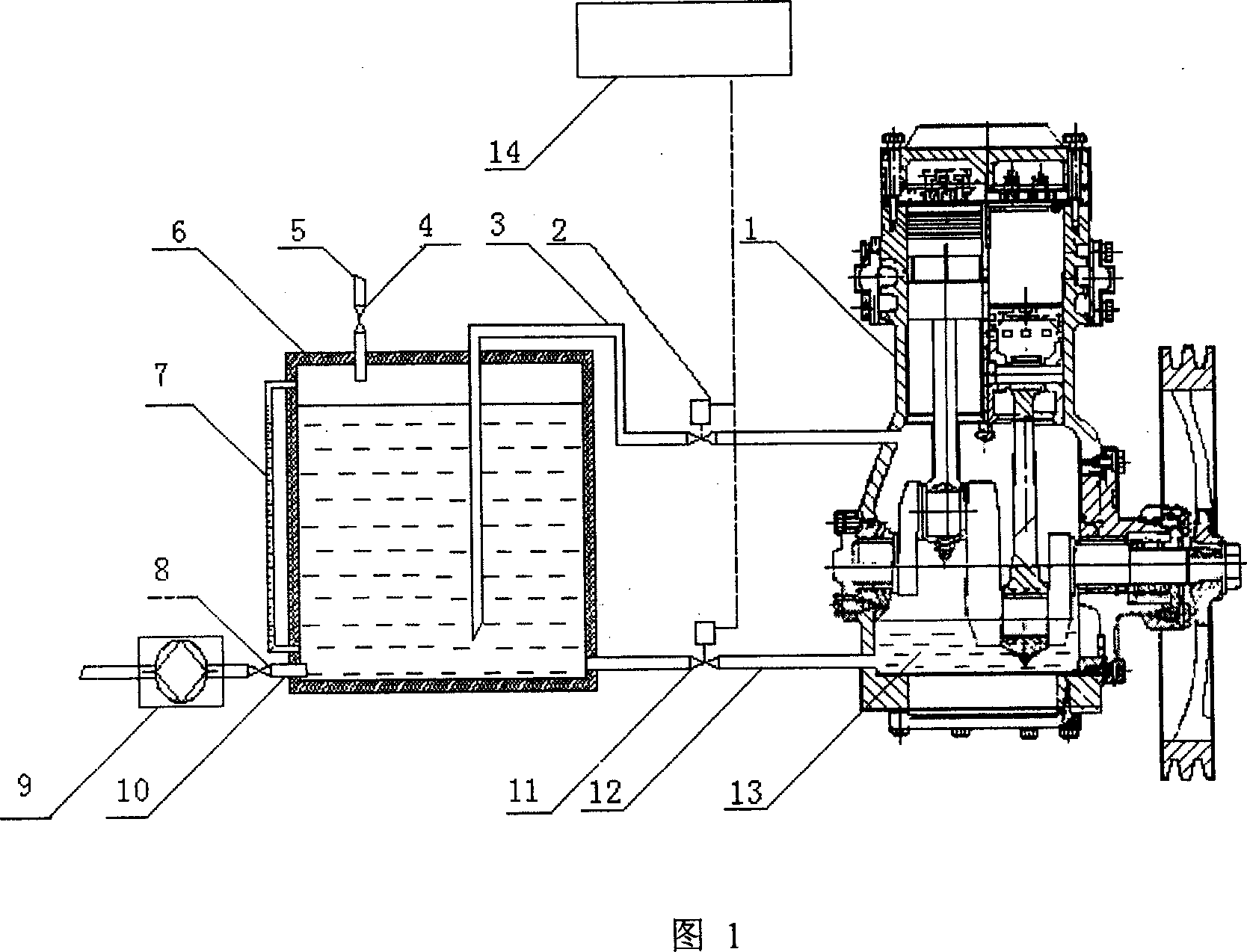

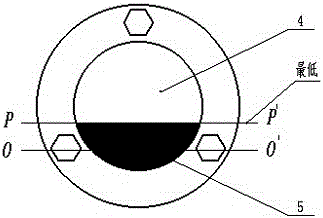

Automatic balance and compensating device for refrigeration compressor oil level

InactiveCN1945014APositive displacement pump componentsPositive-displacement liquid enginesLevel lineFuel tank

Owner:SOUTHEAST UNIV

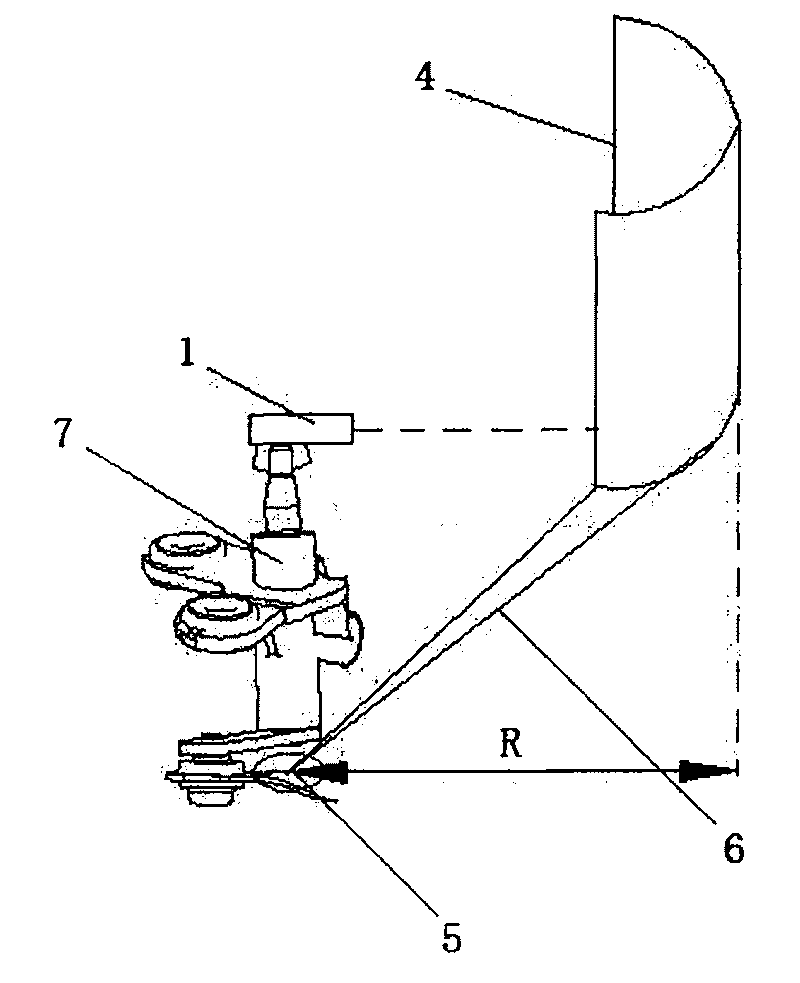

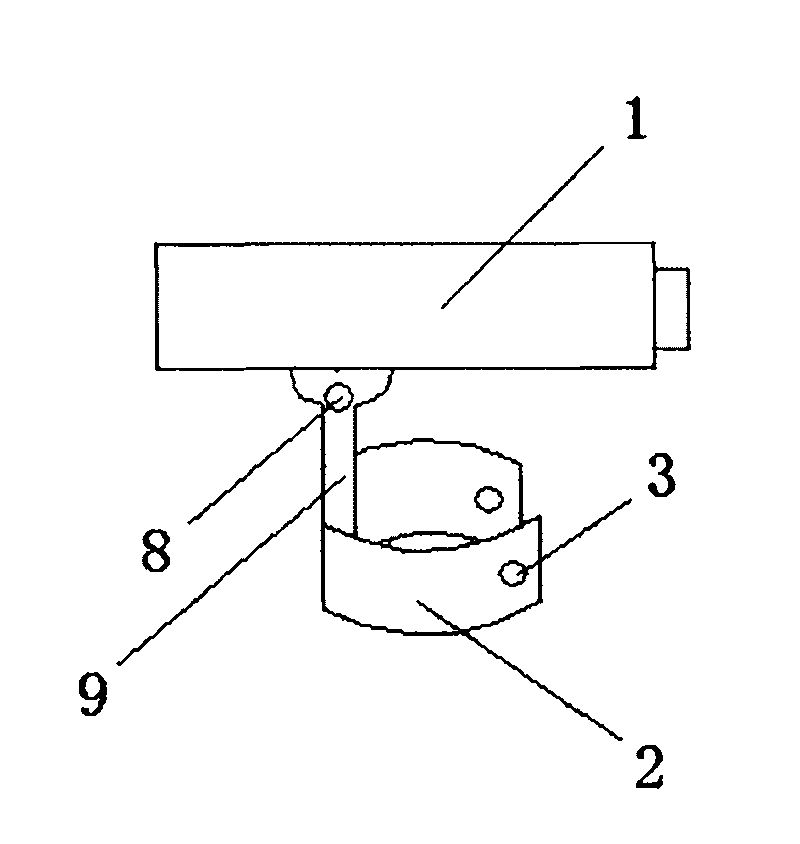

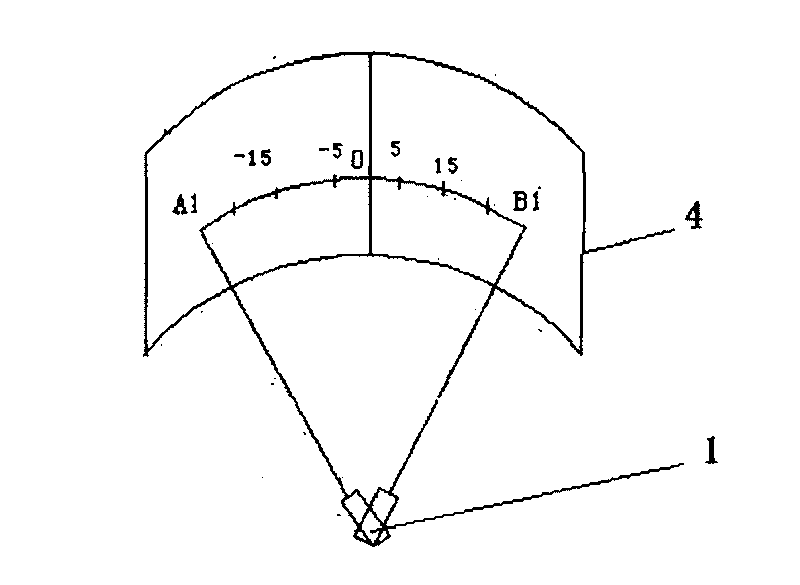

Windscreen wiper wiping angle measuring apparatus and measuring method thereof

ActiveCN101762246AEnsure irradiationIntuitive adjustmentUsing optical meansReciprocating motionLight beam

Owner:CHERY COMML VEHICLE ANHUI

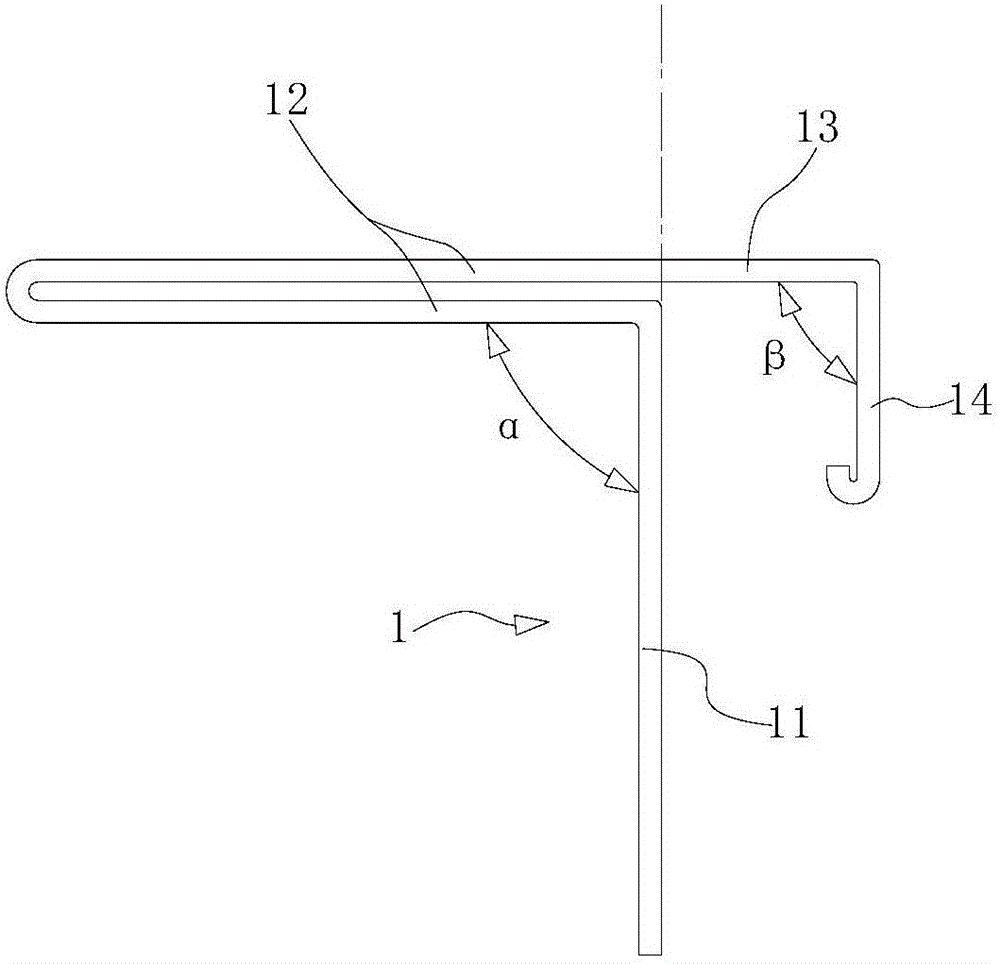

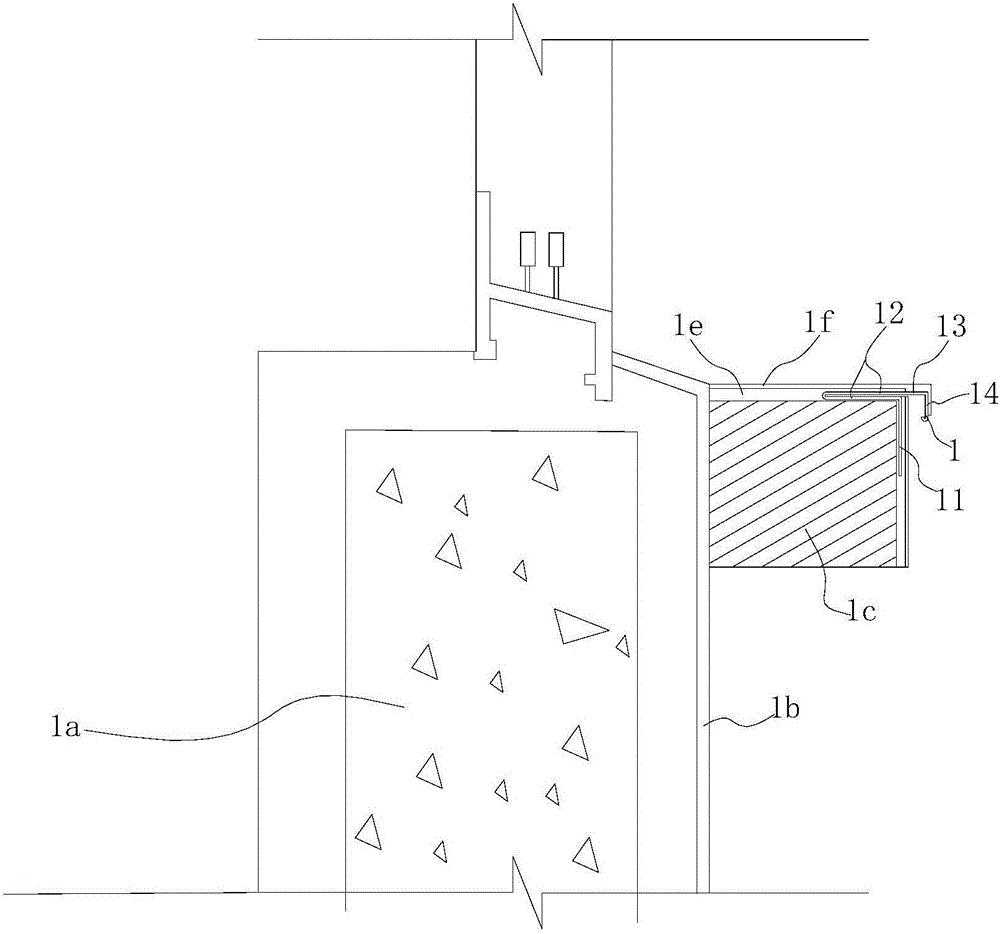

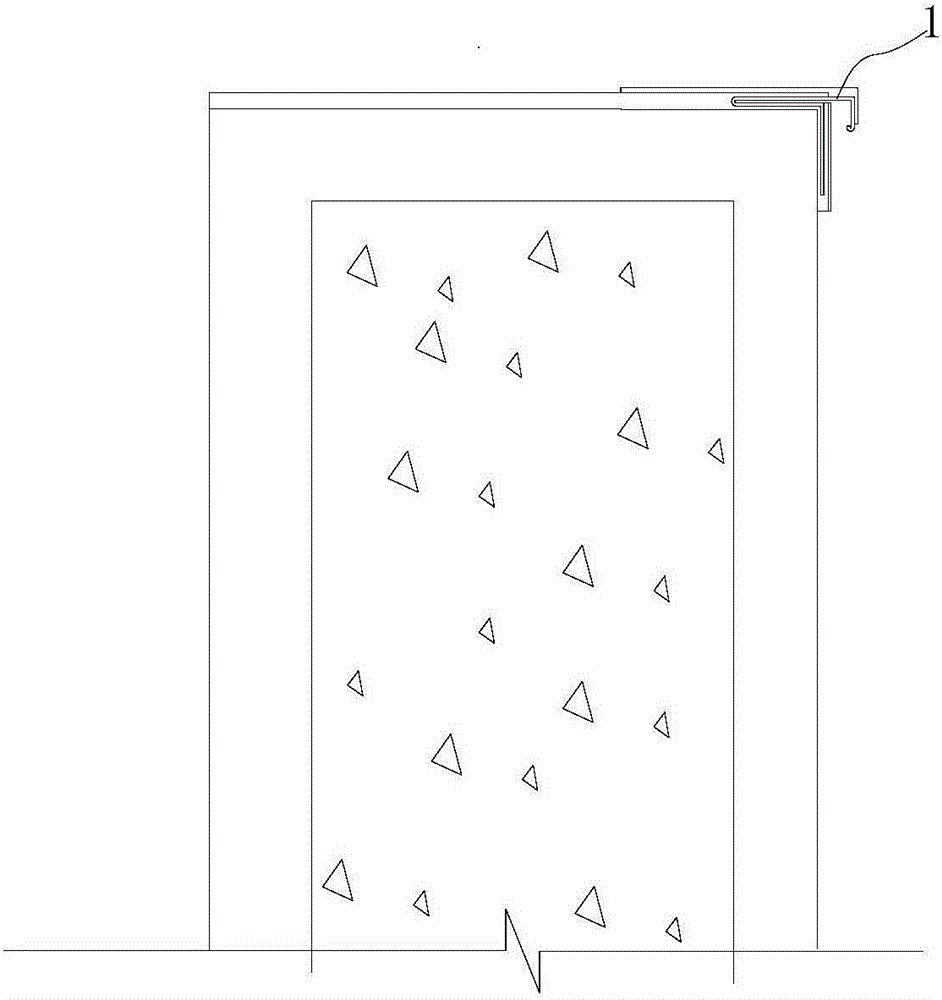

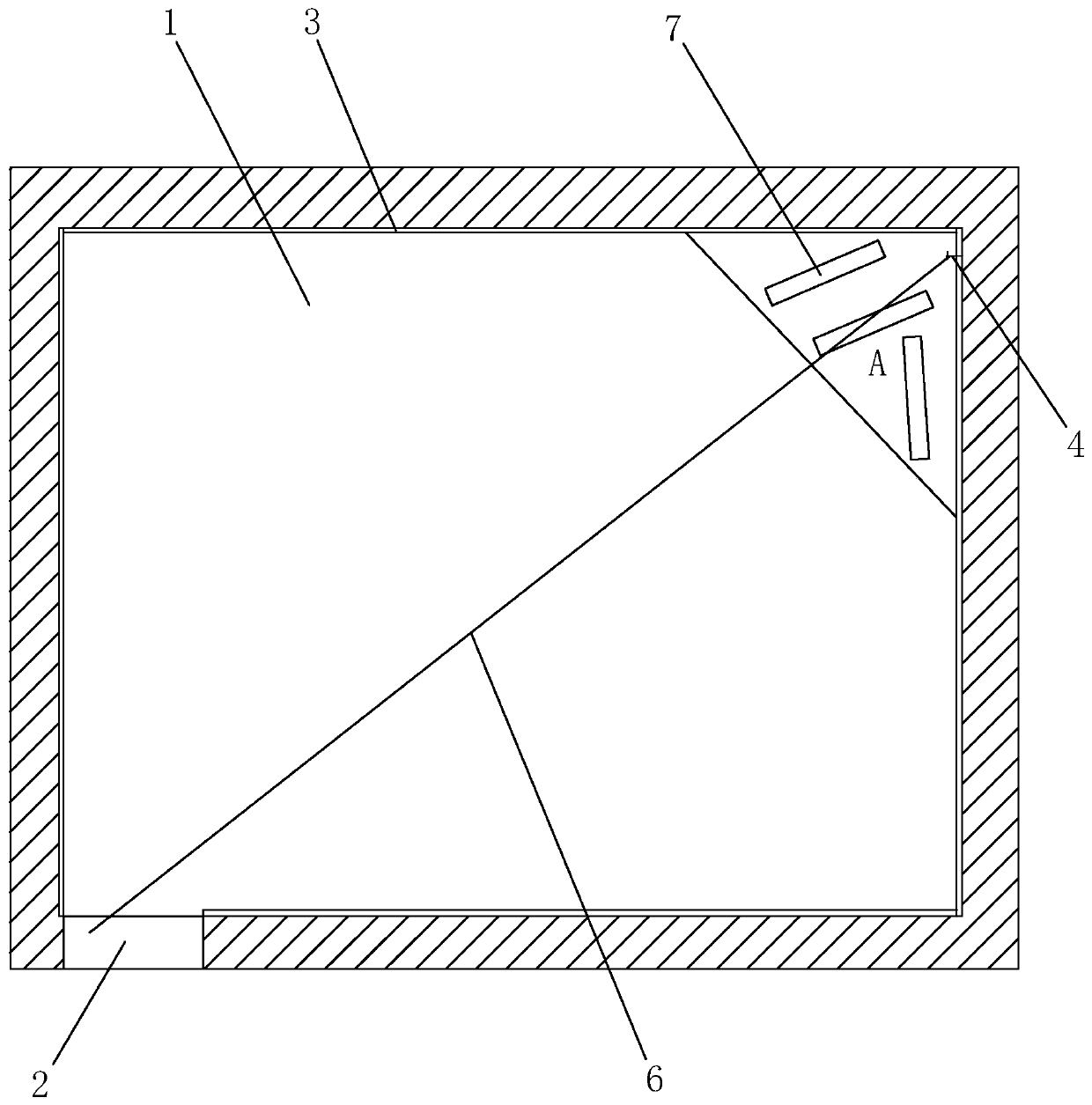

Metal water dripping line for preventing pollution of wall and wall bulging structure

InactiveCN106013631ARoof drainageExtreme positionLevel line

Owner:CHONGQING GESHANG BUILDING MATERIALS CO LTD

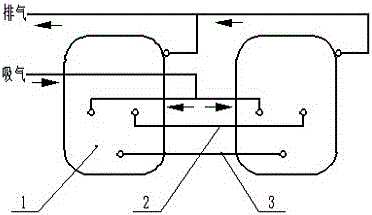

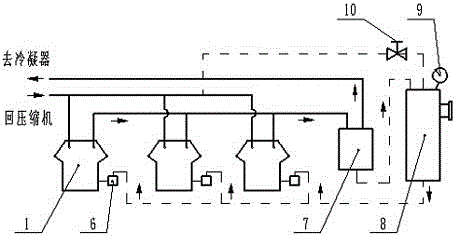

Oil returning system for multi-compressor parallel-connection unit

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

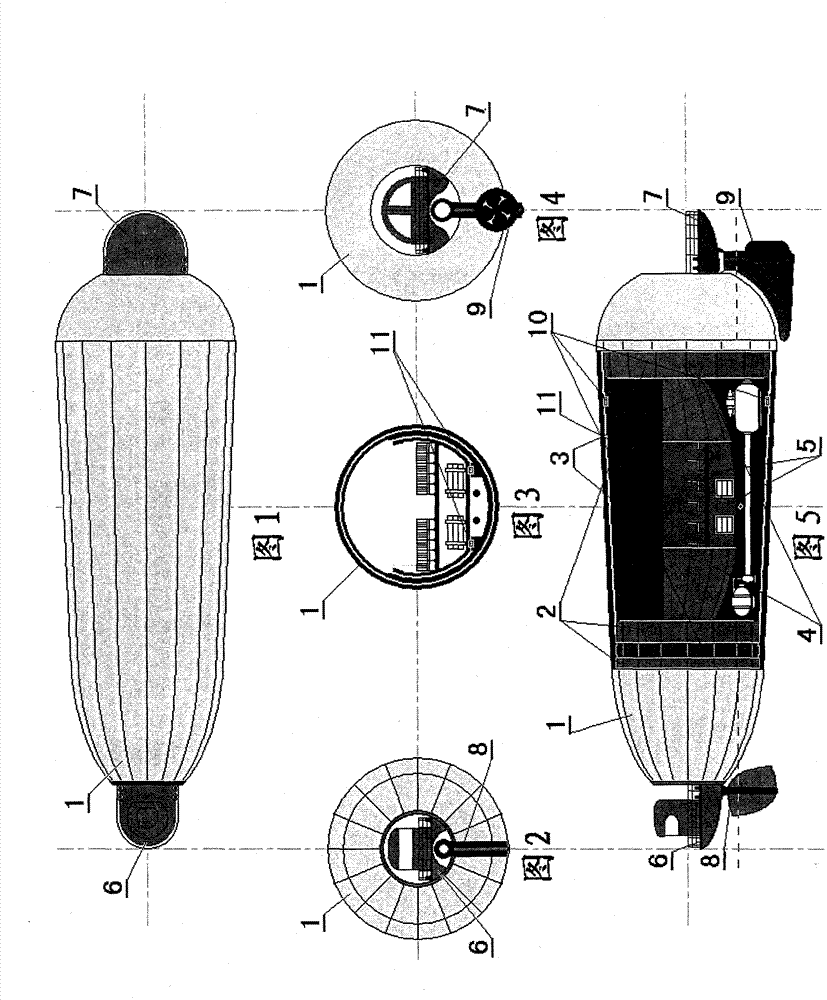

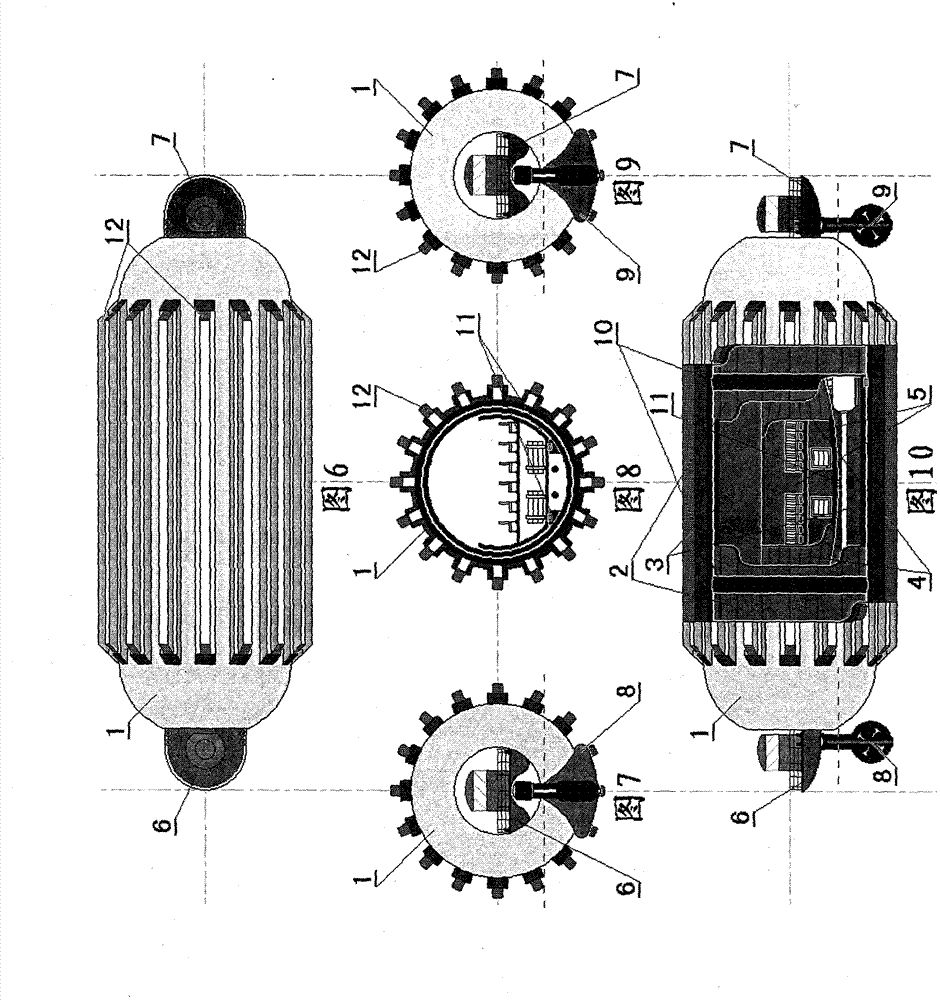

Drum-type ship

InactiveCN103359255AExtended navigable time slotsFlexible and diverse sailing methodsHull interior subdivisionHull shellsMarine engineeringLevel line

Owner:顾飞舟

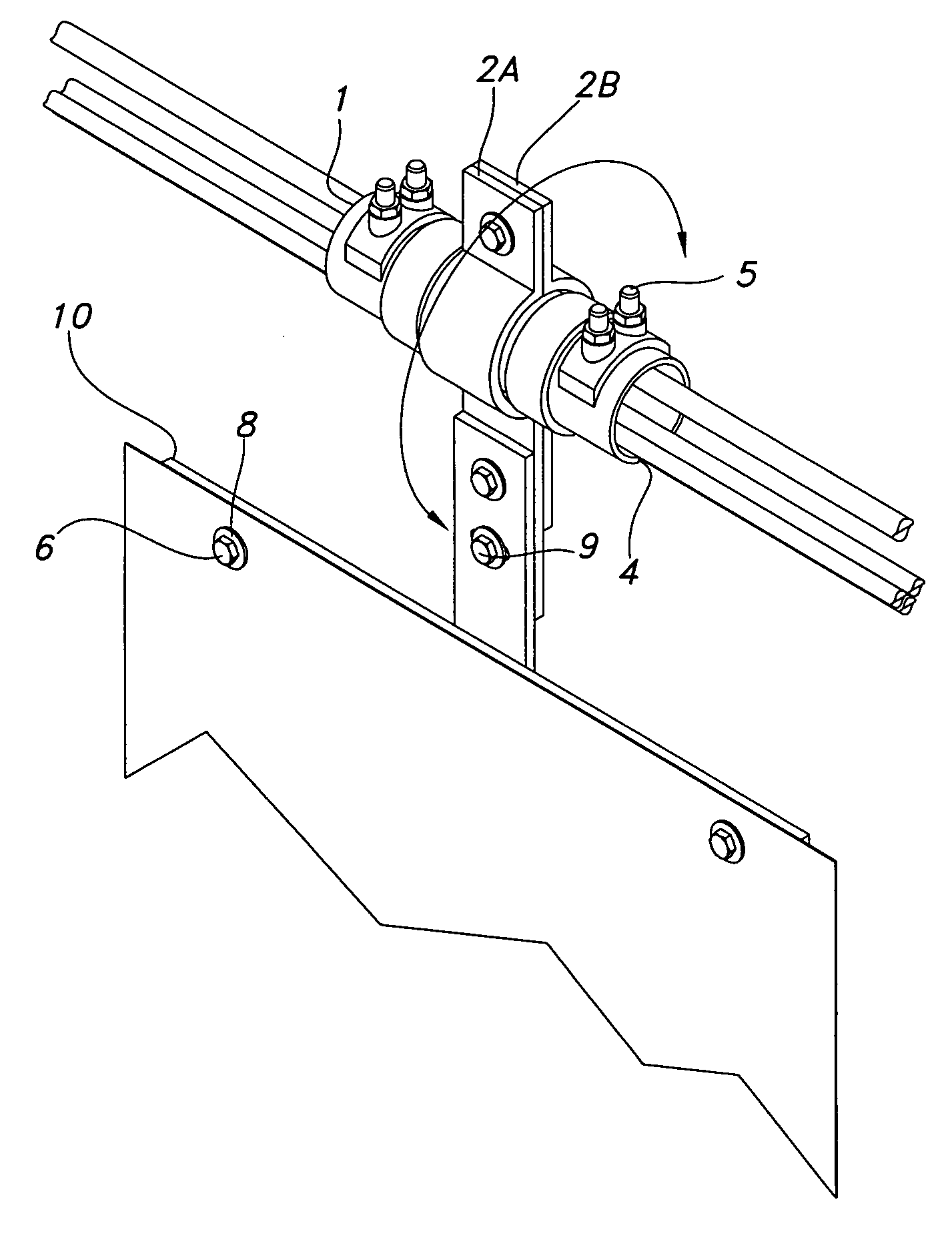

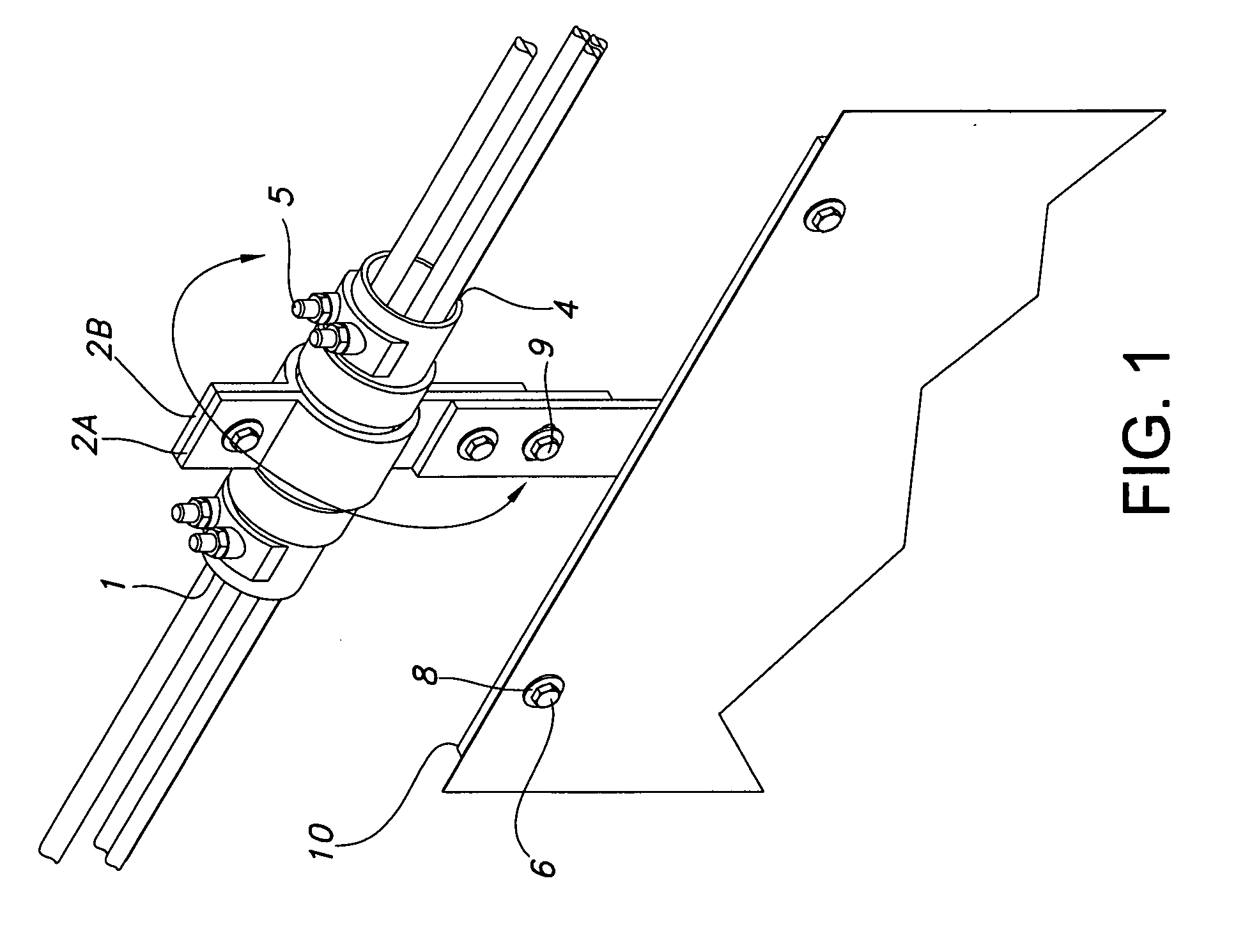

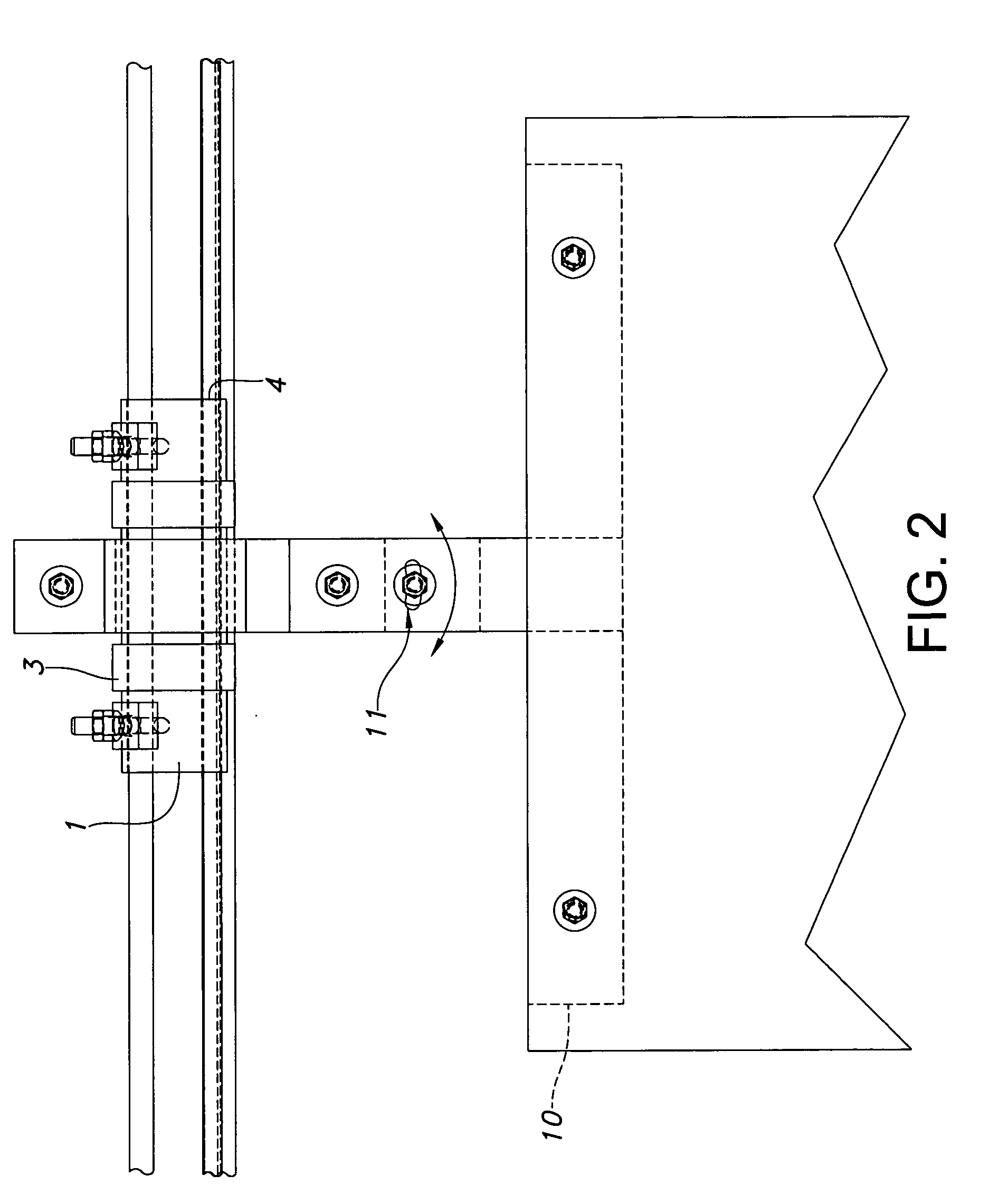

Orbital Sign Assembly

InactiveUS20090249667A1Reduce the possibilityCurtain suspension devicesStands/trestlesLevel lineMechanical engineering

Owner:MCCOY VANCE

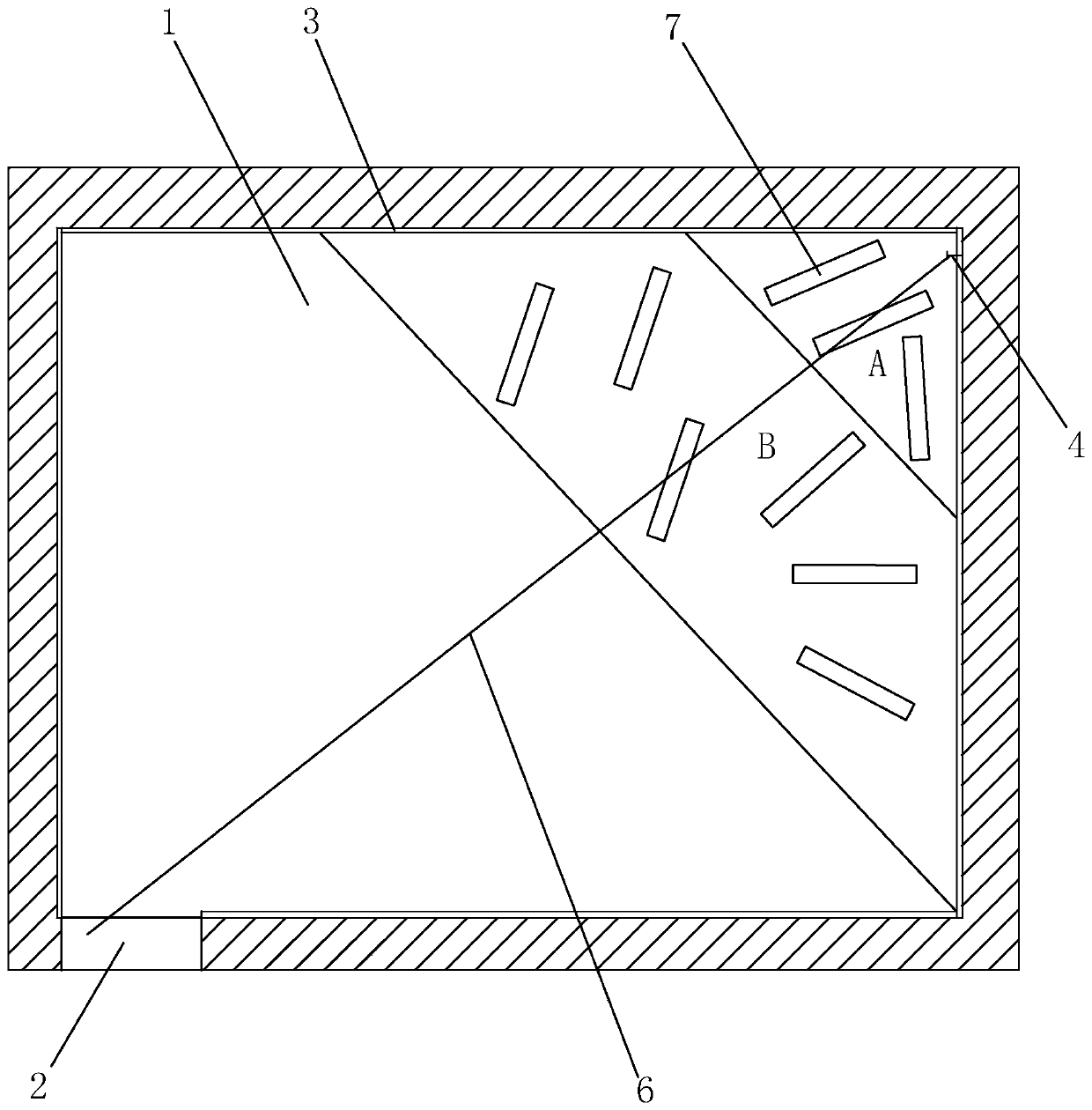

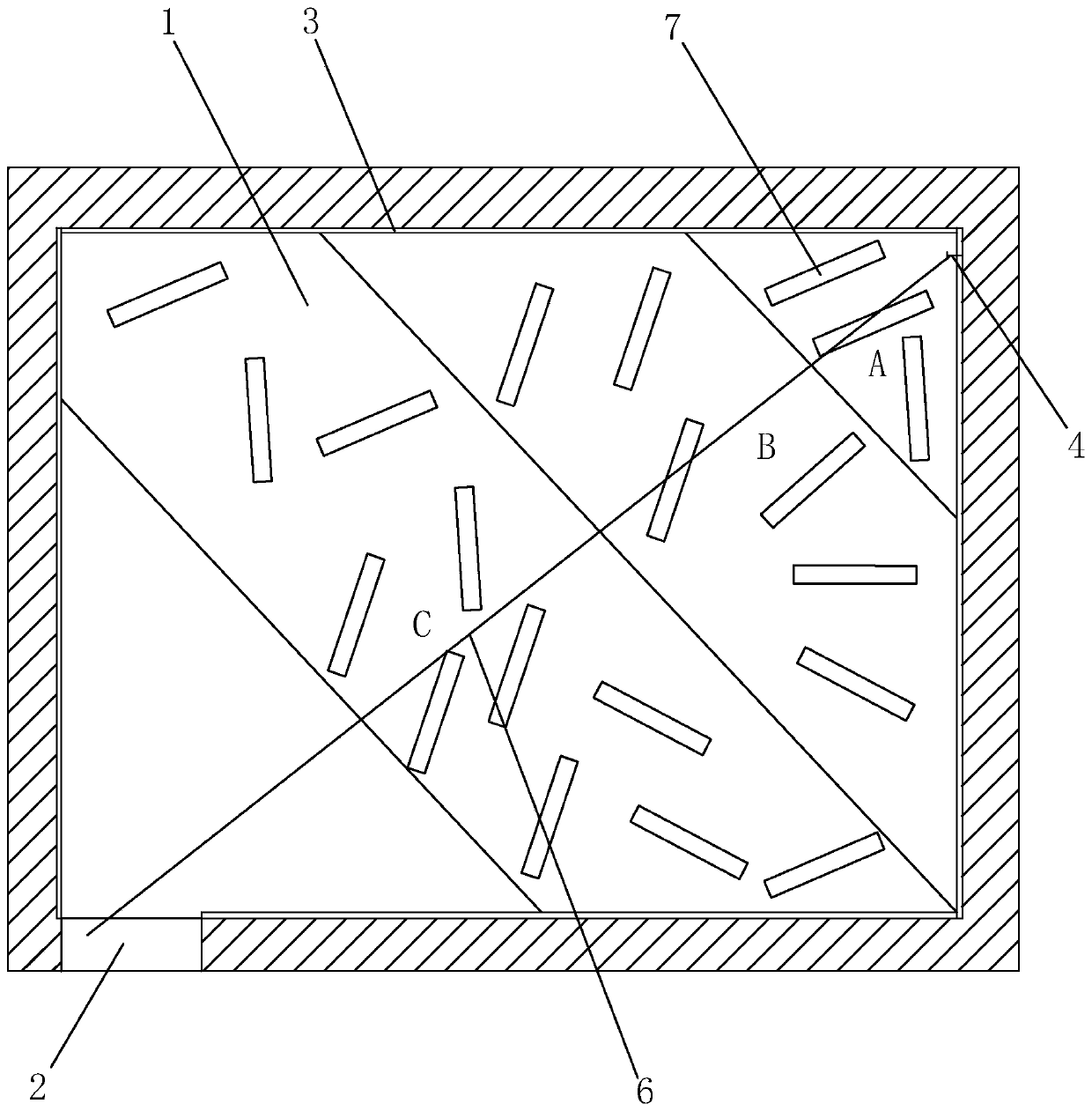

Ground fine leveling technology

Owner:江苏尚瑞鸿涛建设工程有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap