Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3 results about "Nitration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nitration is a general class of a chemical process for the introduction of a nitro group into an organic chemical compound. More loosely the term also is applied incorrectly to the different process of forming nitrate esters between alcohols and nitric acid, as occurs in the synthesis of nitroglycerin. The difference between the resulting structure of nitro compounds and nitrates is that the nitrogen atom in nitro compounds is directly bonded to a non-oxygen atom, typically carbon or another nitrogen atom, whereas in nitrate esters, also called organic nitrates, the nitrogen is bonded to an oxygen atom that in turn usually is bonded to a carbon atom (nitrito group).

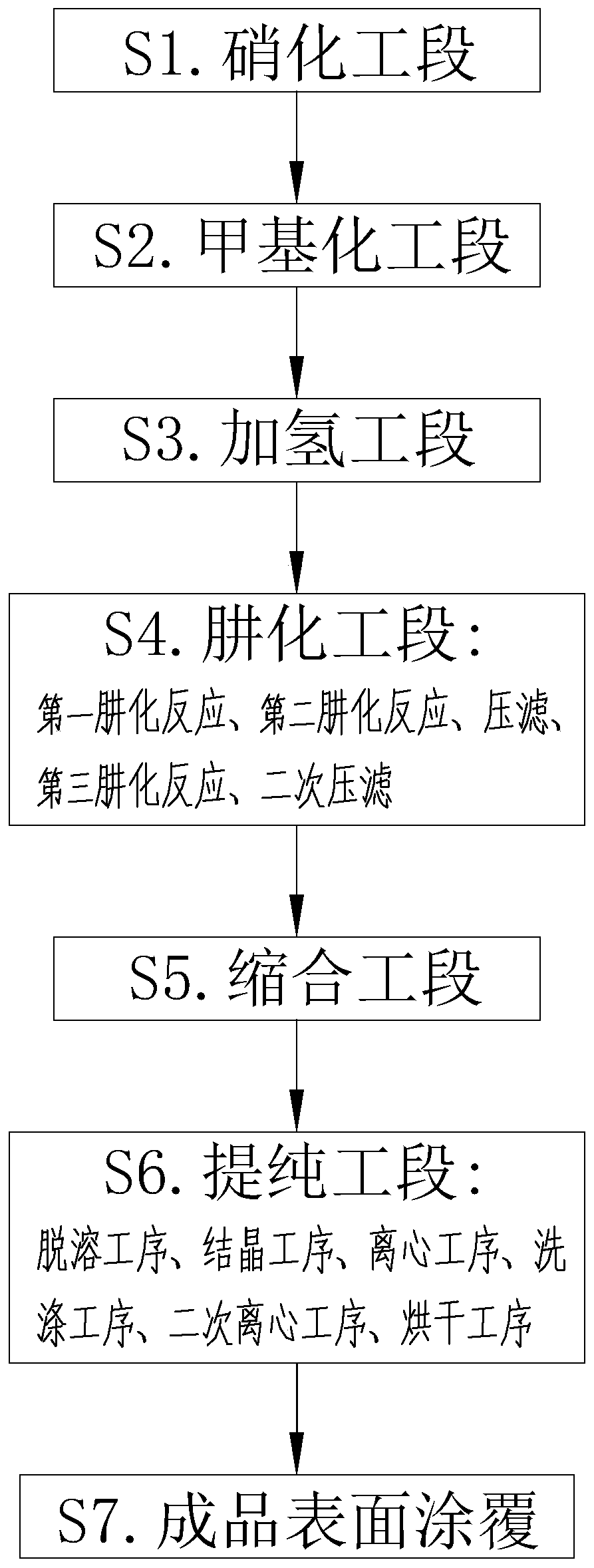

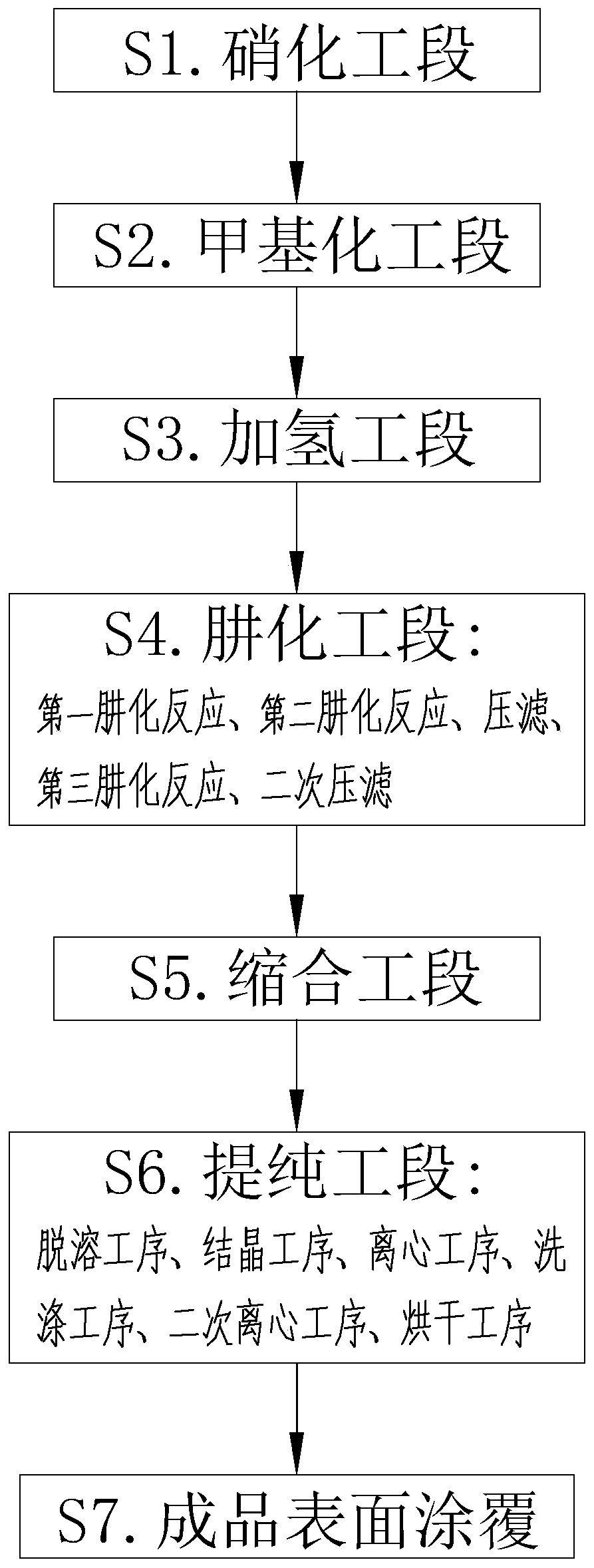

Synthetic method for bifenazate

Owner:绍兴上虞新银邦生化有限公司

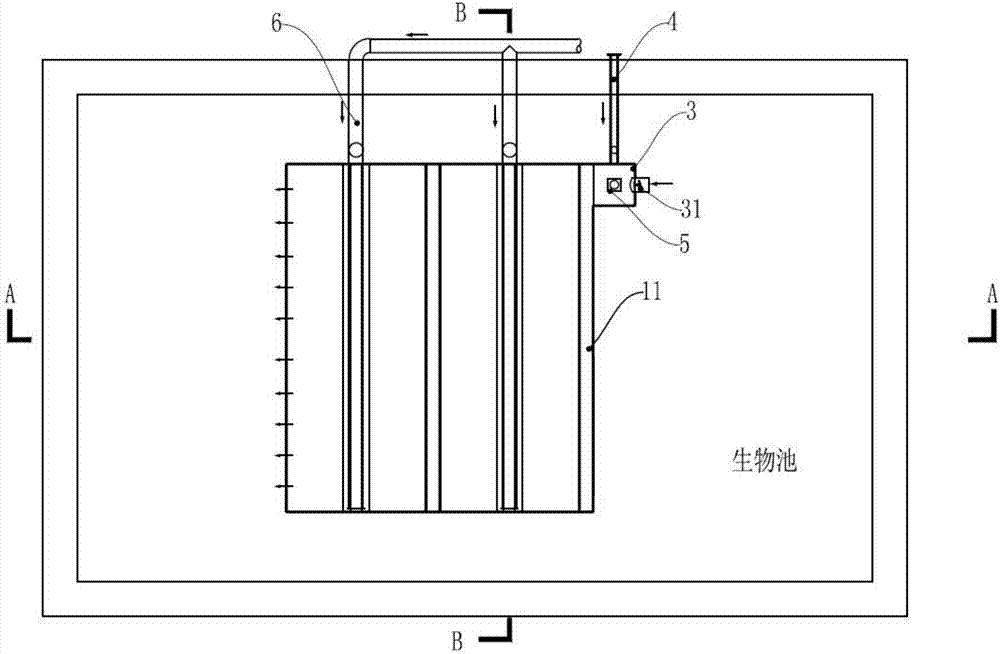

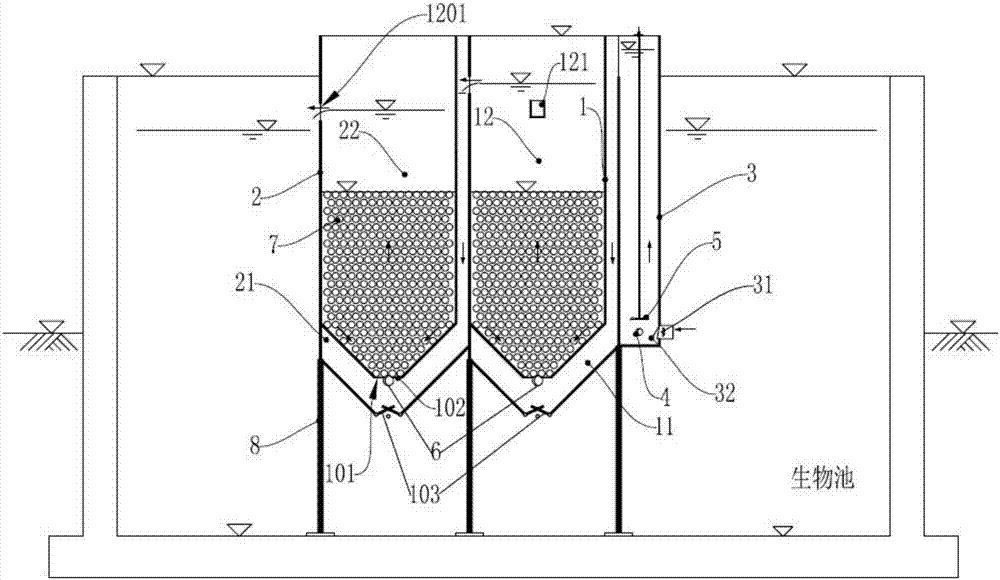

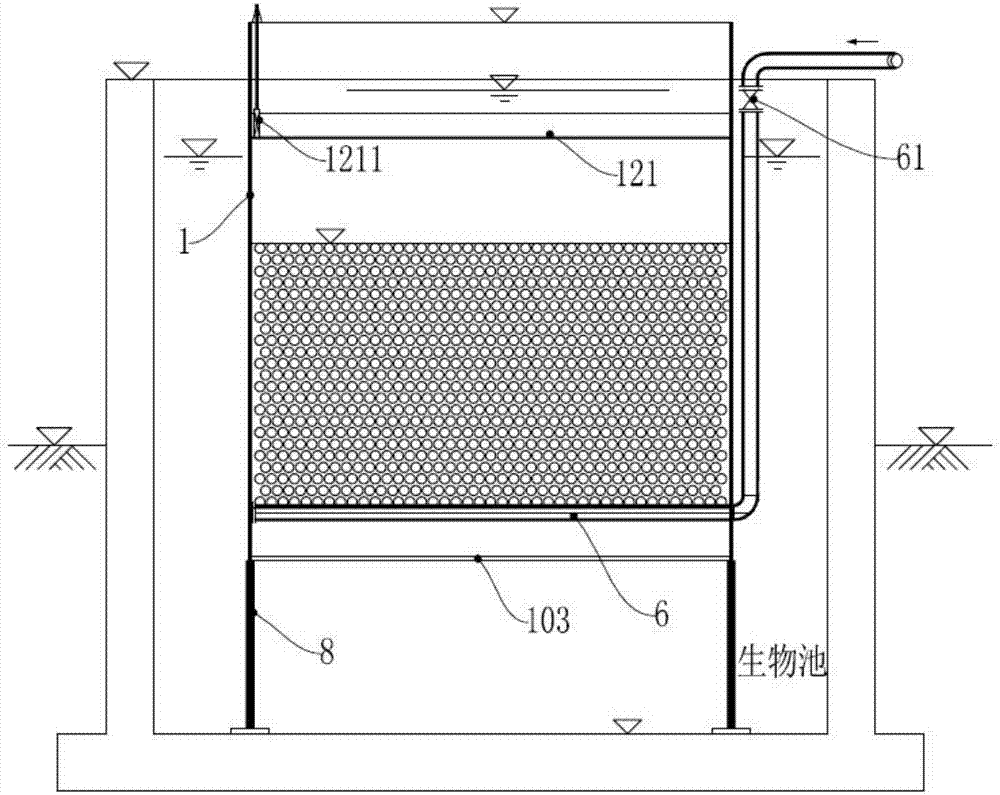

Synchronous denitrification reactor

PendingCN107473377AImprove denitrification efficiencyIncrease sludge concentrationTreatment with anaerobic digestion processesFirst-order reactionNitration

Owner:喻昌勇

Modification method for energy utilization of sludge or organic waste

ActiveCN105927986ASimple processLess investmentIncinerator apparatusCombustionHydrocotyle bowlesioides

Owner:湖南省小尹无忌环境能源科技开发有限公司 +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap