Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Saw dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soil improvement method for planting blueberries

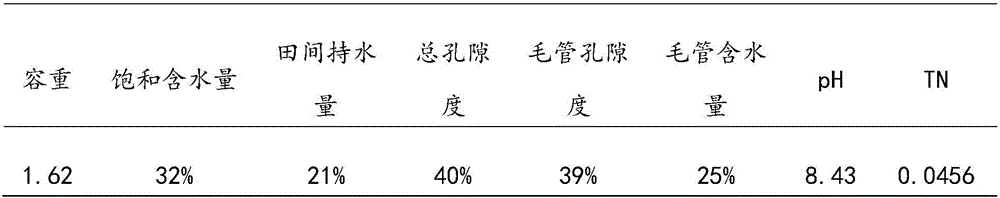

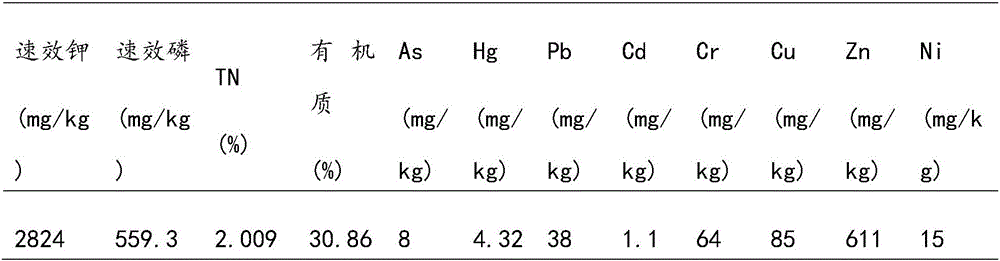

The invention relates to a soil improvement method, in particular to a soil improvement method for planting blueberries. The method mainly solves the technical problems that existing blueberry planting soil improvement measurements affect soil organism conditions, are high in cost and have toxic action on blueberry roots. The method includes the steps that firstly, fermented furfural residues are evenly applied to soil to be improved in summer, and turning plough is performed to make the fermented furfural residues and the soil fully mixed; secondly, after 1-1.5 months, peat, saw dust and organic fertilizer are applied to the soil, and turning plough is performed to make the peat, the saw dust and the organic fertilizer fully mixed with the soil; thirdly, manual weeding is performed; fourthly, soil plowing and ridging are performed in the spring of the next year, and the improvement to the soil for planting blueberries is completed. The pH value of the improved soil is 4.5-4.8, nutrient status of the soil is improved, and the survival rate of transplanted biennial blueberries and the survival rate of six-year-growing-period blueberries can reach 95-96% and 96-97% respectively. The method is used for blueberry cultivation.

Owner:JILIN NORMAL UNIV

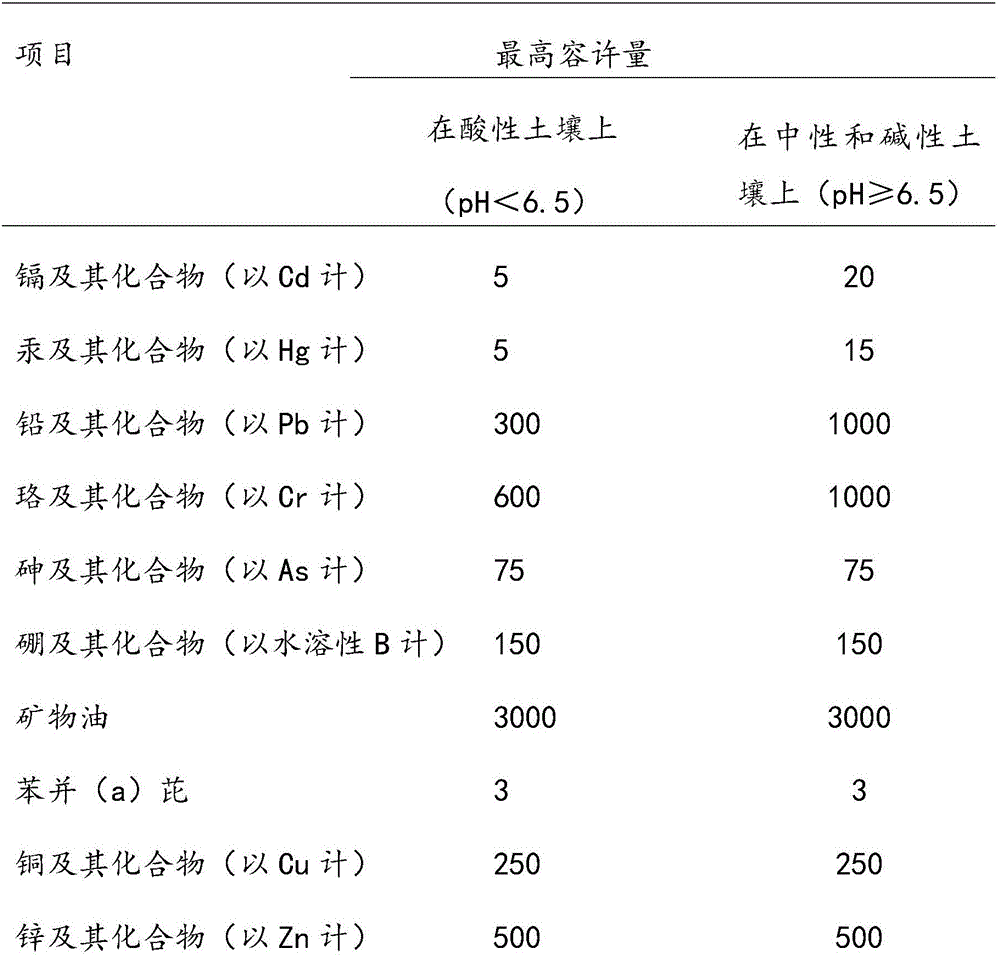

External-soil spray seeding matrix and preparation method thereof

InactiveCN105900729AFertilizer effect time is longEnvironmental protection and low priceGrowth substratesCulture mediaSludge compostResource utilization

Owner:BEIJING FORESTRY UNIVERSITY

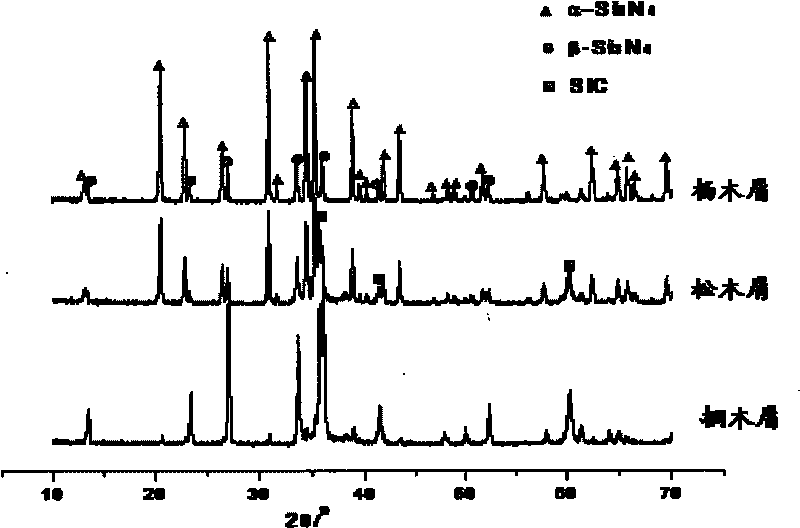

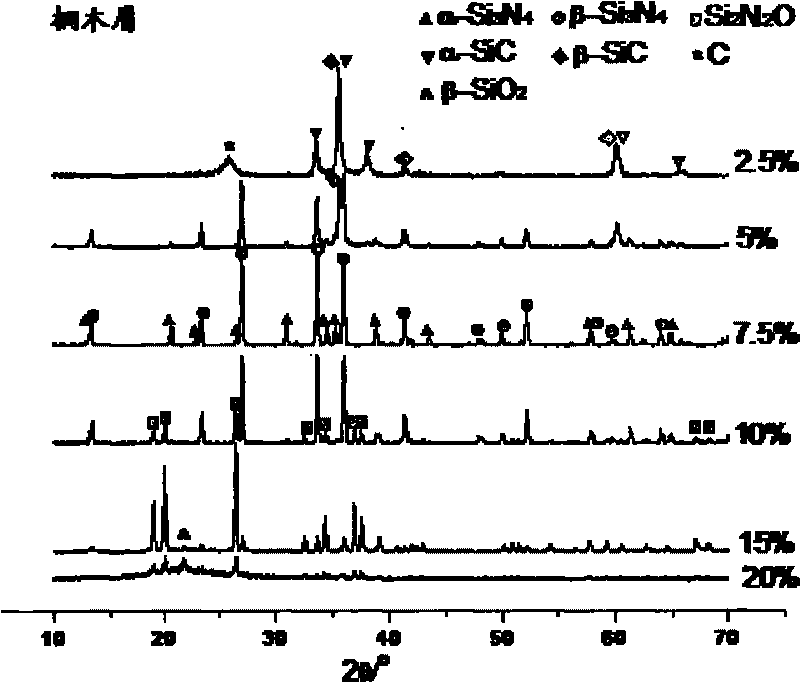

Method for preparing silicon nitride powder with saw dust

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for manufacturing polyurethane flexible foam packing plates

InactiveCN103786231AHigh bonding strengthIncrease elasticityPolyureas/polyurethane adhesivesWood working apparatusPolyurethane adhesiveSingle plate

Owner:孟可星

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap