Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3 results about "Static mixer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

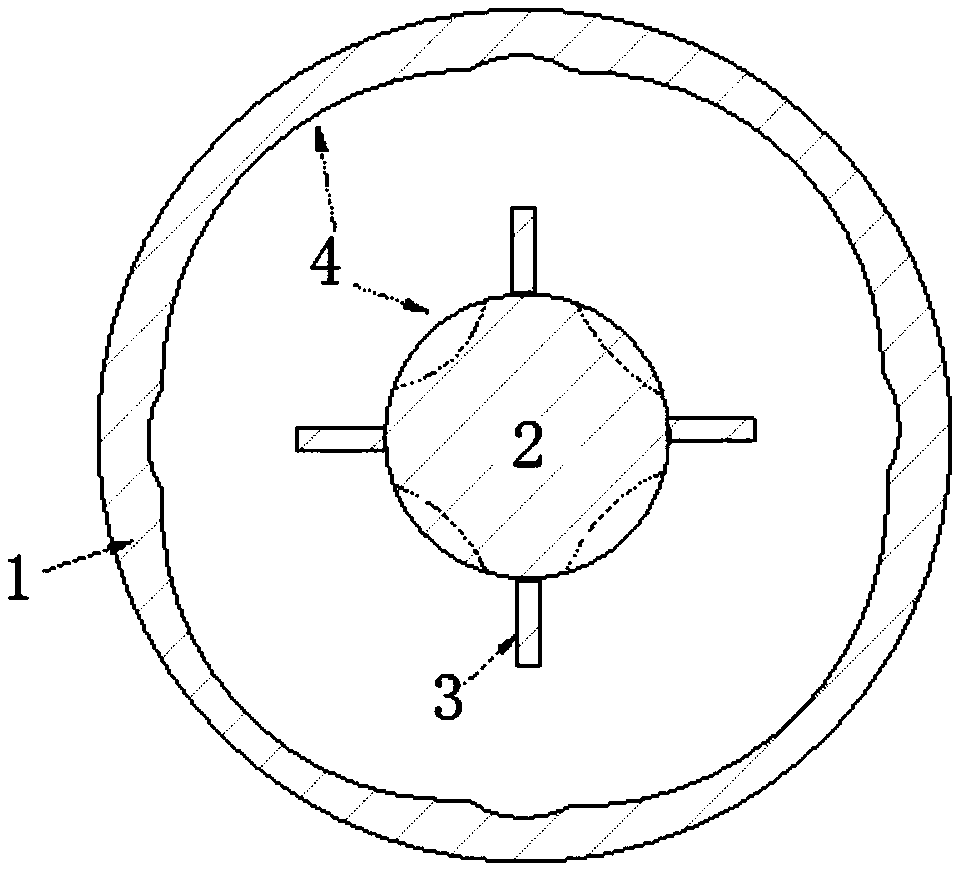

A static mixer is a precision engineered device for the continuous mixing of fluid materials, without moving components. Normally the fluids to be mixed are liquid, but static mixers can also be used to mix gas streams, disperse gas into liquid or blend immiscible liquids. The energy needed for mixing comes from a loss in pressure as fluids flow through the static mixer. One design of static mixer is the plate-type mixer and another common device type consists of mixer elements contained in a cylindrical (tube) or squared housing. Mixer size can vary from about 6 mm to 6 meters diameter. Typical construction materials for static mixer components included stainless steel, polypropylene, Teflon, PVDF, PVC, CPVC and polyacetal. The latest design involve static mixing elements made of glass-lined steel.

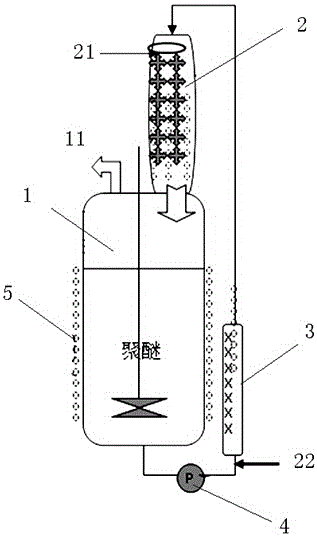

Method for removing low-boiling-point substance in polyether

ActiveCN105037704AMeet production requirementsHigh removal efficiency of low boilersBoiling pointNitrogen

Owner:JURONG NINGWU NEW MATERIAL CO LTD BY SHARES

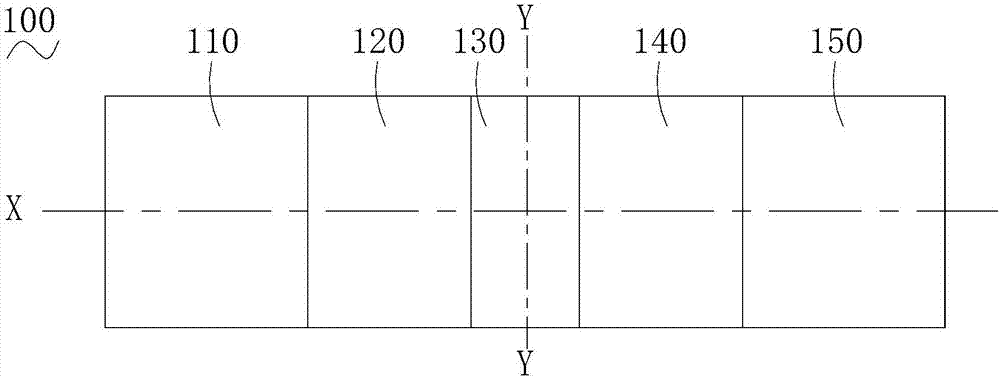

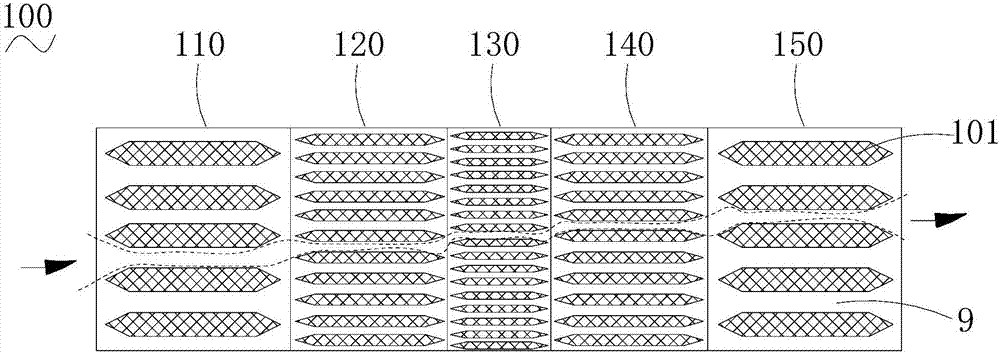

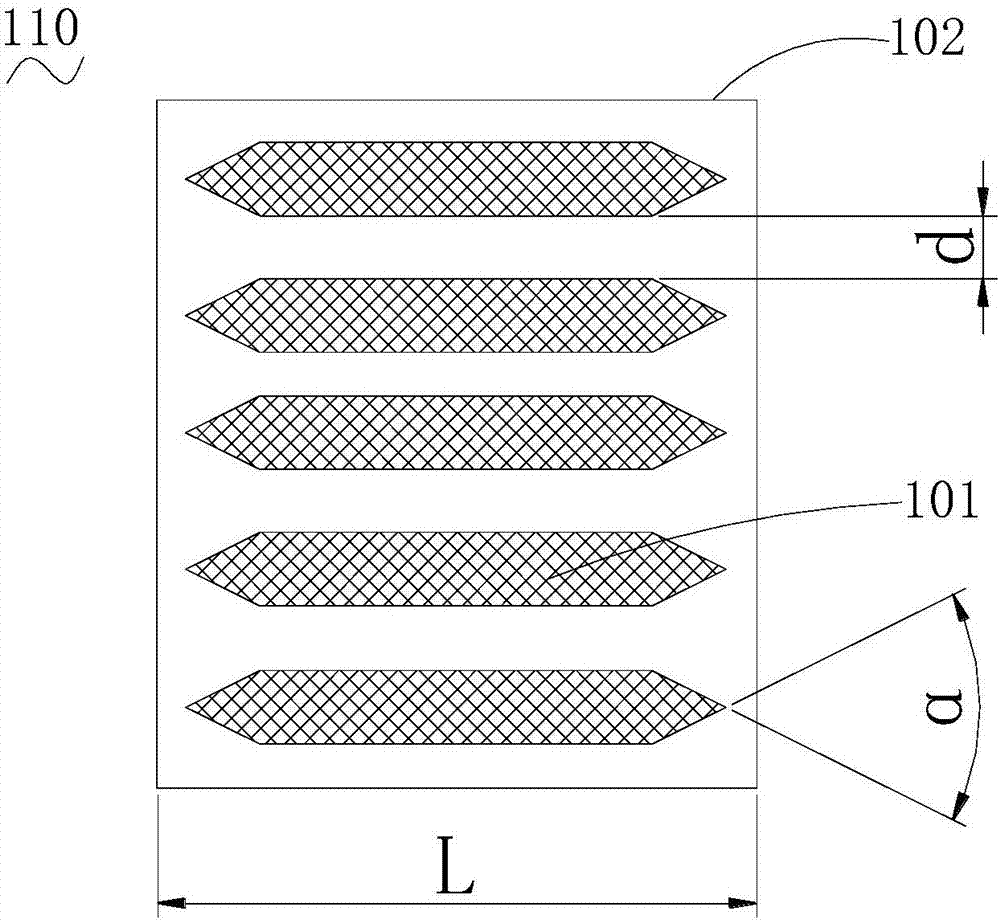

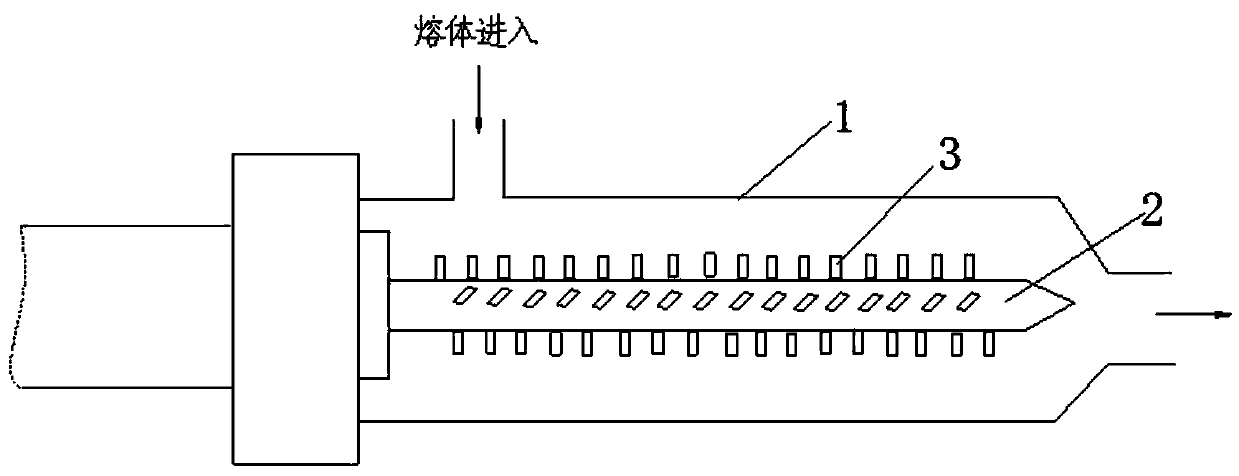

Static mixer and mixing device

Owner:SUZHOU NAPO ADVANCED MATERIAL TECH CO LTD

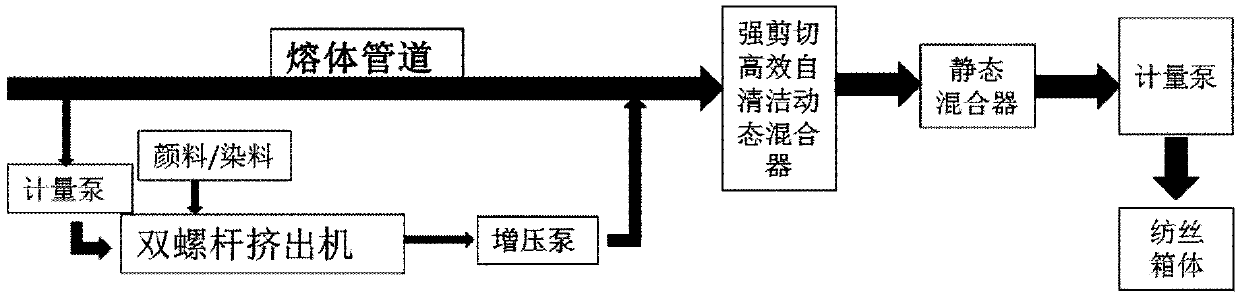

Direct-spun polyester colored staple fiber production equipment and direct-spun polyester colored staple fiber production method

InactiveCN111041564AEvenly dispersedRealize online direct spinningPigment addition to spinning solutionMonocomponent polyesters artificial filamentPolyesterFiber

Owner:CHINA PETROLEUM & CHEM CORP +1

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap