Method for producing safe farm products in organic polluted soil

A technology for organic pollution and agricultural products, applied in the field of production of safe agricultural products, can solve problems such as unapplied safe agricultural products, and achieve the effects of easy acquisition, significant decline and obvious effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

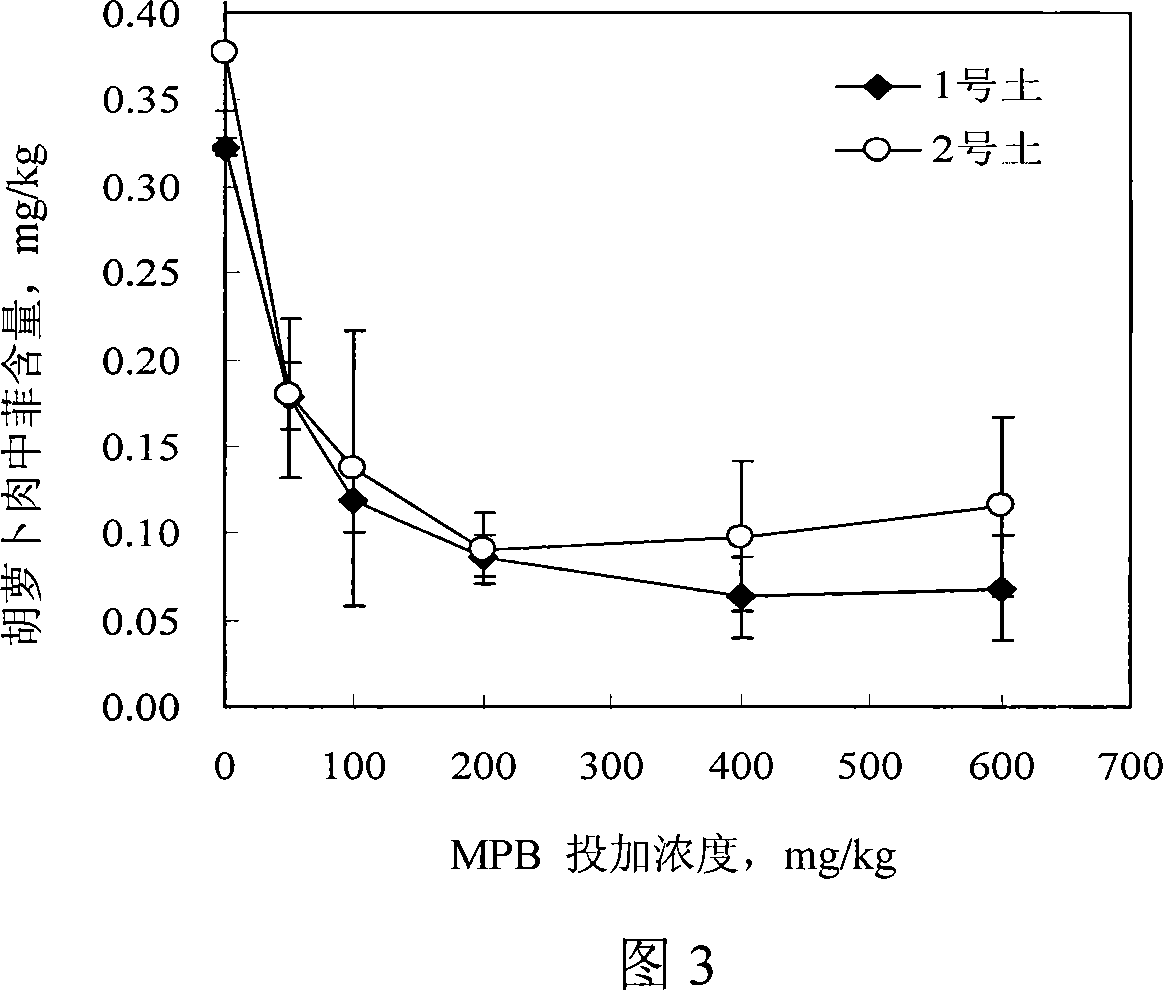

[0017] Add 50 mg / kg myristylpyridinium bromide (MPB) to PAHs polluted (50 mg / kg phenanthrene concentration) soil to produce carrots.

[0018] 25 mg of tetradecylpyridinium bromide was dissolved in 50 mL of water, and the solution was added to 500 g of soil in a pot. At the same time, a blank control without adding tetradecylpyridinium bromide was set.

[0019] Sprinkle the carrot seeds directly into the pot and thin the seedlings after germination. Carrots were cultivated in a greenhouse at 25°C for 100 days according to conventional water and fertilizer management procedures, and carrots were harvested.

[0020] The collected carrot samples were dried by a freeze dryer, ultrasonically extracted with a mixture of dichloromethane and acetone (volume ratio 1:1), concentrated and purified by rotary evaporation, rinsing through a silica gel column, etc., constant volume with methanol, and finally passed through 0.22 μm filter and analyzed by HPLC.

[0021] The results showed t

Embodiment 2

[0023] Add 200mg / kg myristylpyridinium bromide (MPB) to PAHs polluted (50mg / kg phenanthrene concentration) soil to produce carrots.

[0024] 100 mg of tetradecylpyridinium bromide was dissolved in 50 mL of water, and the solution was added to 500 g of soil in a pot. At the same time, a blank control without adding tetradecylpyridinium bromide was set.

[0025] Sprinkle the carrot seeds directly into the pot and thin the seedlings after germination. Carrots were cultivated in a greenhouse at 25°C for 100 days according to conventional water and fertilizer management procedures, and carrots were harvested.

[0026] The collected carrot samples were dried by a freeze dryer, ultrasonically extracted with a mixture of dichloromethane and acetone (volume ratio 1:1), concentrated and purified by rotary evaporation, rinsing through a silica gel column, etc., constant volume with methanol, and finally passed through 0.22 μm filter and analyzed by HPLC.

[0027] The results showed t

Embodiment 3

[0029] Add 600mg / kg myristylpyridinium bromide (MPB) to PAHs polluted (50mg / kg phenanthrene concentration) soil to produce carrots.

[0030] 300 mg of tetradecylpyridinium bromide was dissolved in 50 mL of water, and the solution was added to 500 g of soil in a pot. At the same time, a blank control without adding tetradecylpyridinium bromide was set.

[0031] Sprinkle the carrot seeds directly into the pot and thin the seedlings after germination. Carrots were cultivated in a greenhouse at 25°C for 100 days according to conventional water and fertilizer management procedures, and carrots were harvested.

[0032] The collected carrot samples were dried by a freeze dryer, ultrasonically extracted with a mixture of dichloromethane and acetone (volume ratio 1:1), concentrated and purified by rotary evaporation, rinsing through a silica gel column, etc., constant volume with methanol, and finally passed through 0.22 μm filter and analyzed by HPLC.

[0033] The results showed t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap