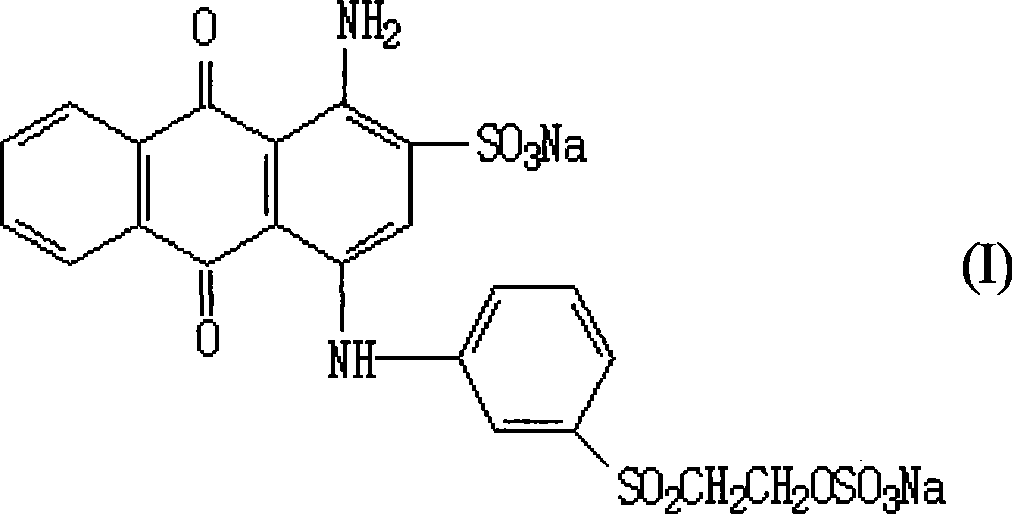

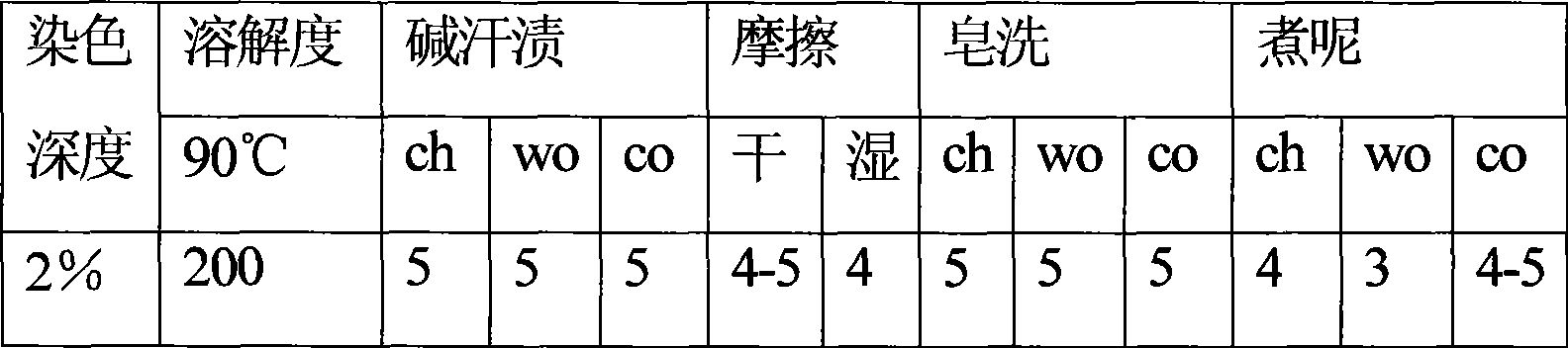

Preparation of brilliant blue KN-R

A technology of reactive dyes and meta-oils for wool, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of clogging the filter screen and high filtration temperature, and achieve the prevention of sulfate group hydrolysis and high efficiency. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] 1. Ingredients list:

[0012] raw material name molecular weight molecular ratio Percent consumption (Kg) Feeding amount (mole) bromide 404 1.0 80.8 0.2 meta oil 201 1.2 48.2 0.24 sodium bicarbonate 84 4.0 67.2 0.8 Cuprous chloride 199 0.05 1.99 0.01 Electrolytic copper powder 64 0.15 0.4 0.0063 sulfuric acid 98 40.8 800 8.16 DMF (Dimethylformamide) 1.2

[0013] 2, dyestuff preparation technology of the present invention operates as follows:

[0014] (a) Condensation: Dissolution of bromaline and meta-oil: add 200ml of bottom water to a four-neck bottle, add 80.8g of bromaline and 48.2g of meta-oil, raise the temperature, control the temperature to 95°C, and dissolve all the materials , keep warm for 10 minutes, lower the temperature to 80°C to obtain a mixed solution; dissolve 1.99g of cuprous oxide in 1.2g of DMF, then add it and 0.4g of electrolytic copper powder into the above mixed

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap