Blade lock

A blade lock and blade technology, applied in the field of blade locks, can solve the problems of poor anti-theft performance, decreased security, unstable performance, etc., and achieve the effects of improving safety and anti-theft performance, easy to manufacture and use, and strong anti-theft performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

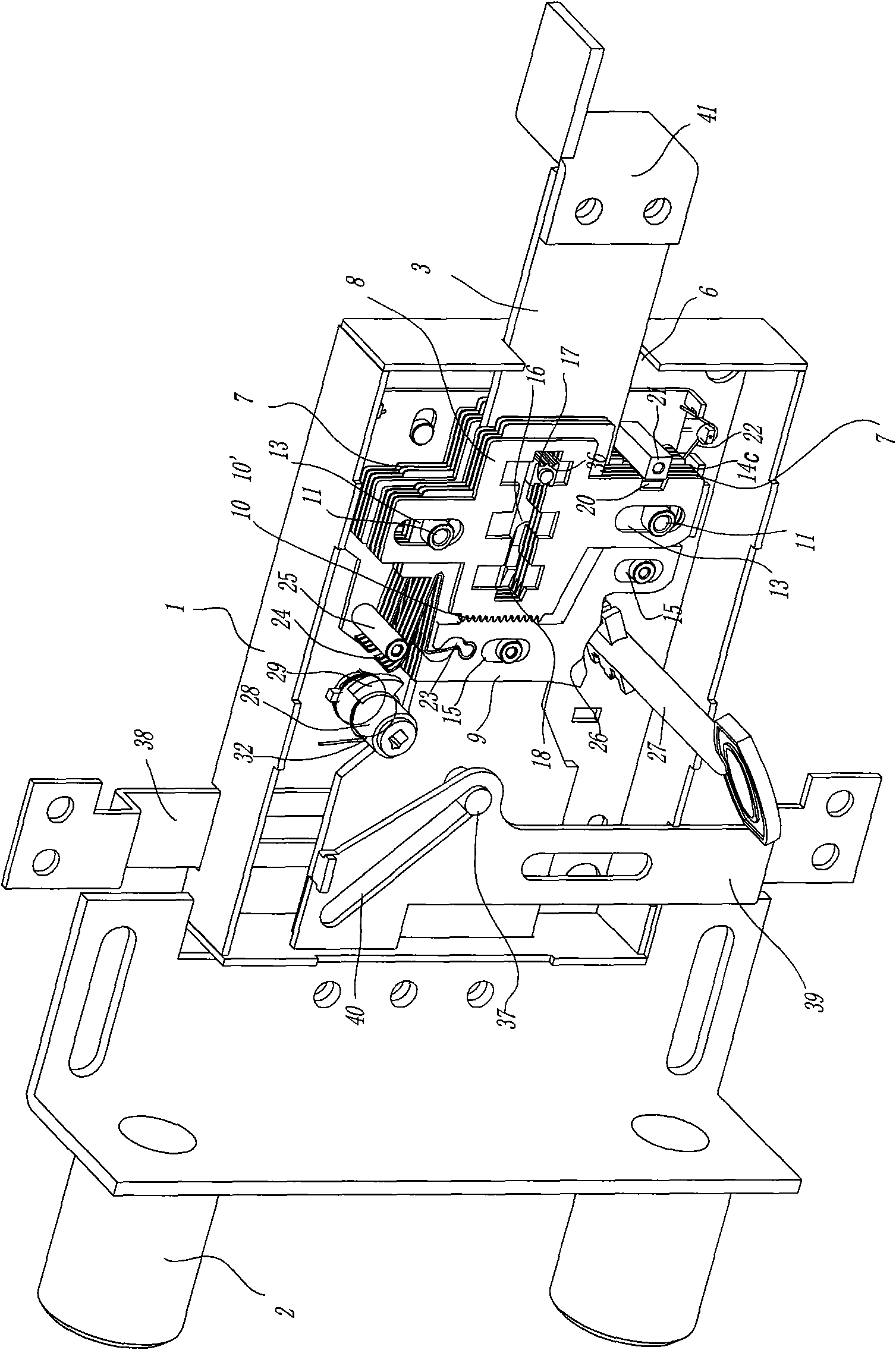

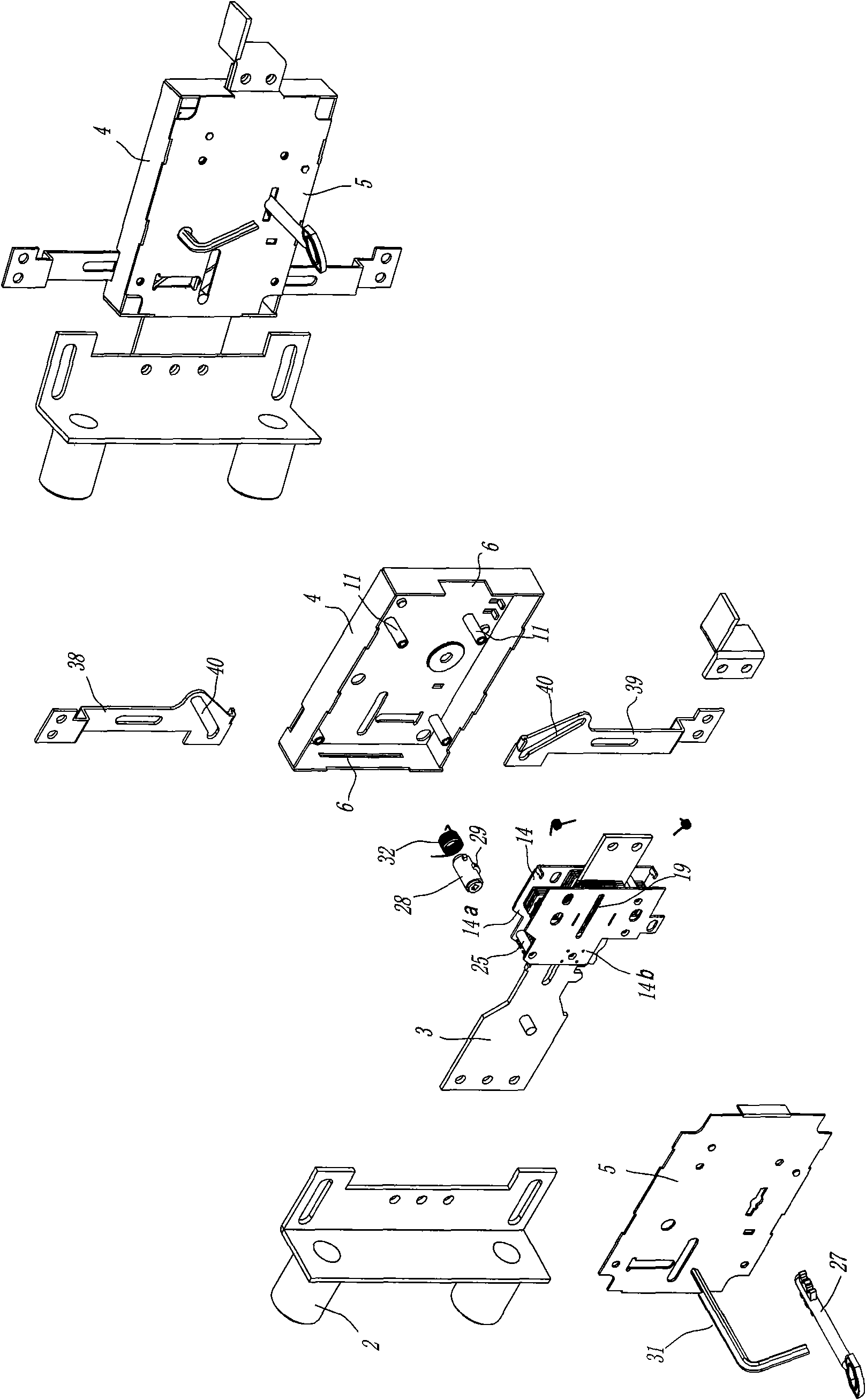

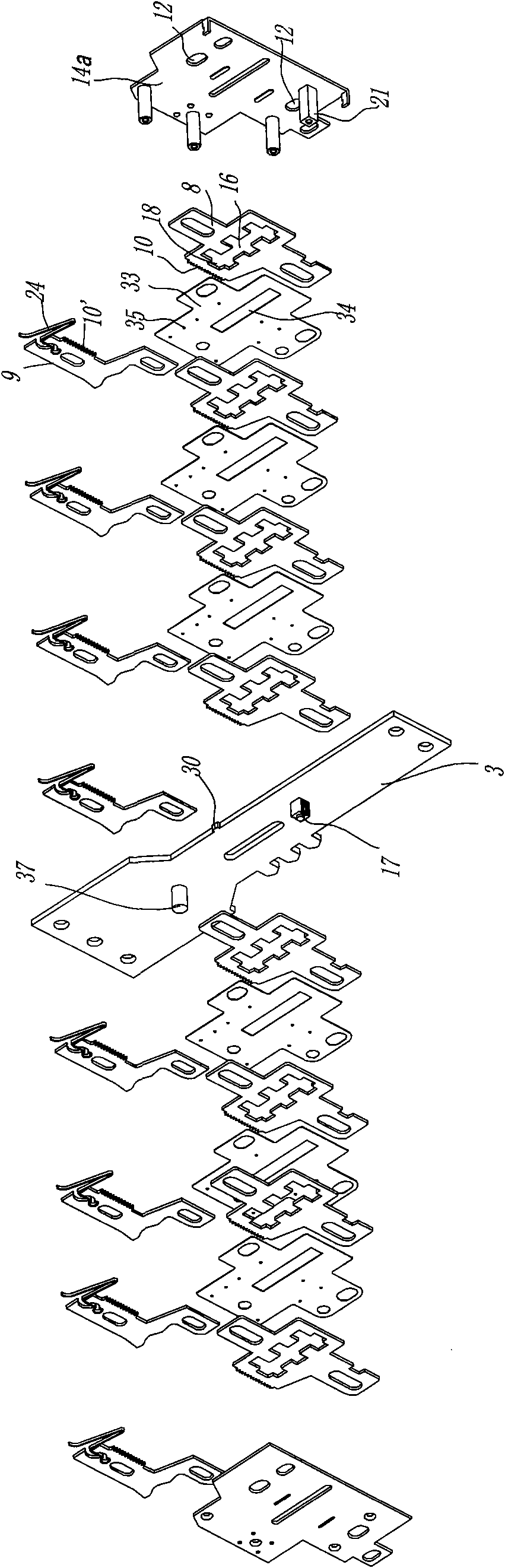

[0023] As shown in the figure, a kind of blade lock includes a lock shell 1, a lock tongue 2 and a lock tongue drag plate 3 connected with the lock tongue, wherein the lock shell 1 is divided into a lock shell base 4 and a lock cover 5, which are connected by screws. After the lock case 1 is installed, the left and right sides of the lock case 1 (as shown in the figure) are provided with openings 6, so that the lock tongue extension plate 3 is limited in the opening of the lock case 1 and can be moved laterally. There are blade groups 7 stacked on the sides. In this embodiment, a blade group 7 is stacked on each of the two sides of the lock tongue carriage 3. Each blade group 7 includes several blades, and the blades are divided into variable blades 8 and variable blades. There are two kinds of tooth pieces 9. The variable blade 8 is provided wi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap