Method for preparing anionic colorimetric sensing cellulosic material

A colorimetric sensing, cellulose technology, applied in fiber processing, plant fiber, analysis by chemical reaction of materials, etc. Simple, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

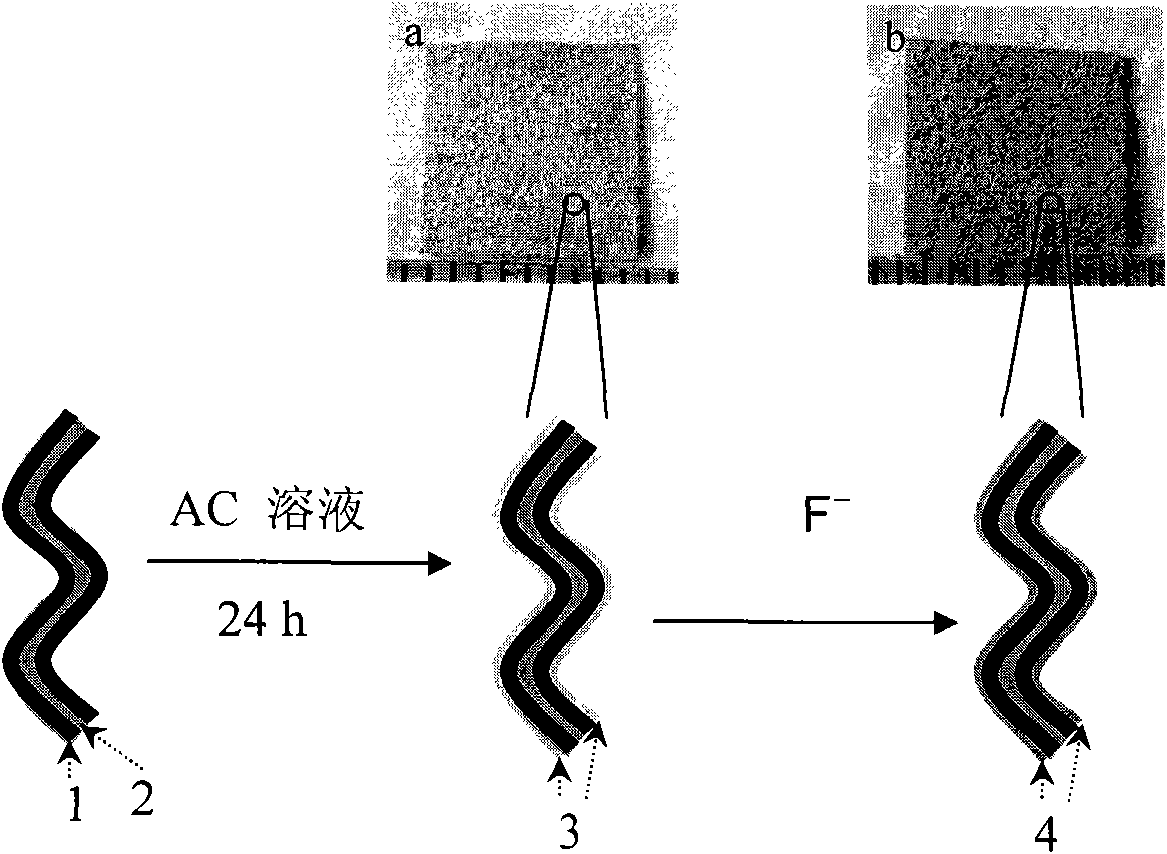

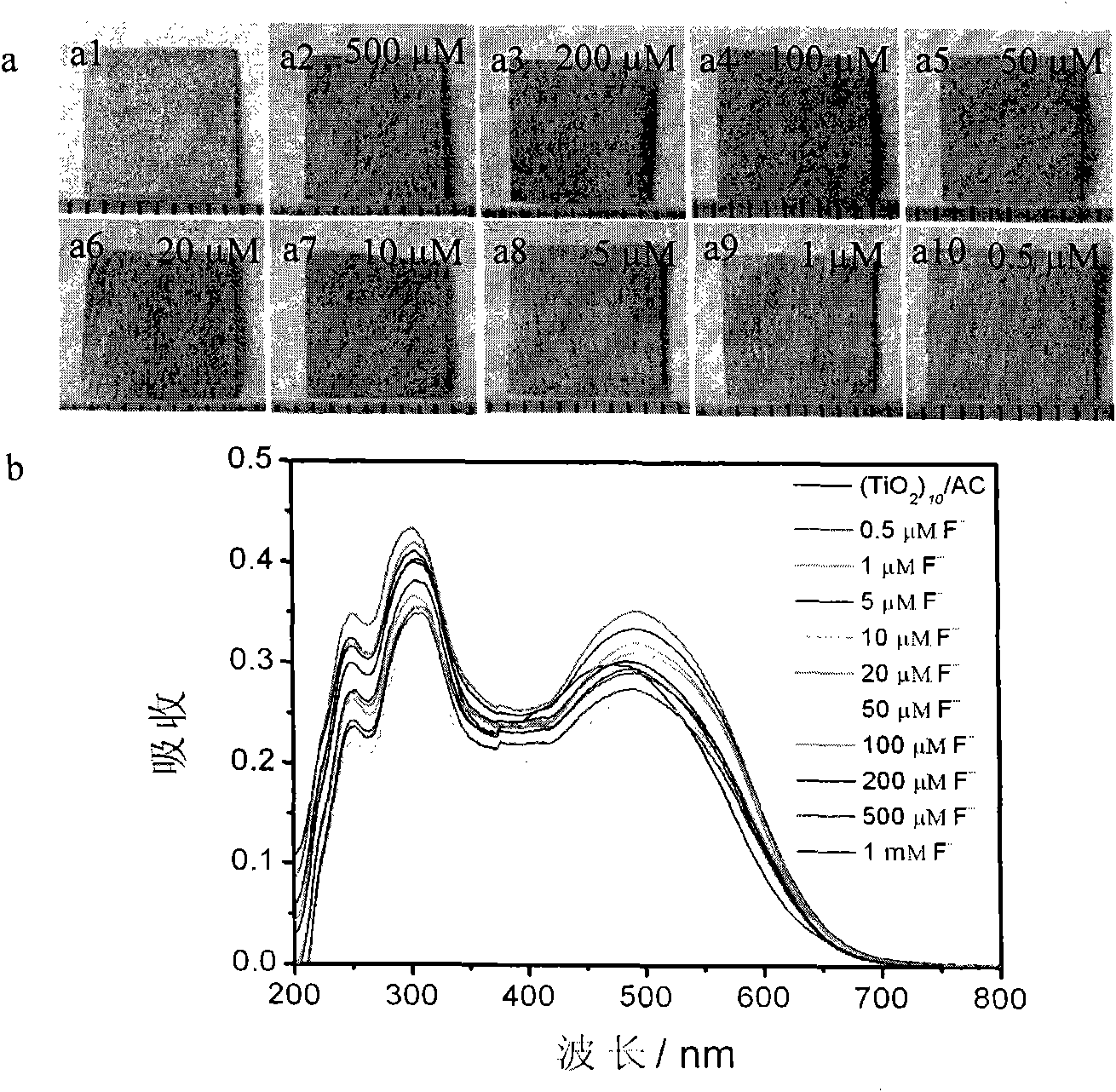

[0031] Embodiment 1: Prepare anionic colorimetric sensing cellulose material with the method provided by the present invention, and use this material to sense fluoride ions in aqueous solution:

[0032] Firstly, the anionic colorimetric sensing cellulose material in the present invention is prepared.

[0033] 1) Prepare a 100 mM tetrabutyl titanate solution in a solvent of toluene / ethanol (v:v=1:1), and stir at room temperature for 1 hour.

[0034] 2) Put ordinary quantitative filter paper in a suction filter device, rinse with ethanol for 2 to 3 times, and drain with air flow. Take 10 mL of tetrabutyl titanate solution and add it to the suction filtration device, and let it stand for 3 minutes, so that tetrabutyl titanate is deposited on the filter paper fiber.

[0035] 3) Slowly filter the tetrabutyl titanate solution under low vacuum. When the liquid level of the solution is close to the surface of the filter paper, add ethanol to rinse for 2 to 3 times, and let stand for 2 m

Embodiment 2

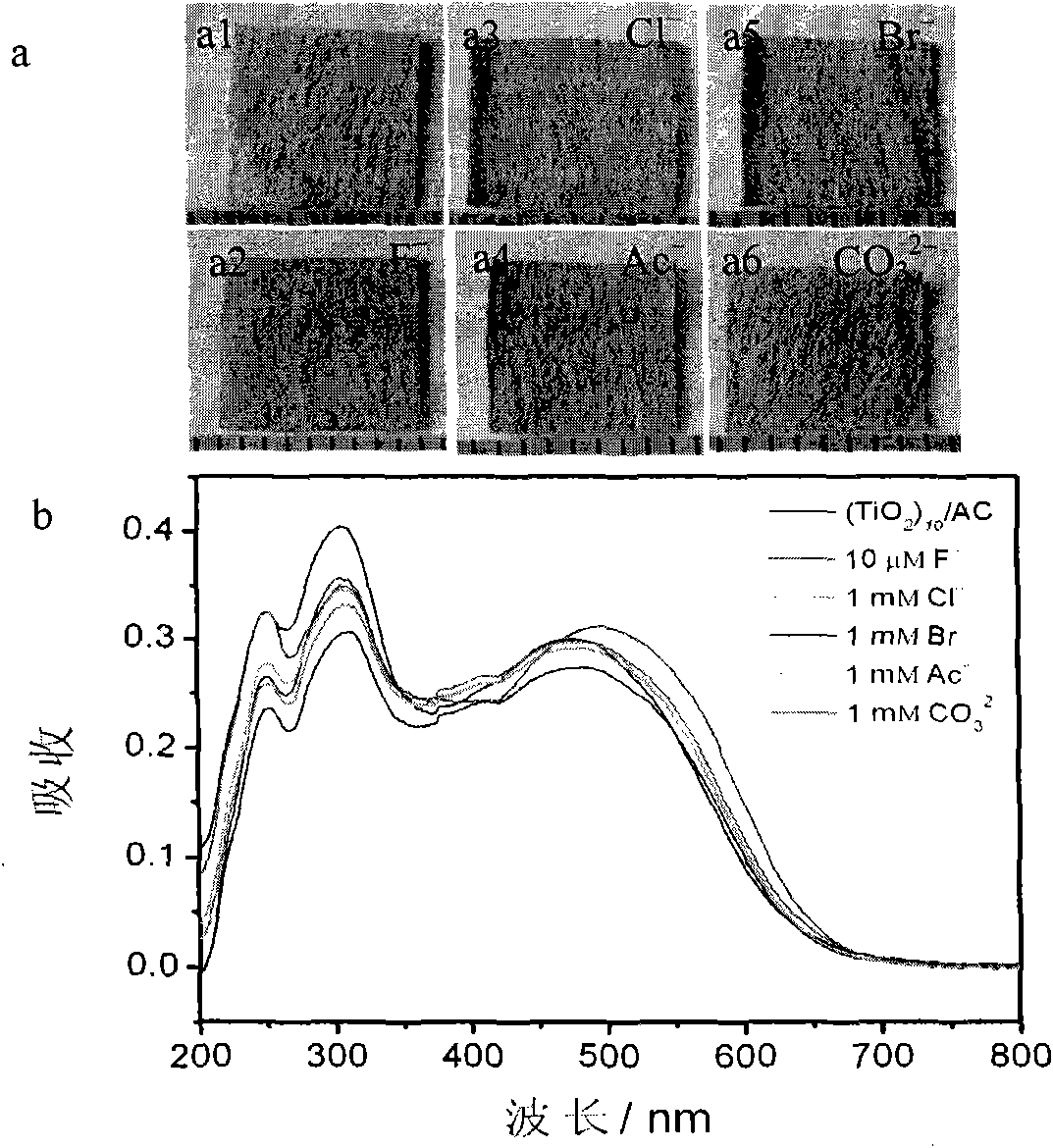

[0043] Embodiment 2: Prepare anion colorimetric sensing cellulose material with the method provided by the present invention, and use this material to detect other anions in aqueous solution:

[0044] Firstly, the anionic colorimetric sensing cellulose material in the present invention is prepared.

[0045] According to the preparation method and steps of Example 1, an anion colorimetric sensing cellulose material modified with alizarin complexing agent AC molecular monolayer was obtained, and it was used for the detection of other anions.

[0046] Put the self-assembled alizarin complexing agent AC molecular monolayer anion colorimetric sensing cellulose material in 1mM aqueous solution of different anions (chloride ion, bromide ion, acetate ion, carbonate ion) for 5 minutes, after taking out Physically adsorbed anions were removed by washing with water, and dried at room temperature. It can be found that even when the concentration of other anions is as high as 1 mM, it still

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap