Structure of sticking FRP fiber material on surface of concrete and implementation method thereof

A technology for concrete structures and concrete surfaces, applied in chemical instruments and methods, lamination devices, laminations, etc., can solve the problems of complex structure, unsatisfactory strength and bonding effect, etc., achieve small processing workload, avoid wear and tear and Impact, effect of increasing fire resistance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

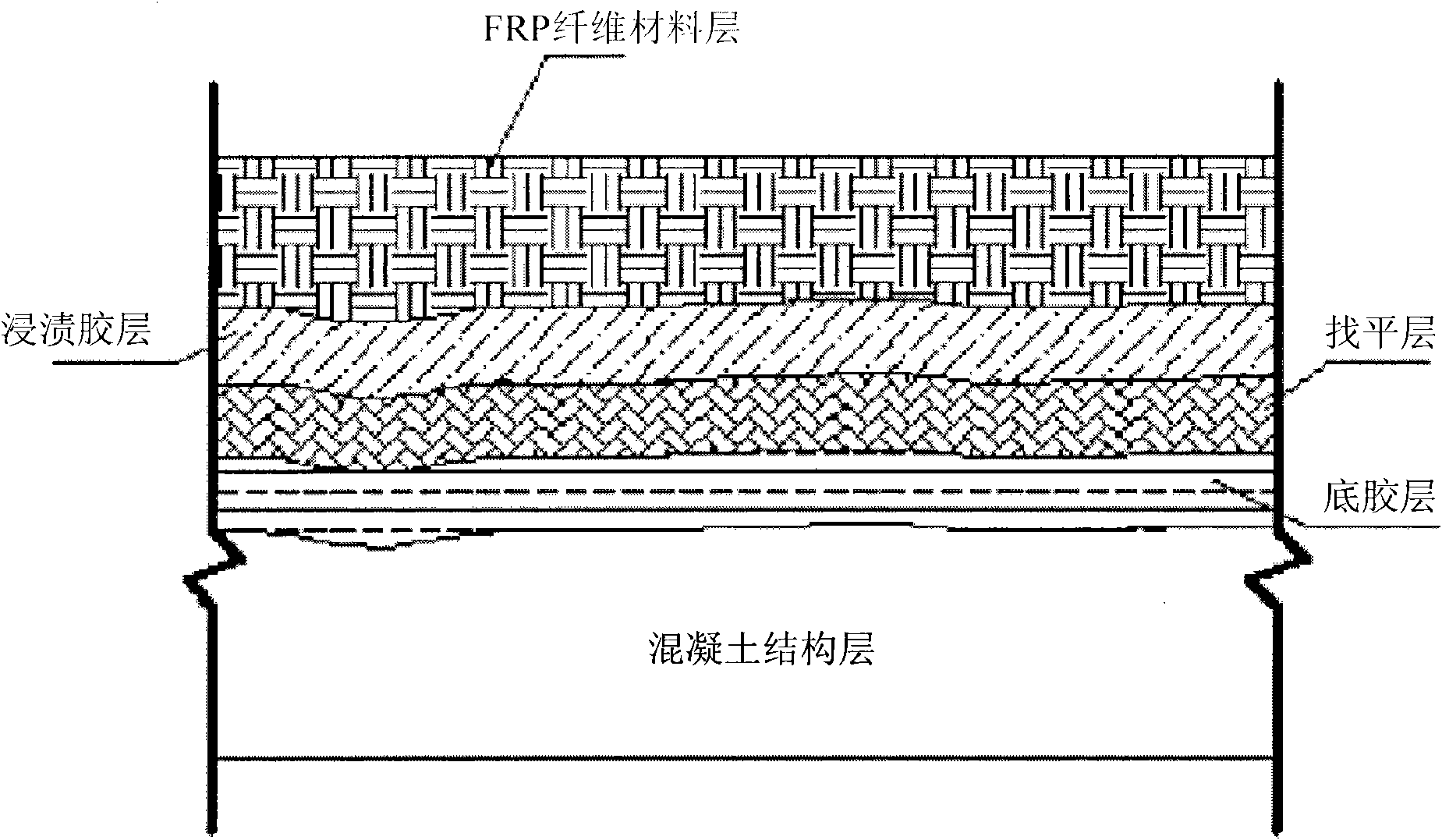

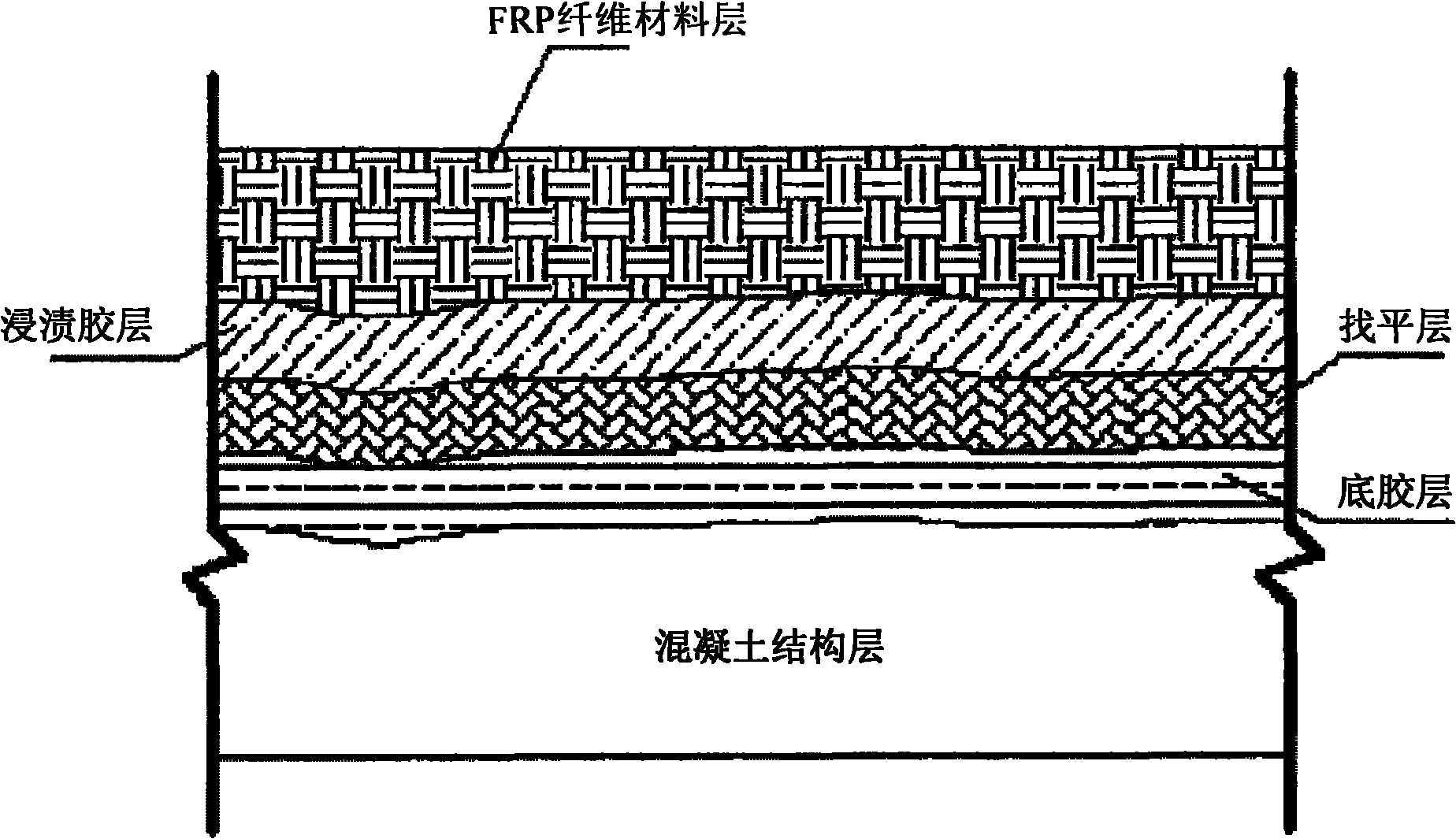

[0021] Such as figure 1 As shown, the present invention is mainly composed of a concrete structure layer, a primer layer, a leveling layer, an impregnated glue layer and an FRP fiber material layer laminated on the surface in sequence. Wherein, the primer layer, the leveling layer and the impregnated adhesive layer are respectively composed of the primer adhesive, the leveling adhesive and the impregnated adhesive in the structural adhesive. The structural adhesive plays an important role in the present invention. It plays a bonding role between the FRP fiber material and the concrete structure layer and transmits the macroscopic mechanical properties in the system.

[0022] Before painting the primer on the concrete surface, it is necessary to treat the surface of the loose and weak concrete structure layer to the hard interface of the concrete. Then apply the primer to improve the strength of the concrete surface and the bonding of the concrete structure layer and the adhesive

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap