Six-operating-condition bidirectional tide power generation water turbine

A tidal power generation and water turbine technology, which is applied in the direction of tidal flow/damless hydropower, hydropower, ocean energy power generation, etc., can solve the problems of large vibration and pressure pulsation, large dynamic stress of runner blades, poor operation stability of the unit, etc. Improved operational stability, reduced vibration and pressure pulsations, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] The present invention provides a six-mode two-way tidal power generation hydraulic turbine. The present invention will be further described below with reference to the drawings and specific embodiments.

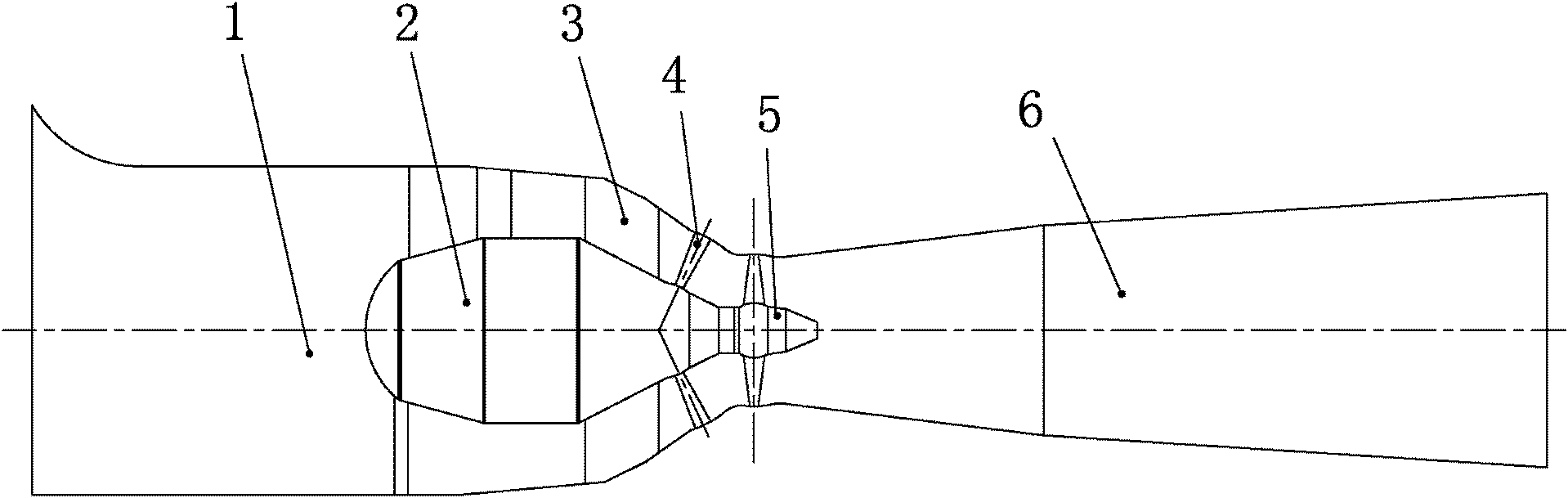

[0026] Such as figure 1 As shown, the turbine includes an inlet pipe 1, a tubular base 3, and a draft tube 6, which are connected in sequence, and a bulb body 2, which is arranged in the tubular base 3, connected to the end of the bulb body 2 and the inner wall of the tubular base 3. A plurality of guide vanes 4, a runner 5 installed at the junction of the tubular seat 3 and the draft tube 6;

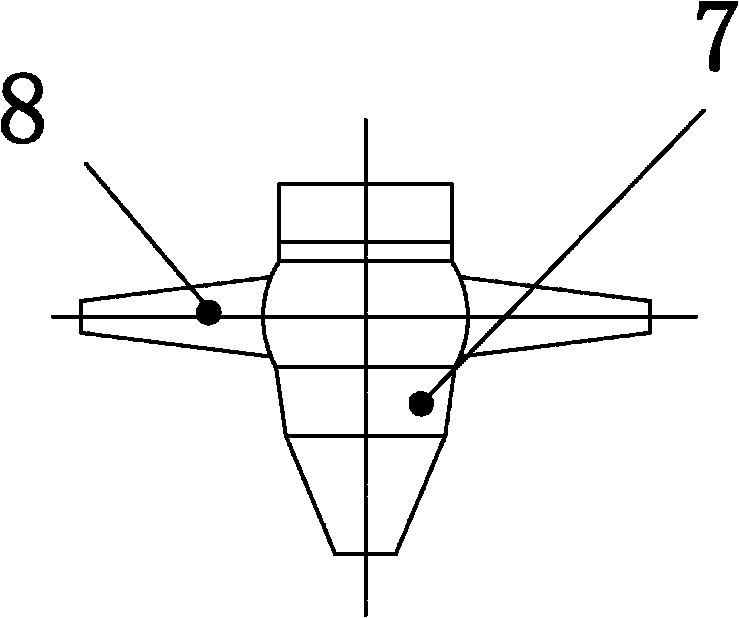

[0027] Such as figure 2 As shown, the structure of the runner 5 is as follows: a plurality of water turbine blades 8 are installed on the side of the hub body 7, and the water turbine blades 8 can rotate around its own pivot. Here, 4 water turbine blades are selected.

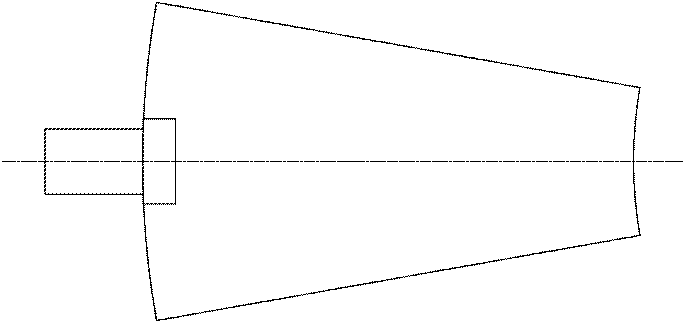

[0028] Such as image 3 with Figure 5 As shown, the middle section of the guide vane 4 is designed as a brand new prof

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap