Heat exchanger for gas water heater

A technology of gas water heaters and heat exchangers, which is applied to fluid heaters, lighting and heating equipment, etc. It can solve problems such as poor turbulence effects, fires, and scarcity of copper materials, so as to reduce material costs, prevent poisoning accidents, and ensure safety high performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

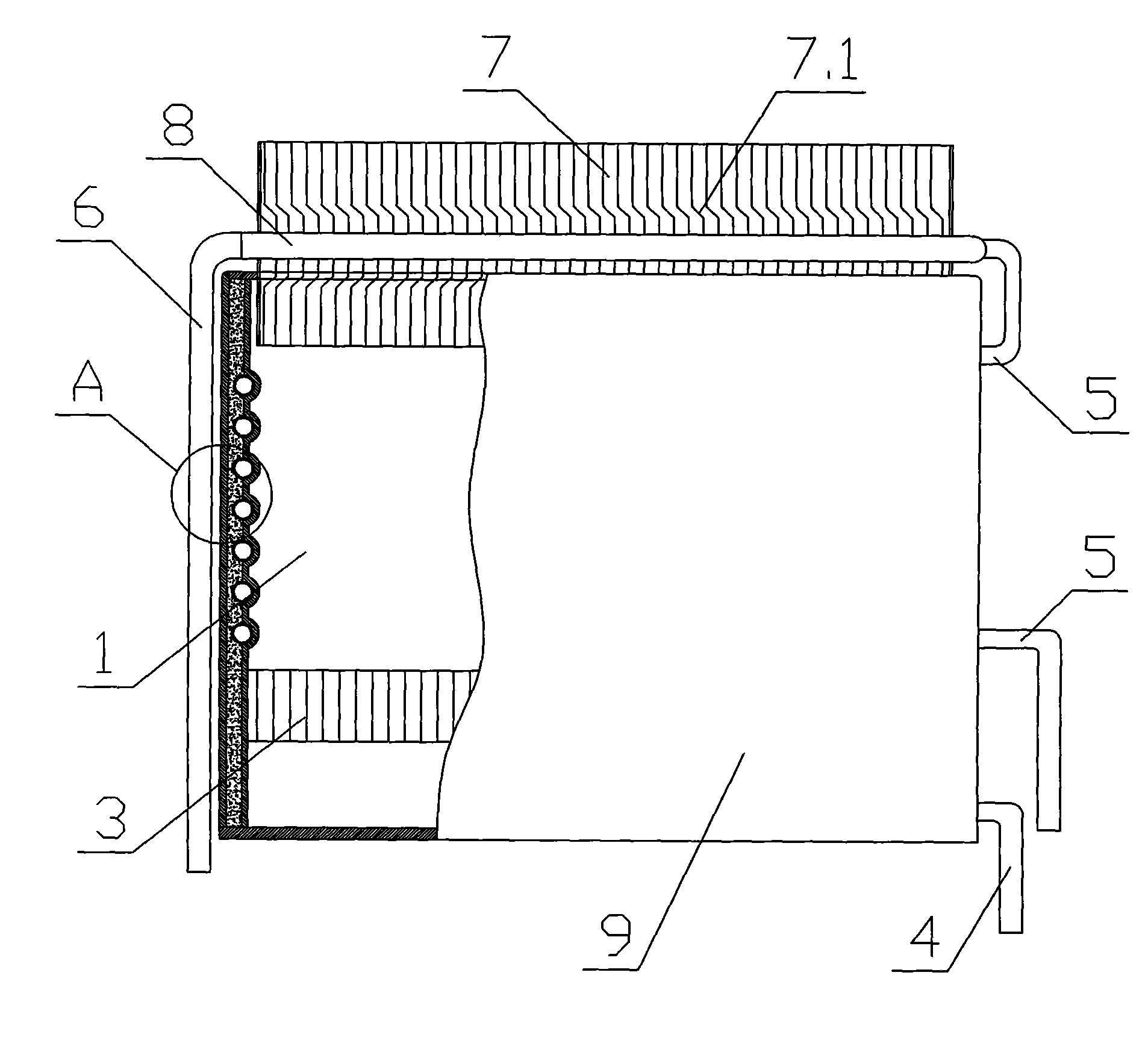

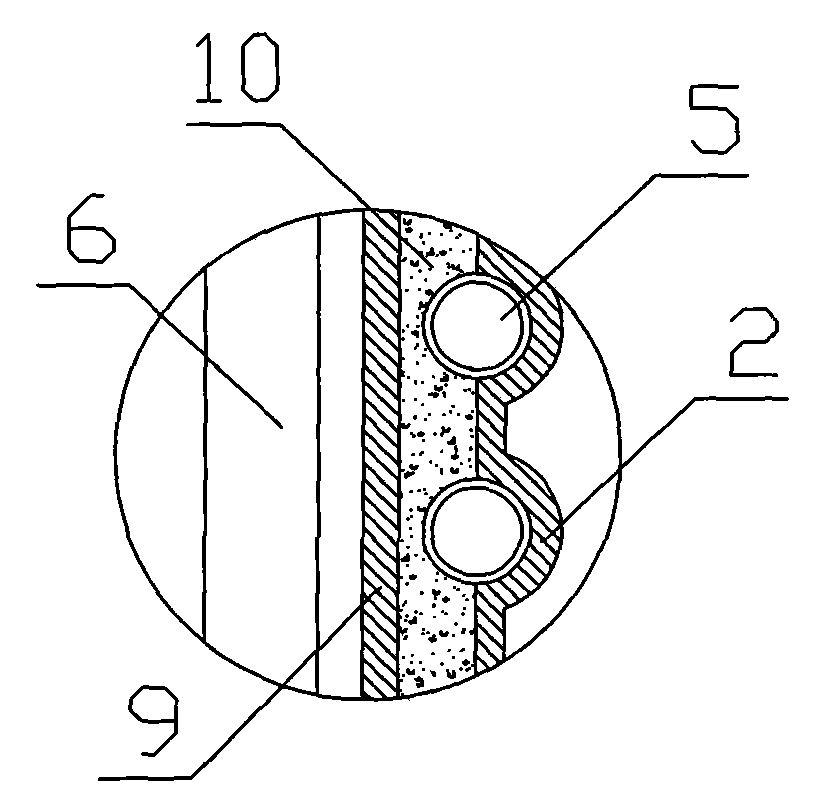

[0024] Example one: such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the heat exchanger for a gas water heater of the present invention mainly consists of a combustion chamber 1, a cavity inner wall 2, a burner 3 provided in the combustion chamber 1, an air inlet pipe 4 for supplying gas to the burner 3, and a water inlet pipe 5. , The outlet pipe 6 and tube-fin heat exchanger, the burner 3 can be infrared burner or earth burner, etc. The tube-fin heat exchanger is arranged above the combustion chamber 1, including fins 7 and passing through the fins. The water pipe 8 on the sheet 7, the water inlet pipe 5 is connected to one end of the water pipe 8, and the water outlet pipe 6 is connected to the other end of the water pipe 8. Since the inside of the firing chamber 1 is a high-temperature area, the fins 7 and the cavity inner wall 2 of the tube-fin heat exchanger can be stamped and formed with thin metal sheets resistant to high temperature and oxidation, such as shee

Example Embodiment

[0025] Embodiment two: such as Figure 4 As shown, the main structure is basically the same as that of the first embodiment, except that the heat exchange fins 11 can be provided on the inner wall 2 of the cavity to increase the heat exchange capacity.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap