Intelligent monitoring device for temperature and insulation state of 330KV high-voltage cable in hydropower station

A 330KV, high-voltage cable technology, used in measuring devices, thermometers, testing dielectric strength, etc., can solve the problem of inability to adapt to the special environment of hydropower stations, and achieve the effect of reducing labor intensity, improving production efficiency, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

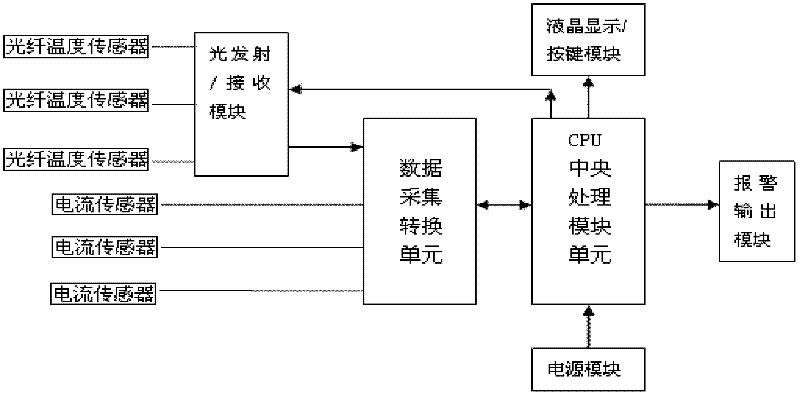

[0033] see figure 1 In the present embodiment, the 330KV high-voltage cable temperature and insulation state intelligent monitoring device of the hydropower station is composed of an optical fiber temperature sensor, a current sensor, a light emitting / receiving module, a data acquisition conversion unit, a CPU central processing module unit, a liquid crystal display / key module, and an alarm output modules and power modules. The fiber optic temperature sensor directly measures the temperature of the high-voltage cable joint, and is connected with the light emitting / receiving module through an optical fiber. The light emitting / receiving module photoelectrically converts electrical signals and is connected with the data acquisition conversion unit, and the control signal of the light emitting / receiving module is sent by the CPU central processing module unit. The current sensor is installed on the metal sheath of the high-voltage cable joint to directly measure the leakag

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap