Closed durable moistureproof and anticorrosion ozone sheet

A closed and durable technology, used in the field of ozone sheets, can solve the problems of easy current breakdown of the insulating layer, complicated use environment of ozone sheets, corrosion of metal electrodes, etc., and achieves stable working performance, long service life, and large amount of ozone generation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

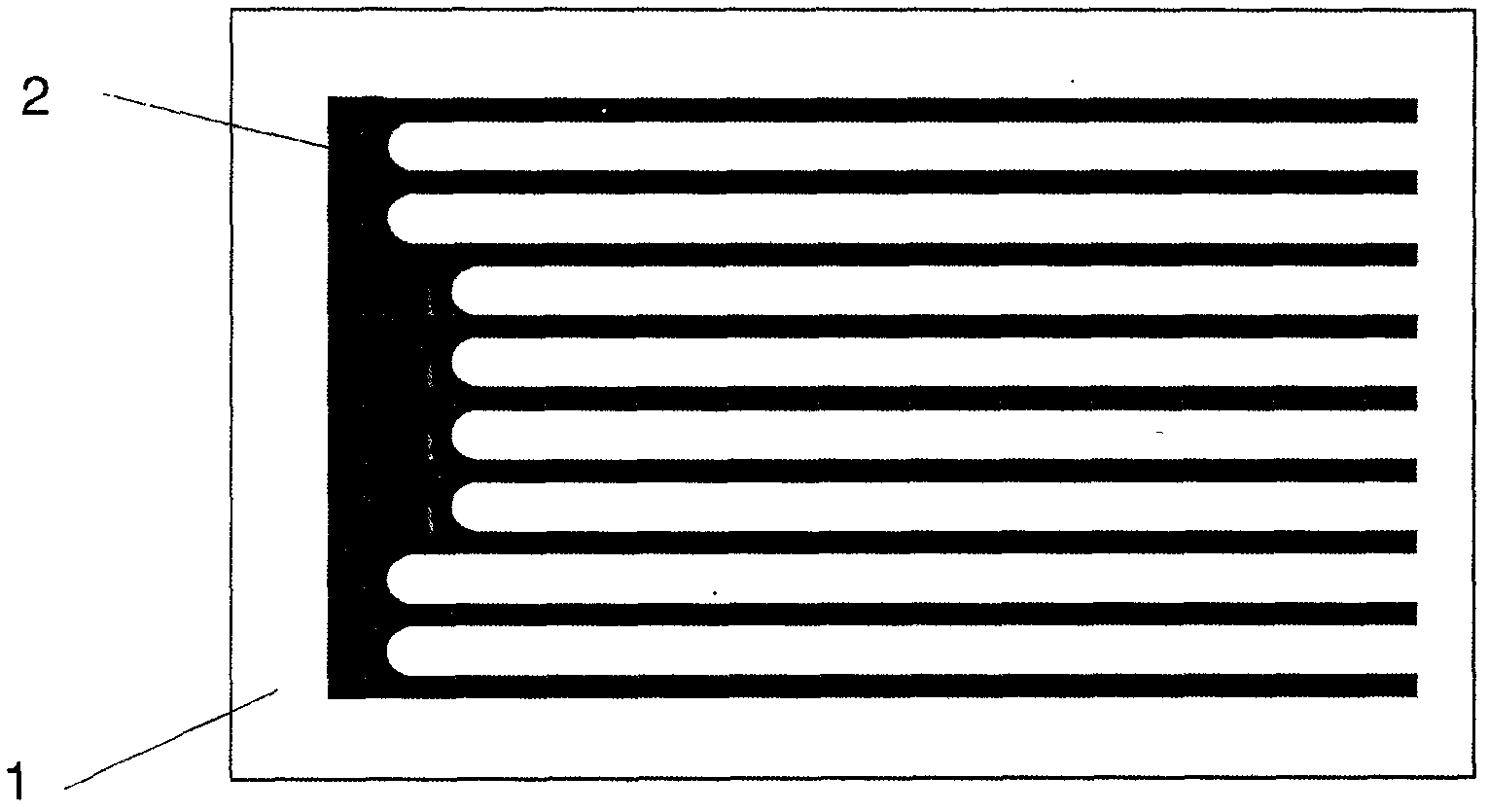

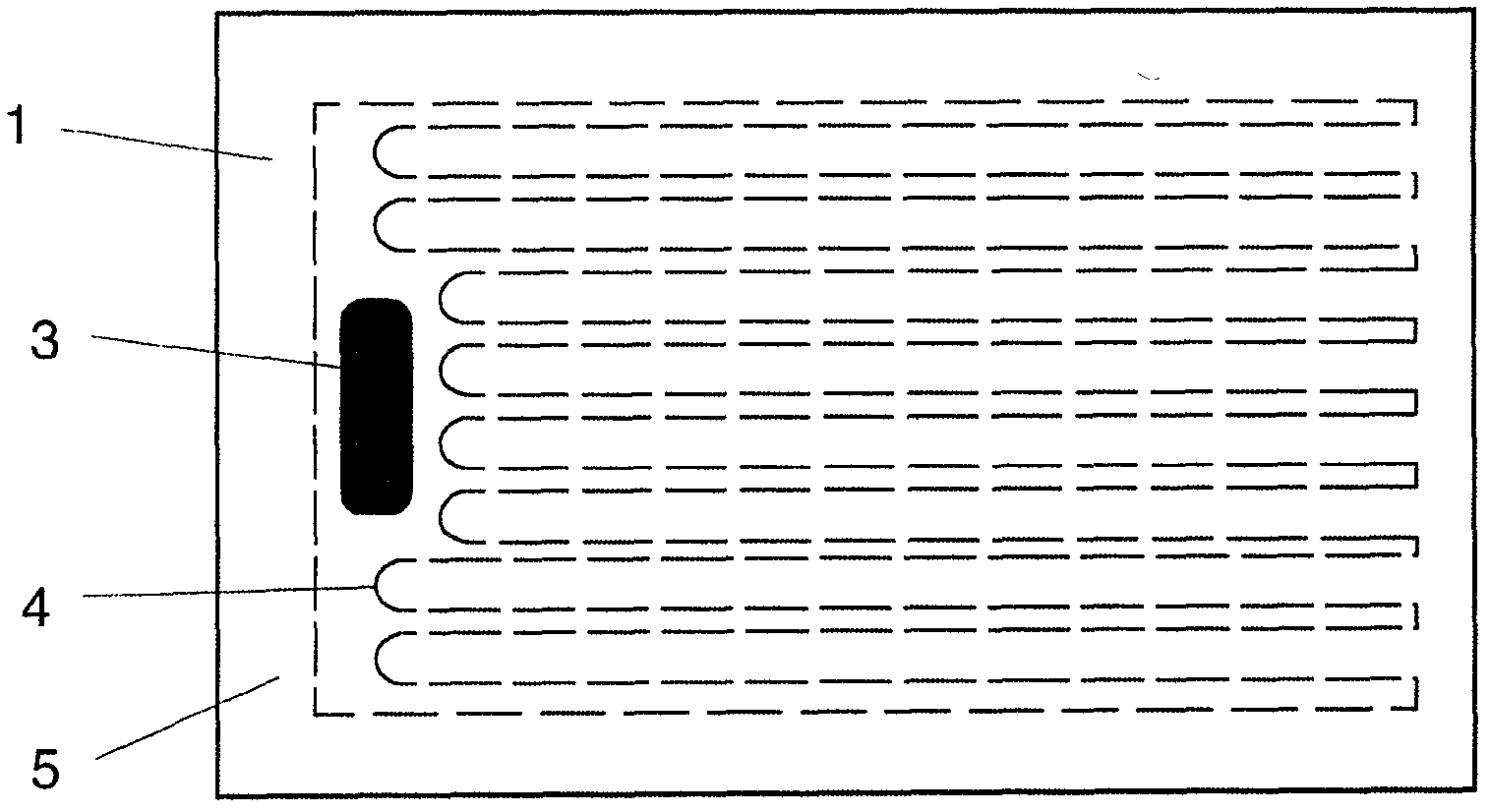

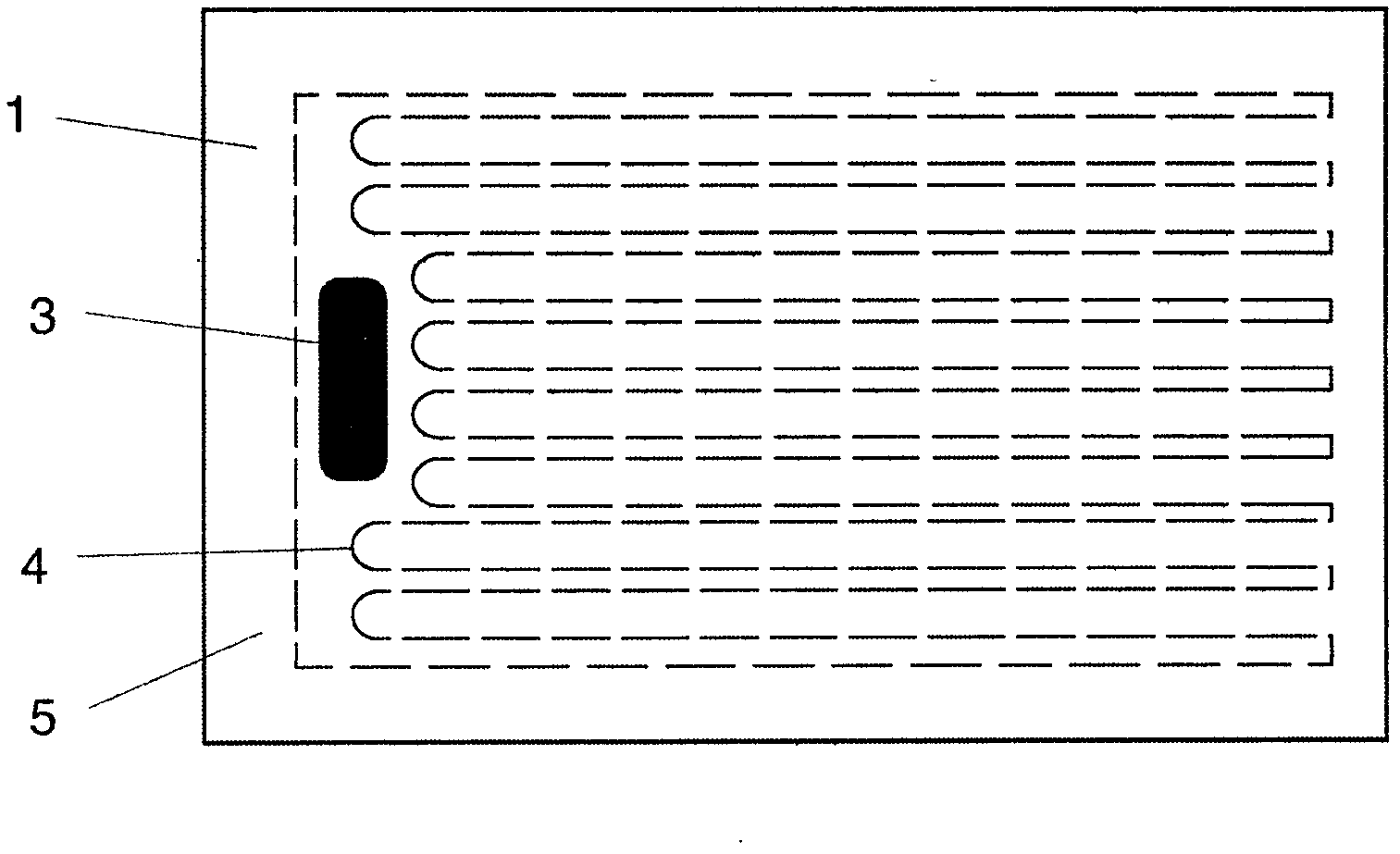

[0011] Such as figure 1 , figure 2 As shown, the closed durable moisture-proof and rot-proof ozone sheet is composed of an alumina ceramic substrate 1, an outer alumina ceramic substrate 5, an electrode slurry 2, and an inner layer electrode slurry 4. It is characterized in that the oxidation One side base surface of aluminum ceramic substrate 1 is attached with printed electrode paste 2, and the base surface of the other side is attached with inner layer printed electrode paste 4, and this side and the outer layer alumina ceramic substrate 5 of the same specification overlapped, and sintered and fused together; one end of the outer alumina ceramic substrate 5 is reserved with a welding hole 3 , and a part of the inner layer electrode paste 4 is exposed in the welding hole 3 .

[0012] The preparation method of the ozone sheet of the present invention: the main component of the alumina ceramic substrate 1 and the outer layer alumina ceramic substrate 5 in the ozone sheet is Al

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap