Preparation method for vacuum drying of transglutaminase

A technology of transglutaminase and vacuum drying, which is applied in the direction of transferase, etc., can solve the problems of unfavorable large-scale industrial production, poor anti-oxidation, and difficult storage, and achieve obvious anti-oxidation effect, good stability, and improved The effect of antioxidant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of vacuum-drying transglutaminase of the present invention comprises the following steps: adding a thermoprotectant to the fermented liquid of transglutaminase, standing at room temperature, obtaining supernatant through high-speed refrigerated centrifugation, and using 95% ethanol to The supernatant is precipitated, and the precipitate is obtained by high-speed refrigerated centrifugation, and an antioxidant protection agent is added, mixed evenly, and vacuum-dried to obtain a transglutaminase enzyme preparation; wherein, the heat protection agent is a sugar alcohol substance, including sorbic acid Sugar alcohols and maltitol, antioxidant protection including active peptides.

[0028] Wherein, the enzyme activity of the transglutaminase in the transglutaminase fermented liquid is 10-50 u / ml.

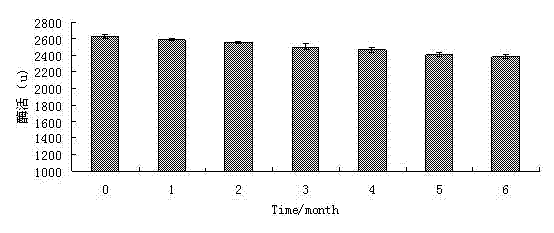

[0029] In the present invention, the added amount of sorbitol is 0.5%~5%w / v, preferably 0.5%~2%w / v. The added amount of maltitol is 1%~10%w / v, prefer

Embodiment 1

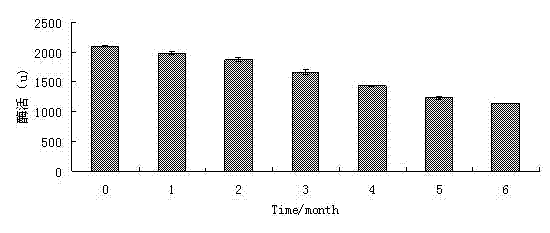

[0036] to Streptomyces mobara ( Streptoverticillium mobaraense) into 100ml of transglutaminase fermentation broth produced by adding ethanol at a volume ratio of 0.5:1 ethanol:fermentation broth to precipitate the enzyme, and set the high-speed refrigerated centrifuge at 6000r / min, 4°C, and centrifuge for 20min to obtain the precipitate put the precipitate into a vacuum drying oven, and dry at 40° C. for 3 hours to obtain a transglutaminase preparation. Seal it with a ziplock bag, and measure the enzyme activity regularly.

Embodiment 2

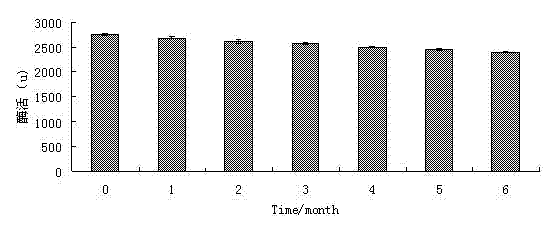

[0038] to Streptomyces mobara ( Streptoverticillium mobaraense ) into 100ml of transglutaminase fermentation broth produced by adding 1% (w / v) sorbitol, stirring and standing at room temperature for 30min, adding ethanol at a volume ratio of 0.5:1 ethanol:fermentation broth to precipitate the enzyme , high-speed refrigerated centrifuge setting: 6000r / min, 4°C, centrifuge for 20min to obtain a precipitate, put the precipitate into a vacuum drying oven, and dry at 40°C for 3h to obtain a transglutaminase enzyme preparation. Seal the bag with a ziplock, and measure the enzyme activity regularly.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap