Adjusting method of resonant cavity

An adjustment method and resonant cavity technology, applied in the field of lasers, can solve the problems of inability to achieve laser maintenance and debugging, increased difficulty in adjusting the resonant cavity, larger spot size, etc., and achieve the effects of simple structure, low cost, and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

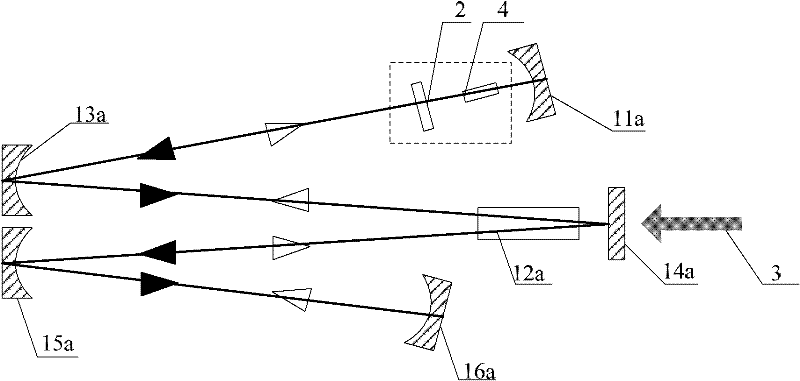

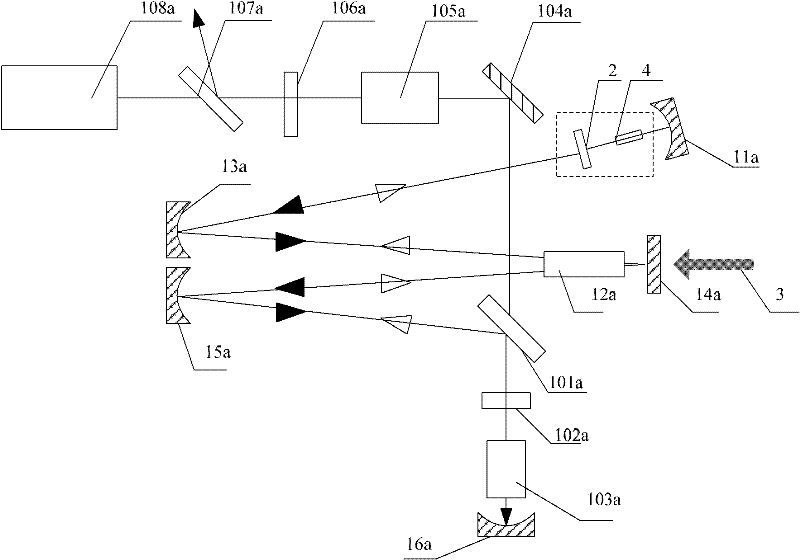

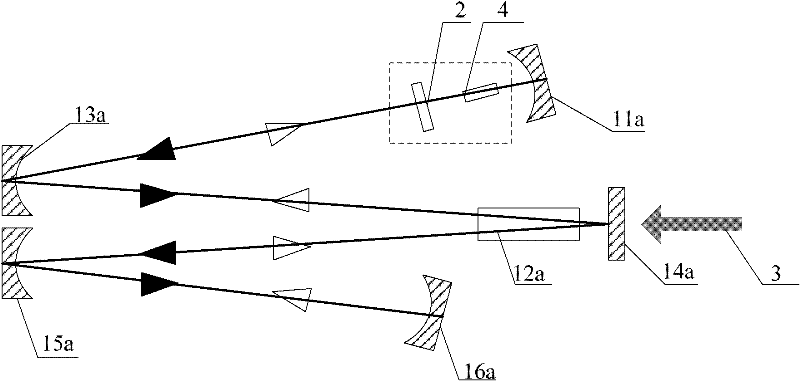

[0016] The adjustment method of the resonant cavity of the present invention comprises the following four steps:

[0017] Step 1: Set the first-end resonant mirror and the second-end resonant mirror at both ends of the optical path of the resonator respectively, and set at least two reflective cavity mirrors between the first-end resonant mirror and the second-end resonant mirror and arranged sequentially along the optical path, the gain medium is arranged between two adjacent reflective cavity mirrors;

[0018] Step 2: Put the signal light gain medium between the first resonant cavity mirror in the resonant cavity optical path and the reflective cavity mirror closest to the first end resonant cavity mirror, and put the signal light output mirror into the signal in the resonant cavity optical path The side of the optical gain medium away from the first end resonant cavity mirror, and the signal light output mirror, the signal light gain medium and the first end resonant cavity mi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap