Intelligent digital hydraulic-control four-roller reversing finishing mill

A digital hydraulic and intelligent technology, applied in the direction of rolling mill control device, metal rolling stand, metal rolling stand, etc., can solve the problems of restricting wide application, unfavorable technological transformation of production enterprises, complex structure of cold rolling mill, etc., to achieve Good adjustability, shortened transmission distance, clean and tidy equipment as a whole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

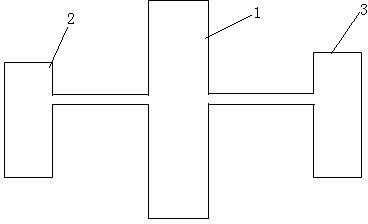

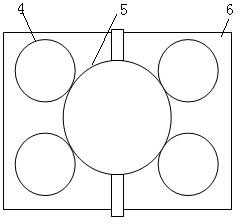

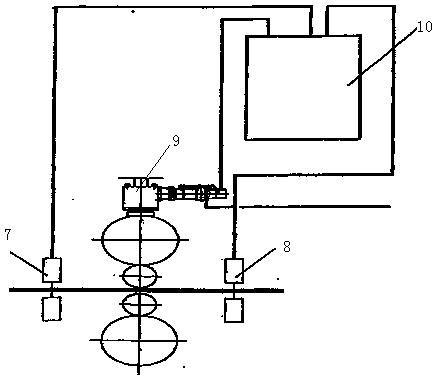

[0020] Such as figure 1 As shown, it includes a main frame base 1, a left coiling frame base 2 and a right coiling frame base 3, the main frame is provided with upper and lower work rolls and upper and lower support rolls, and the main frame base The base, the left coiling frame base and the right coiling frame base are connected as a whole and set in the integral foundation; the main frame is provided with a motor connected in sequence, a combined gearbox, upper and lower work rolls, and a combined gear A reducer and a gear are arranged in the box; the two ends of the upper and lower work rolls are respectively connected to the main frame through tile seats; figure 2 As shown, the four corners of the tile seat 6 are respectively provided with grooves 4 for installing bearings, the work roll bushing 5 is arranged in the tile seat, the outer peripheral surface of the wor

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap