Phosphorus-containing fire retardant and preparation method thereof

A flame retardant, phosphoryl hydroquinone carbonate technology, applied in the field of flame retardants, can solve the problems of melt dripping, flame retardant thermal stability, compatibility and low flame retardant efficiency, and achieve reaction Fast speed, guaranteed durability, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

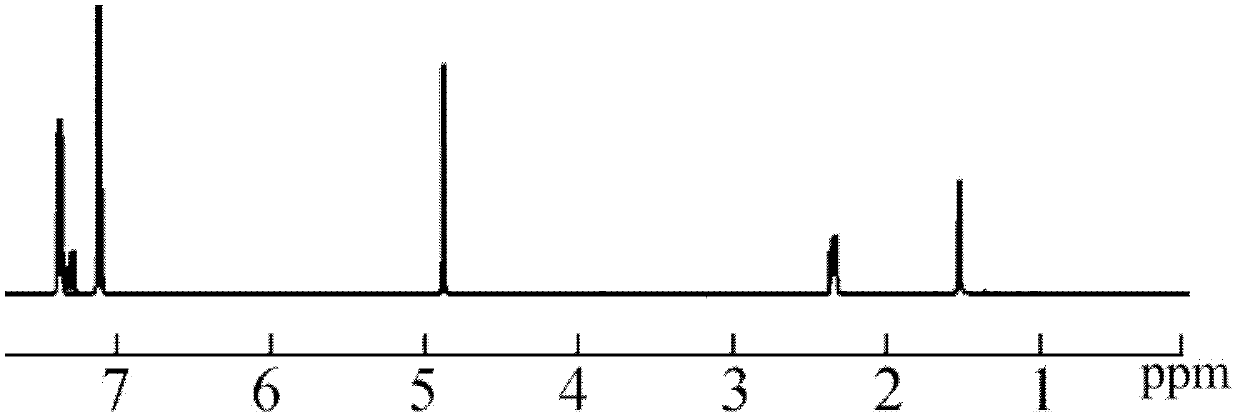

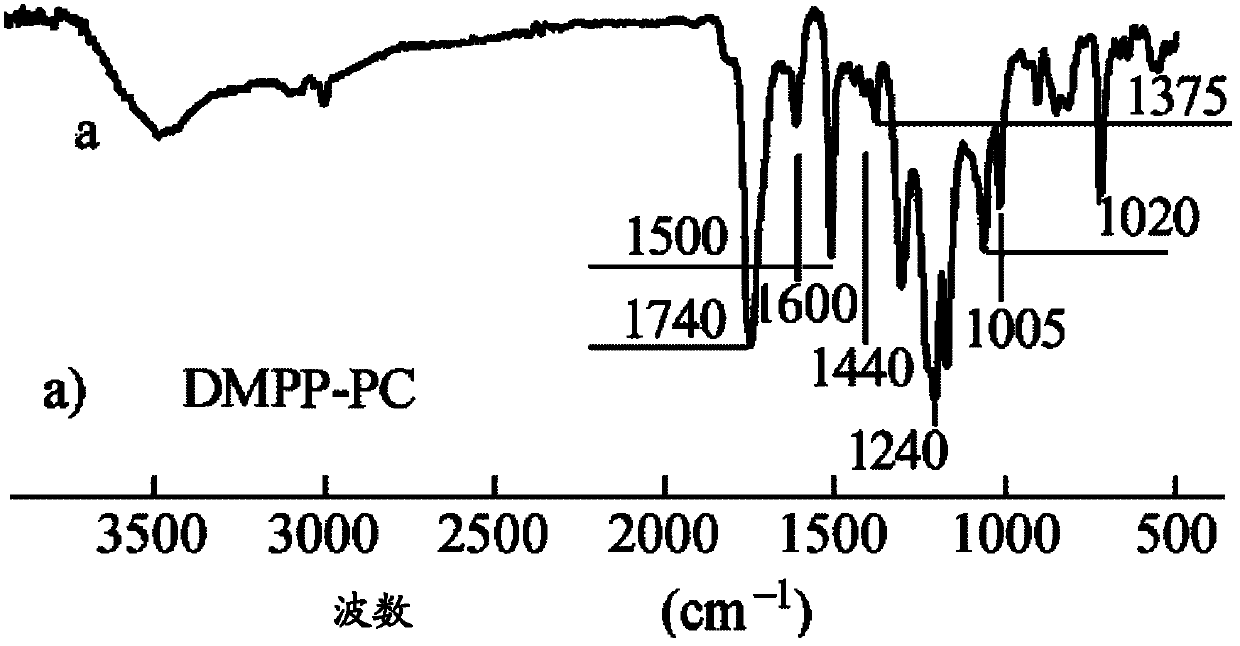

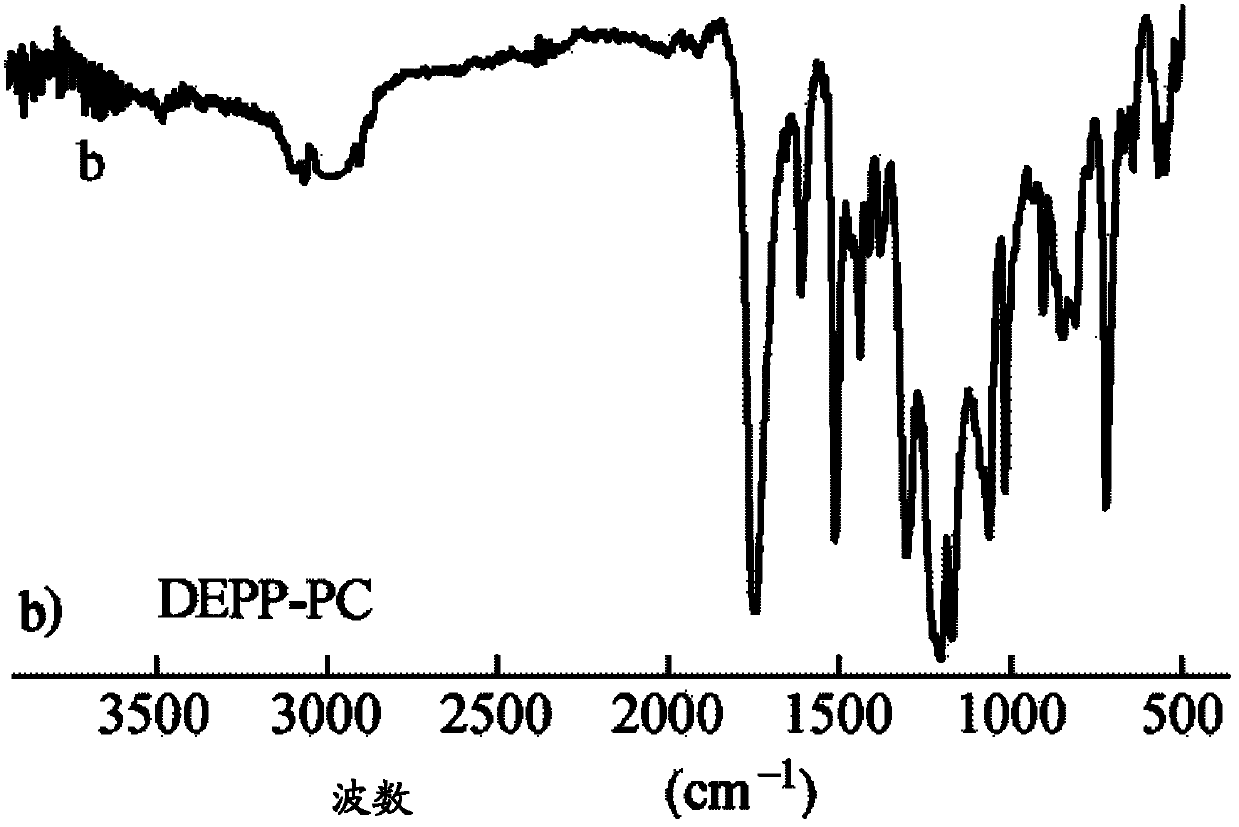

[0061] The preparation method of phosphorus-containing flame retardant provided by the invention, general reaction formula is as follows:

[0062]

[0063] Including the following steps:

[0064] (1) Add measured bisphenol A, phosphorus-containing hydroquinone derivatives, and a polymerization catalyst (IPTC) into a reaction vessel containing 600 mL of sodium hydroxide aqueous solution (sodium hydroxide concentration is 0.04 g / mL) to form a uniform solution;

[0065] (2) Slowly add the solution obtained in step (1) dropwise into an organic solvent containing metered triphosgene (the content of triphosgene in the organic solvent is 0.075g / mL), keep the solution below 15°C and drop 0.5- After 2 hours, after the dropwise addition, keep the solution temperature at 0-30°C, pH value at 9-10, react for 1-3 hours, remove the aqueous phase solution, separate the organic phase, and obtain a crude phosphorus-containing flame retardant;

[0066] (3) The crude product obtained in ste

Embodiment 1

[0087]In Example 1, the specific steps for preparing a phosphorus-containing flame retardant are as follows:

[0088] (1) 0.068mol (15.5 grams) of bisphenol A, 0.23mol (42.81 grams) of dimethylphosphine-1,4-hydroquinone, 0.03mol of 4-(N,N'-dimethylamino) Pyridine was added into a reaction vessel containing 600mL aqueous sodium hydroxide solution (sodium hydroxide concentration was 0.04g / mL) to form a homogeneous solution;

[0089] (2) The solution obtained in step (1) is slowly added dropwise to 376mL of organic solvent containing 0.1mol (28.2 grams) of triphosgene, (the content of triphosgene in the organic solvent is 0.075g / mL), keep the solution at 15 Add dropwise for 0.5-2 hours below ℃, after the dropwise addition, keep the solution temperature at 10-30°C, pH value at 9-10, react for 1-3 hours, remove the aqueous phase solution, separate the organic phase, and obtain the crude product containing Phosphorus flame retardant;

[0090] (3) The crude product obtained in ste

Embodiment 2

[0100] In embodiment 2, prepare phosphoryl hydroquinone carbonate copolymer according to the above-mentioned method, determine the consumption of raw material according to the molar proportion shown in table 1,

[0101] The molar ratio of bisphenol A to DMPP is 45:55; the molar ratio of the sum of bisphenol A and DMPP to triphosgene is 100:33; the molar ratio of polymerization catalyst to triphosgene is 15:33.

[0102] In the same way, in theory, in the phosphoryl hydroquinone carbonate copolymer prepared in Example 2, (m+p): o=1: 1; p: m=0.8: 1; the mole of polymerization catalyst and triphosgene The ratio is 0.45:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap