Inserting and hanging type decorative component for decoration in elevator car

A technology for elevator car and interior decoration, applied to elevators, transportation and packaging in buildings, etc., can solve the problems of inconvenience in use, long elevator downtime, etc., and achieve flexible use, fast and flexible installation, and clever conception. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: A plug-in decoration component for elevator car interior decoration

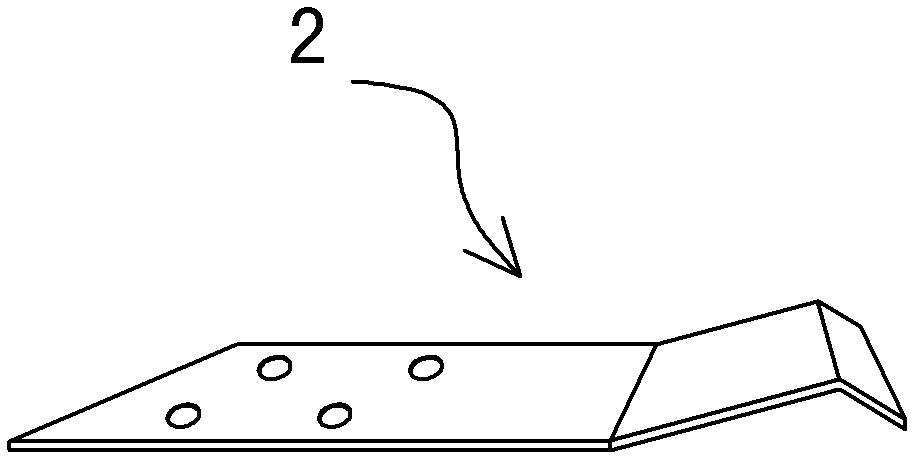

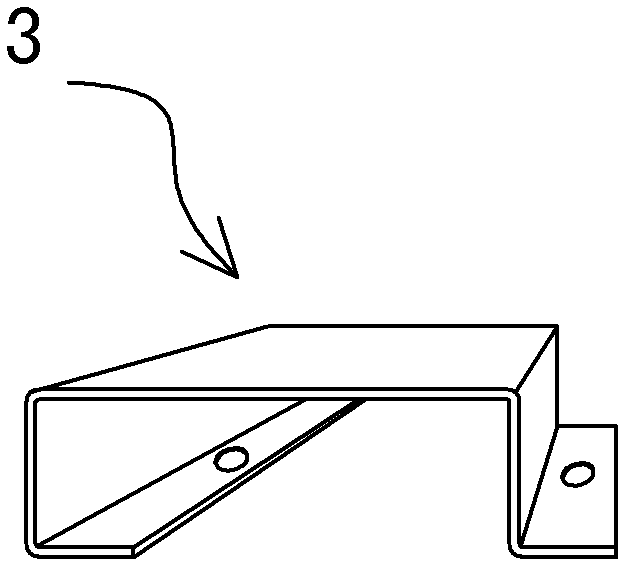

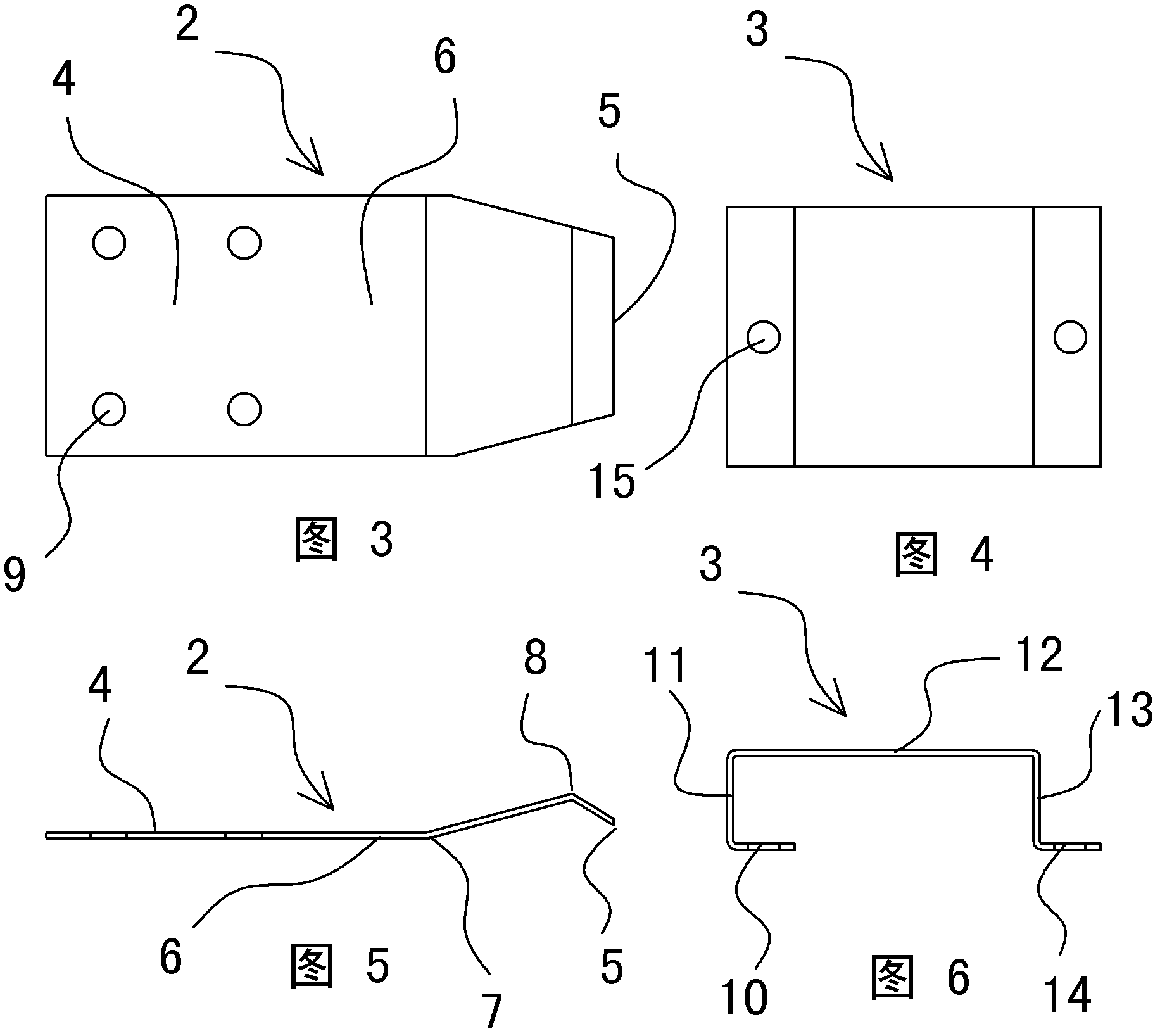

[0036] Such as Figure 7 with Figure 8 As shown, the plug-in decoration assembly is composed of a decorative board 1 and at least one pair of plug-in clips, wherein each pair of plug-in clips is composed of a male clip 2 and a female clip 3 . Figure 7 with Figure 8 Although only a pair of hanging clips is shown, this embodiment is not limited to the case of using a pair of hanging clips. In practical applications, the number of clips used usually depends on the shape and size of the decorative panel 1. The purpose is to firmly and reliably fix the decorative panel 1 to the car wall and meet the requirements of the elevator car. In addition, the number of hanging clips used is related to the elastic force or pressure that each pair of hanging clips can provide. Generally, if the elastic force or pressure that each pair of hanging clips can provide is large, the number can be reduced ac

Embodiment 2

[0043] Embodiment 2: A plug-in decorative component for elevator car interior decoration

[0044] Such as Figure 16 As shown, the plug-in decoration assembly is composed of a decorative board 1 and at least one pair of plug-in clips, wherein each pair of plug-in clips is composed of a male clip 2 and a female clip 3 . Figure 16 Although only a pair of hanging clips is shown, this embodiment is not limited to the case of using a pair of hanging clips.

[0045] Such as Figure 10 , Figure 12 with Figure 14 As shown, the female clip 3 of this embodiment is exactly the same as that of Embodiment 1, so the description will not be repeated.

[0046] The main difference between this embodiment and Embodiment 1 is that the folding direction of the first section 10 and the fifth section 14 on the female clip 3 is opposite, so that the two installation sections extend to both sides and form a pair for Fixed mount. This female clip 3 is not only suitable for being fixed on the bac

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap