Automatic root peeler for Pholiota nameko

A sliding mushroom, automatic technology, applied in application, food processing, food science, etc., can solve the problems of labor occupation, high labor intensity, low efficiency, etc., to reduce labor intensity, ensure harvest quality, and improve labor productivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

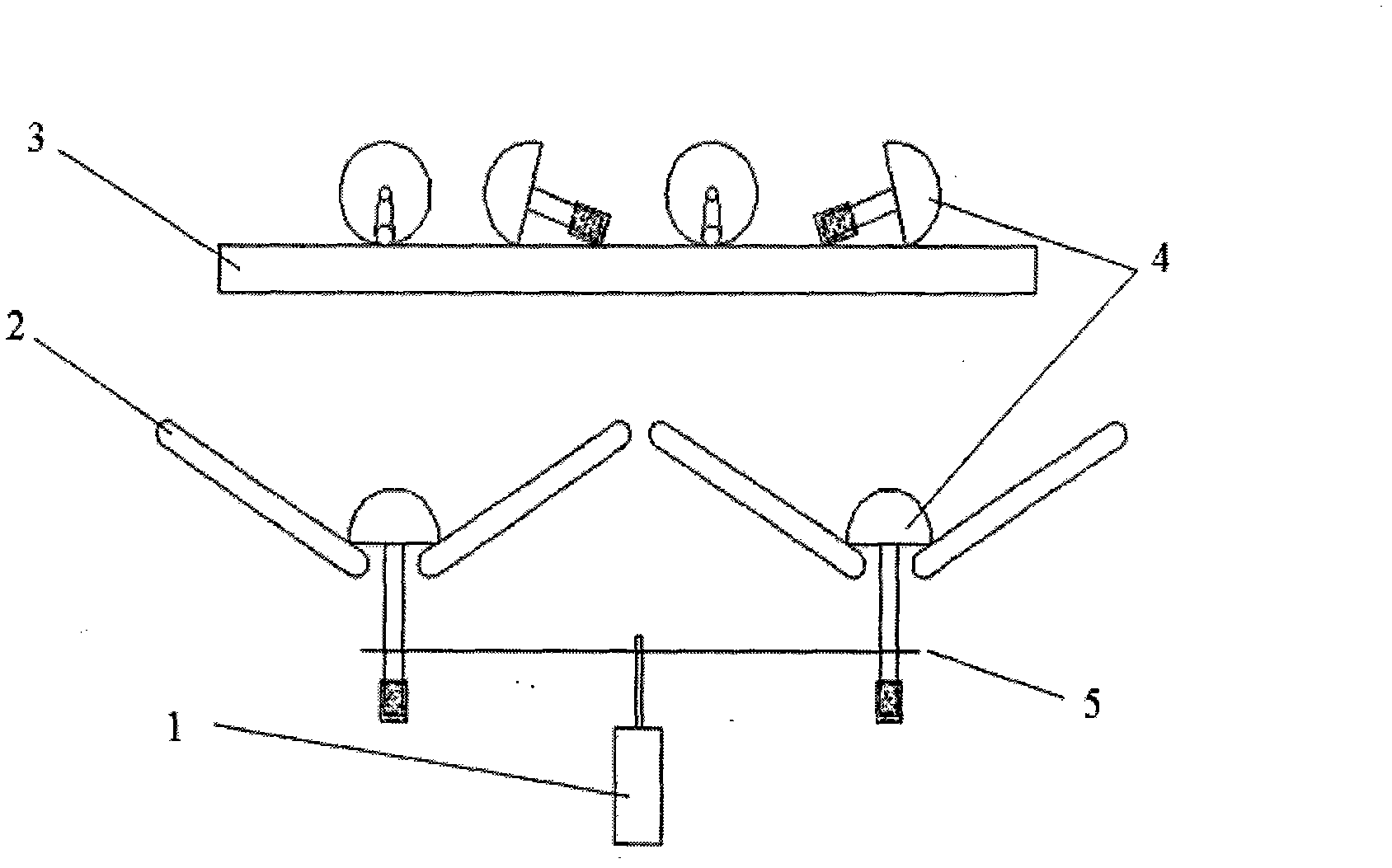

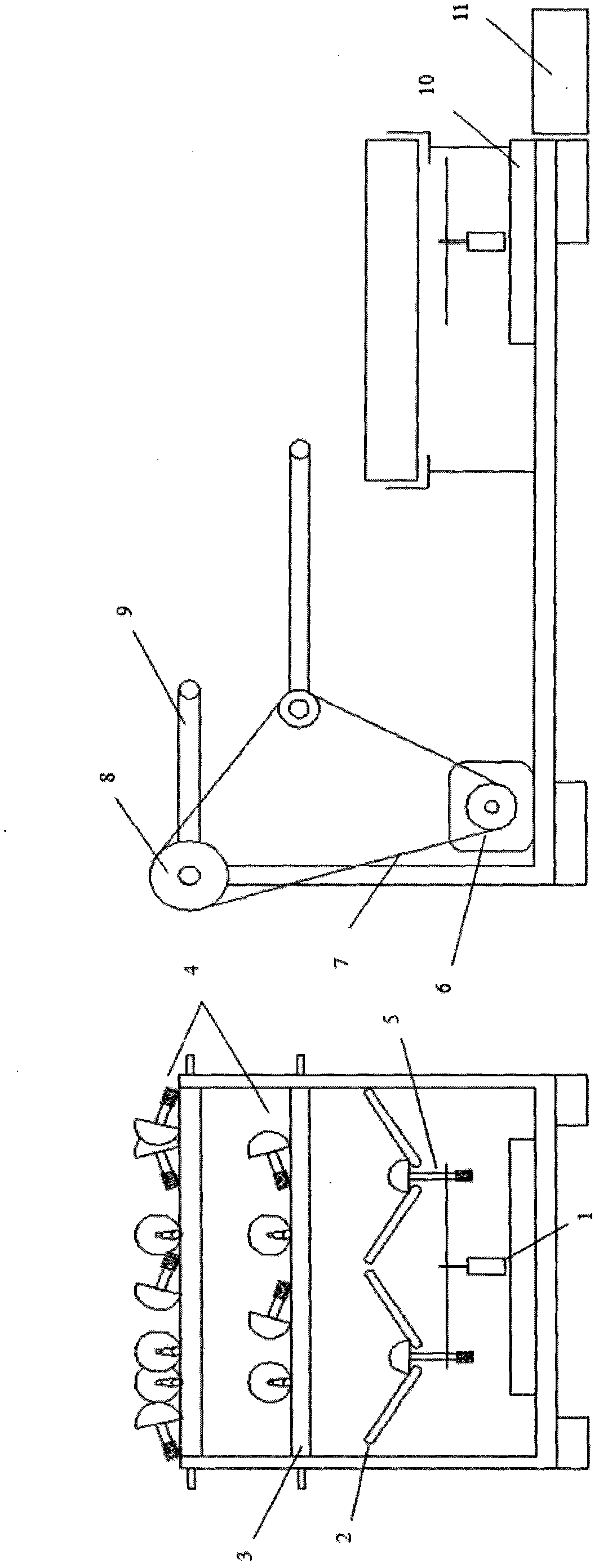

[0009] As attached to the manual figure 2 Shown, by manually picking off from the substratum to be poured into the primary conveyor belt (9), utilize the speed of the primary conveyor belt (9) and the falling distance between the dumping position and the primary conveyor belt, Preliminarily break up the piles of mushrooms. The slider mushroom will fall to the secondary conveyor belt (3) along with the delivery of the primary conveyor belt (9). Utilize the speed difference between the primary conveyor belt (9) and the secondary conveyor belt (3) (assuming that the primary conveyor belt speed is v1, and the secondary conveyor belt speed is v2, so that v1

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap