Double-rolling brush type seedling trimming mechanism configured on solanaceae automatic grafting machine

An automatic grafting and double-rolling brush technology, which is applied in the direction of agricultural machinery and tools, cutting tools, cutting equipment, etc., can solve the problem of affecting the accuracy of the clamping position of the grafting machine, reducing the quality of clamping and grafting operations, and hindering the clamping operation and other problems, to achieve the effect of reducing grafting failure, simple and reasonable structure, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

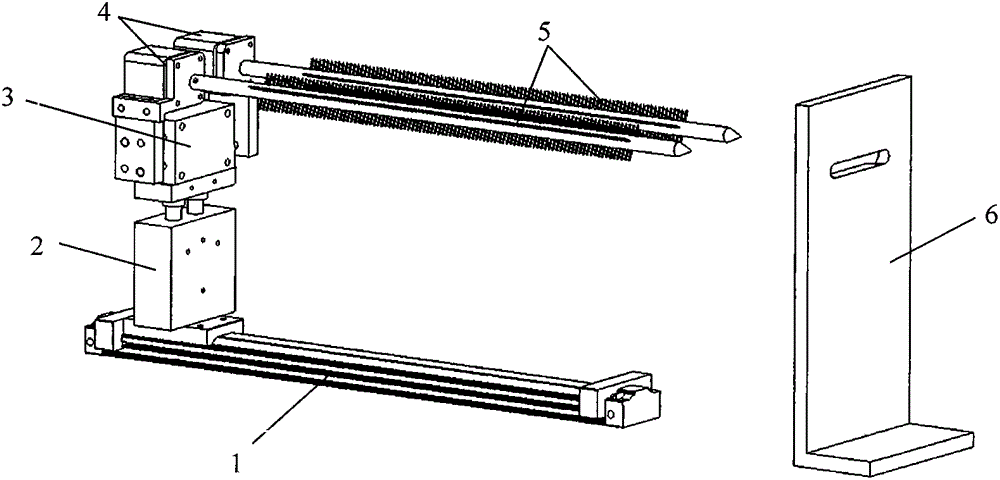

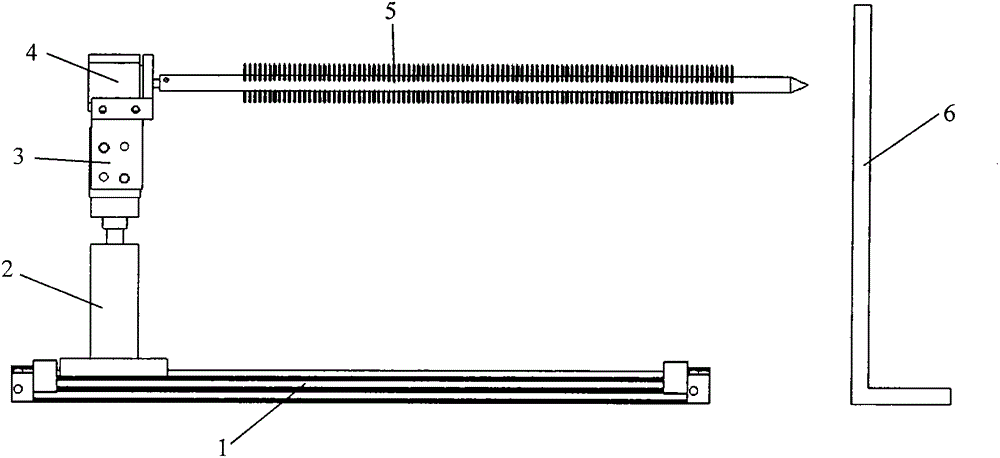

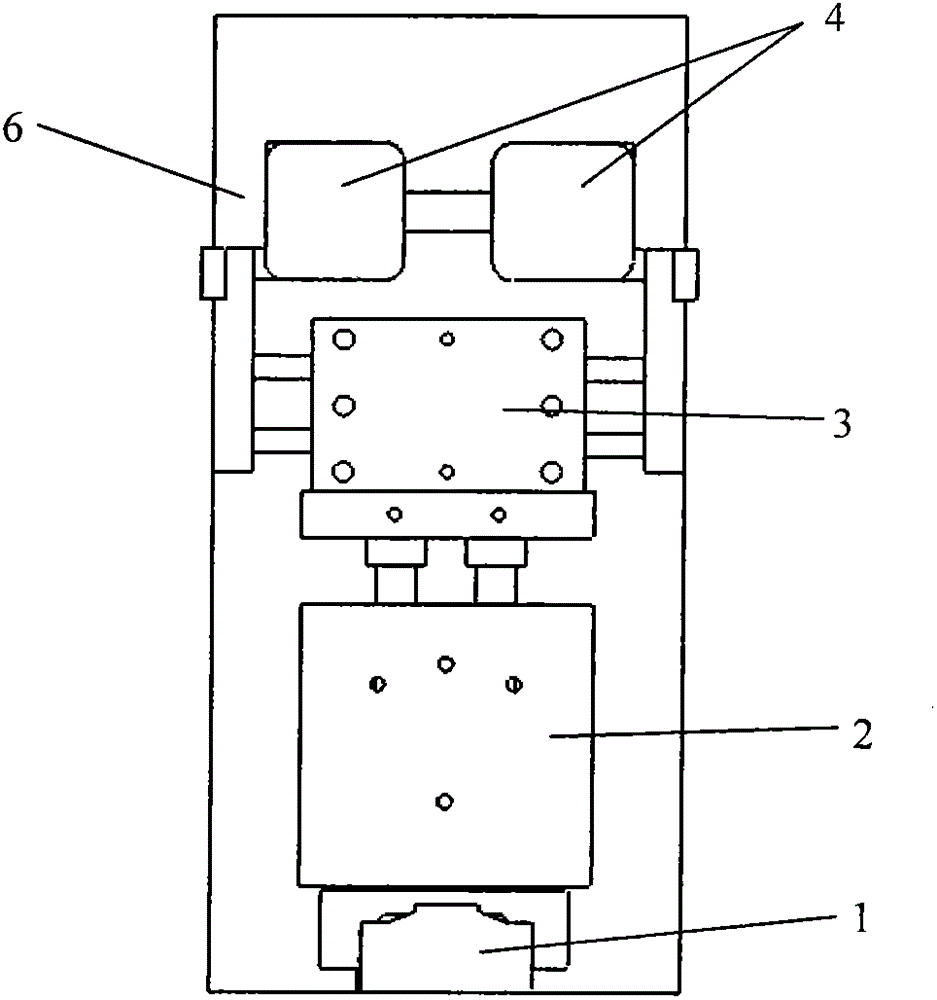

[0013] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A double-rolling brush-type seedling trimming mechanism configured on the Solanaceae automatic grafting machine, the height position adjustment motion assembly 2 is fixed on the longitudinal insertion motion assembly 1, and the horizontal distance adjustment motion assembly 3 is equipped with the height position adjustment motion On the assembly 2, the motors 4 are respectively installed on the laterally opposite sides of the lateral spacing adjustment motion assembly 3, and the two axial brush rollers 5 are parallel to each other and are mounted on the motors 4 on both sides in a horizontal cantilever structure. A support pallet 6 with a strip-shaped slideway support hole is configured at the outer parts of the cantilever ends of the two shaft-type rolling brush rollers 5. The slideway support holes are either fitted into the support or disengaged. The lo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap