Cellulase separation and purification method

A technology of cellulase and purification methods, applied in the direction of microorganism-based methods, biochemical equipment and methods, enzymes, etc., can solve the problems of bacterial growth, cellulase enzyme activity inactivation, and cellulase enzyme activity. and other problems, to achieve the effect of improving the yield of enzyme activity and solving the effect of enzyme inactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

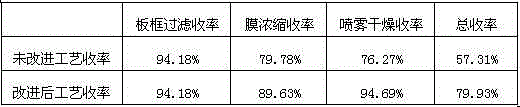

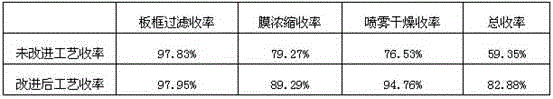

Embodiment 1

[0016] Embodiment 1: Utilize Trichoderma reesei to ferment and produce cellulase, 500L fermentation tank liquid volume 400L ferments 6 days and finish; Measure the FPA enzymatic activity of wherein cellulase is 46.2U / ml, measuring method is People's Republic of China light industry Industry standard QB 2583-2003; plate and frame filter to remove large particles and mycelia in the fermentation broth to obtain 380L of fermentation broth, filtrate FPA enzyme activity 45.8U / ml; plate and frame filtrate is pumped into a low-temperature storage tank and cooled with 4°C cooling water It is circulated cold and stored below 15°C; the plate and frame filtrate is concentrated to 800U / ml through a 30KD ultrafiltration membrane, which takes 3 days, and the volume of the concentrated solution is 19.5L; 39g (0.2%, w / v) lactose is added to the concentrated solution Mix with 97.5g (0.5%, w / v) of silicon dioxide, stir evenly, and the mixed material passes through the PALL sterilization eq

Embodiment 2

[0018] Embodiment 2: Utilize Trichoderma reesei to ferment and produce cellulase, 500L fermenting tank liquid capacity 400L ferment 6 days and finish; Measure wherein the FPA enzyme activity of cellulase is 46.2U / ml, measuring method is People's Republic of China light industry Industry standard QB 2583-2003; plate and frame filter to remove large particles and mycelia in the fermentation broth to obtain 380L of fermentation broth, filtrate FPA enzyme activity 45.8U / ml; plate and frame filtrate is pumped into a low-temperature storage tank and cooled with 4°C cooling water It is circulated cold and stored below 15°C; the plate and frame filtrate is concentrated to 700U / ml through a 30KD ultrafiltration membrane, which takes 3 days, and the volume of the concentrated solution is 19.5L; 39g (0.2%, w / v) lactose is added to the concentrated solution Mix with 97.5g (0.5%, w / v) of silicon dioxide, stir evenly, and the mixed material passes through the PALL sterilization equipm

Embodiment 3

[0019] Embodiment 3: Utilize Trichoderma reesei to ferment and produce cellulase, 500L fermenting tank liquid capacity 400L ferment 6 days and finish; Measure wherein the FPA enzyme activity of cellulase is 46.2U / ml, measuring method is People's Republic of China light industry Industry standard QB 2583-2003; plate and frame filter to remove large particles and mycelia in the fermentation broth to obtain 380L of fermentation broth, filtrate FPA enzyme activity 45.8U / ml; plate and frame filtrate is pumped into a low-temperature storage tank and cooled with 4°C cooling water It is circulated cold and stored below 15°C; the plate and frame filtrate is concentrated to 600U / ml through a 30KD ultrafiltration membrane, which takes 3 days, and the volume of the concentrated solution is 19.5L; 39g (0.2%, w / v) lactose is added to the concentrated solution Mix with 97.5g (0.5%, w / v) of silicon dioxide, stir evenly, and the mixed material passes through the PALL sterilization equipm

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap