Synthetic method of N-ethyl ethylenediamine

A technique for the synthesis of ethylethylenediamine, which is applied in the direction of condensation/addition reaction to prepare amino compounds, organic chemistry, etc., can solve the problems of expensive catalyst, harsh reaction conditions, and difficulty in purification, and achieve low production cost and easy Effect of purification and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

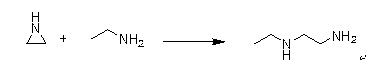

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in combination with specific embodiments.

[0030] The whole reaction was carried out in a closed autoclave. 150 g of ethylamine aqueous solution (the content of ethylamine was calculated as 105 g), 100.3 g of cycloethylamine and 5 g of molybdenum oxide were added into the autoclave together, the temperature was raised to 50 ° C, and the reaction was stirred for 5 h. After the reaction is completed, molecular sieves are added to the reaction liquid to seal and dry the liquid. The next day, the molecular sieves were filtered off, and the filtrate was distilled under reduced pressure by a water pump. The fraction at 38-41°C was collected and weighed to obtain 196g, with a purity of 99% and a yield of 95.6%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap