Preparation method of environment-friendly economic luminescent carbon quantum dot

A technology of carbon quantum dots and fluorescence, which is applied in the fields of nanomaterials and biomedical engineering, can solve the problems that limit the large-scale production and practical application of fluorescent carbon quantum dots, complex follow-up processing methods, expensive raw materials, etc., and achieve small steric hindrance, The effect of simple preparation process equipment and high optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

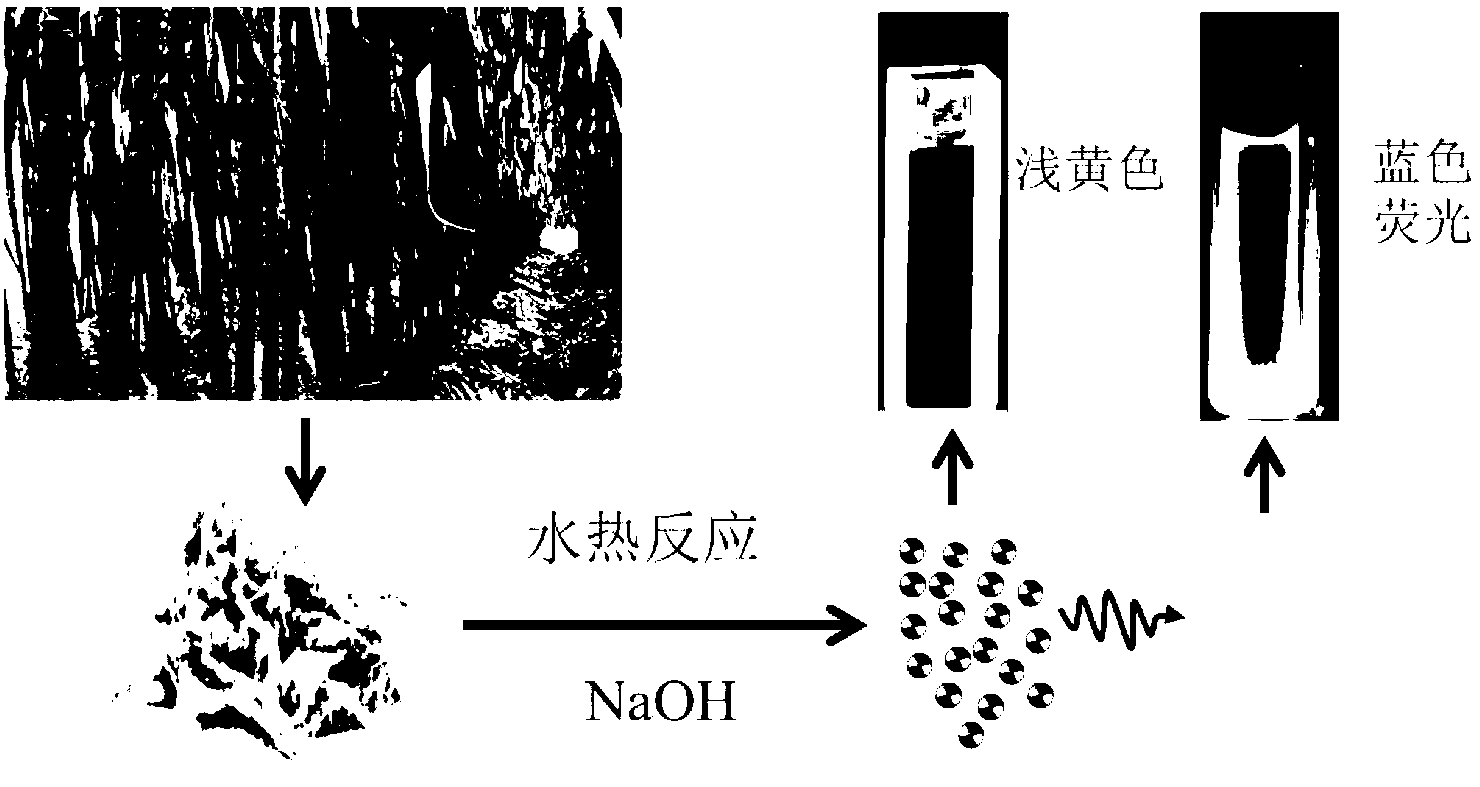

[0034] Example 1: Weigh 1 g of bagasse and add it to 20 ml of double distilled water. The reaction solution was put into a stainless steel reaction kettle lined with 50ml PTFE, heated in an electric oven at a constant temperature of 180°C for 1h to obtain a light yellow solution containing carbon quantum dots. After the solution is naturally cooled, filter with medium-speed filter paper to remove insoluble black precipitates, centrifuge at 15000g to remove large particles, collect the supernatant and inject it into a dialysis bag with a molecular cut-off of 1000Da for dialysis. The dialysis time is 72h, and it is changed every 12h. water. The dialysis product was subjected to rotary evaporation to obtain a concentrated solution. The concentrated solution was freeze-dried to powder at -50°C with a yield of 0%.

Example Embodiment

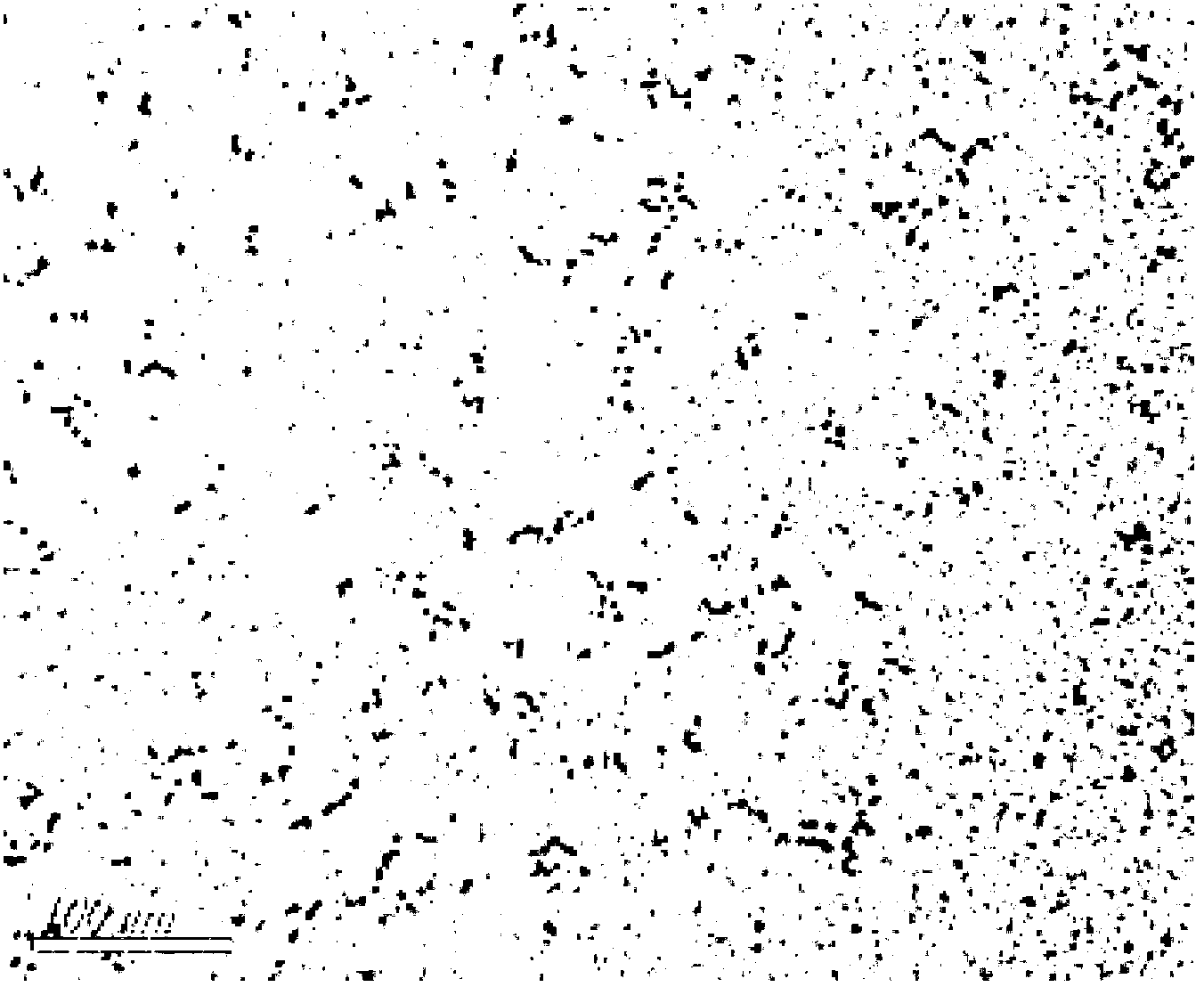

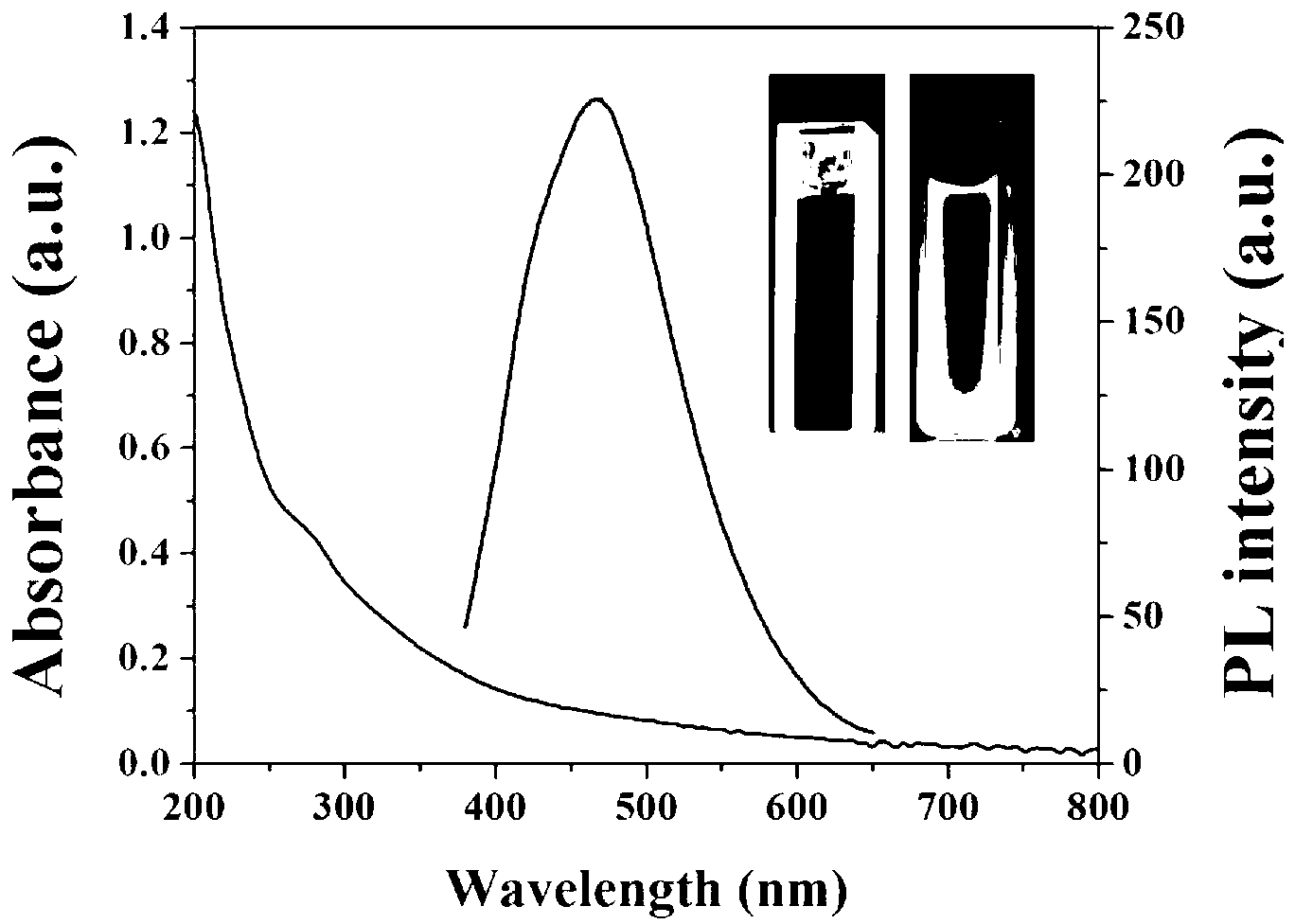

[0035] Example 2: Weigh 1g of bagasse and add it to 20ml of 0.6M sodium hydroxide aqueous solution. The reaction solution was put into a stainless steel reaction kettle lined with 50ml PTFE, heated in an electric oven at a constant temperature of 180°C for 1h to obtain a light yellow solution containing carbon quantum dots. After the solution is naturally cooled, filter with medium-speed filter paper to remove insoluble black precipitates, centrifuge at 15000g to remove large particles, collect the supernatant and inject it into a dialysis bag with a molecular cut-off of 1000Da for dialysis. The dialysis time is 72h, and it is changed every 12h. water. The dialysis product was subjected to rotary evaporation to obtain a concentrated solution. The concentrated solution was freeze-dried to powder at -50°C to obtain carbon quantum dots with high fluorescence performance. The yield was 2.17%.

Example Embodiment

[0036] Example 3: Weigh 1g of bagasse and add it to 20ml of 0.8M sodium hydroxide aqueous solution. The reaction solution was put into a stainless steel reaction kettle lined with 50ml PTFE, heated in an electric oven at a constant temperature of 180°C for 2h to obtain a light yellow solution containing carbon quantum dots. After the solution is naturally cooled, filter with medium-speed filter paper to remove insoluble black precipitates, centrifuge at 15000g to remove large particles, collect the supernatant and inject it into a dialysis bag with a molecular cut-off of 1000Da for dialysis. The dialysis time is 72h, and it is changed every 12h. water. The dialysis product was subjected to rotary evaporation to obtain a concentrated solution. The concentrated solution was freeze-dried to powder at -50°C to obtain carbon quantum dots with high fluorescence performance, with a yield of 3.24%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap