Self-induction-type liquid crystal display stripping structure

A liquid crystal screen, adhesive layer technology, applied in optics, lamination auxiliary operations, instruments, etc., can solve the problems of low yield, scrap, easy to damage liquid crystal display units, etc., to improve product yield, easy to peel, easy to operate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

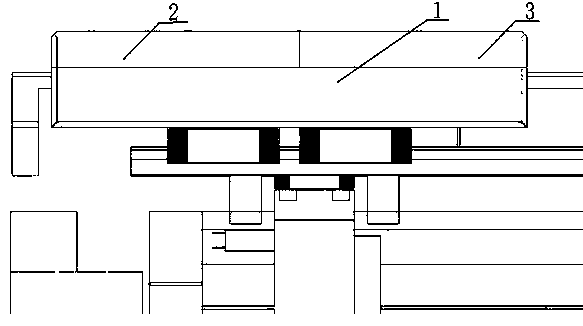

[0015] As one of the best embodiments of the stripping structure of a self-inductive liquid crystal screen of the present invention comprising a stripping platform, see the attached figure 1 An electric heating element 2 is arranged on the peeling platform 1, an adhesive layer softening detection device 3 is arranged on the peeling platform 1, and a main control circuit is connected to the electric heating element 2 and the adhesive layer softening detection device 3.

[0016] The adhesive layer softening detection device 3 is also connected with a peeling force detection and feedback device.

[0017] The structural design of the present invention separates the peeling mechanism from the previous translation and alignment mechanism, and is suitable for self-inductive peeling, that is, automatically selects the most suitable peeling timing in the heating process, and can adjust the peeling force according to different products and other factors. . In addition, during the heating

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap