Sewage treatment system for printing plant

A technology of sewage treatment system and printing workshop, which is applied in the field of sewage treatment system of printing workshop, which can solve the problems of environmental pollution, toxicity, and great environmental impact, and achieve the effects of saving water resources, good filtering effect and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

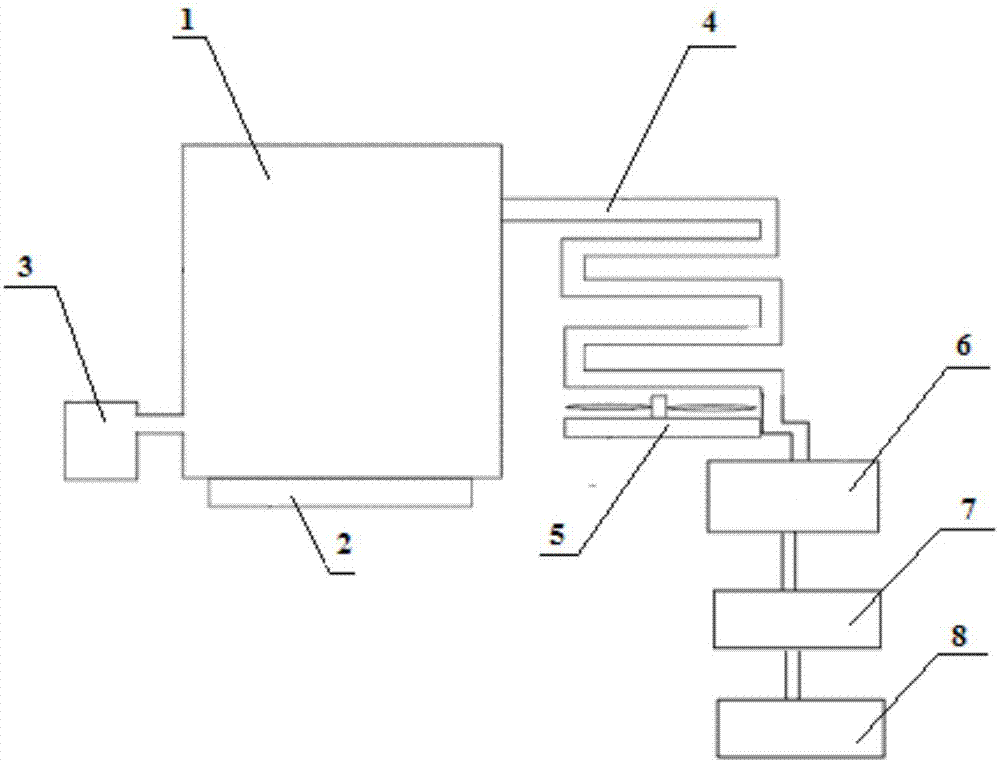

[0013] Such as figure 1 As shown, a sewage treatment system for a printing workshop includes a distillation tank 1, an electric heater 2 is provided at the bottom of the distillation tank 1, an antifoaming agent storage tank 3 communicates with the distillation tank 1, and a condensation pipe 4 One end is connected to the top of the distillation tank 1, and the other end is connected to the oil-water separator 6. The condensation pipe 4 is provided with a cooling device 5, and the oil-water separator 6 is connected to the sand filter 7 and the anaerobic hydrolysis tank 8 in turn. The cooling device 5 is a cooling fan. Filter sand is laid in the sand filter tank 7 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap