Drum-type carbon black ozonation retort

An ozone oxidation and reaction tank technology, which is applied in chemical instruments and methods, chemical/physical processes, fibrous fillers, etc., can solve the problems of possible accumulation above the baffle, tall equipment, dead beds, etc., which is conducive to safe production, The quality is uniform and stable, which is conducive to the effect of equipment maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

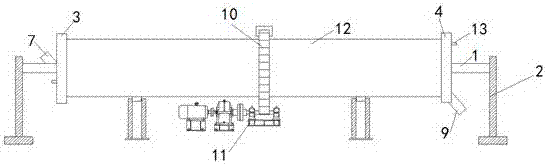

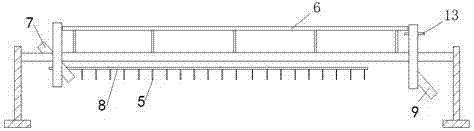

[0025] A drum-type carbon black ozone oxidation reaction tank, including a bracket 2 and a tank body 12, the tank body is fixed on the brackets 2 at both ends through a fixed shaft 1 that forms a certain angle with the horizontal direction, and the two end faces of the reaction tank 3 , 4 is fixed relative to the fixed shaft 1, and the two ends of the tank body are dynamically sealed with the two end faces; the end face 3 on one side of the tank body is provided with a granular carbon black feed pipe 7 at a certain angle, which communicates with the tank body; A closed-ended ozone gas delivery main pipe 8 extends into the tank; the ozone gas delivery main pipe is connected with a plurality of branch pipes 5, and there are a number of air delivery micropores all over the relative movement surface of the material at the end of the branch pi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap