Sacrificial anode core breaking detection system and method based on passing eddy current

A sacrificial anode and detection system technology, applied in the direction of material magnetic variables, etc., can solve the problem of consuming the detection cycle of the material to be inspected, and achieve the effects of accurate and precise testing, efficient detection, and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment

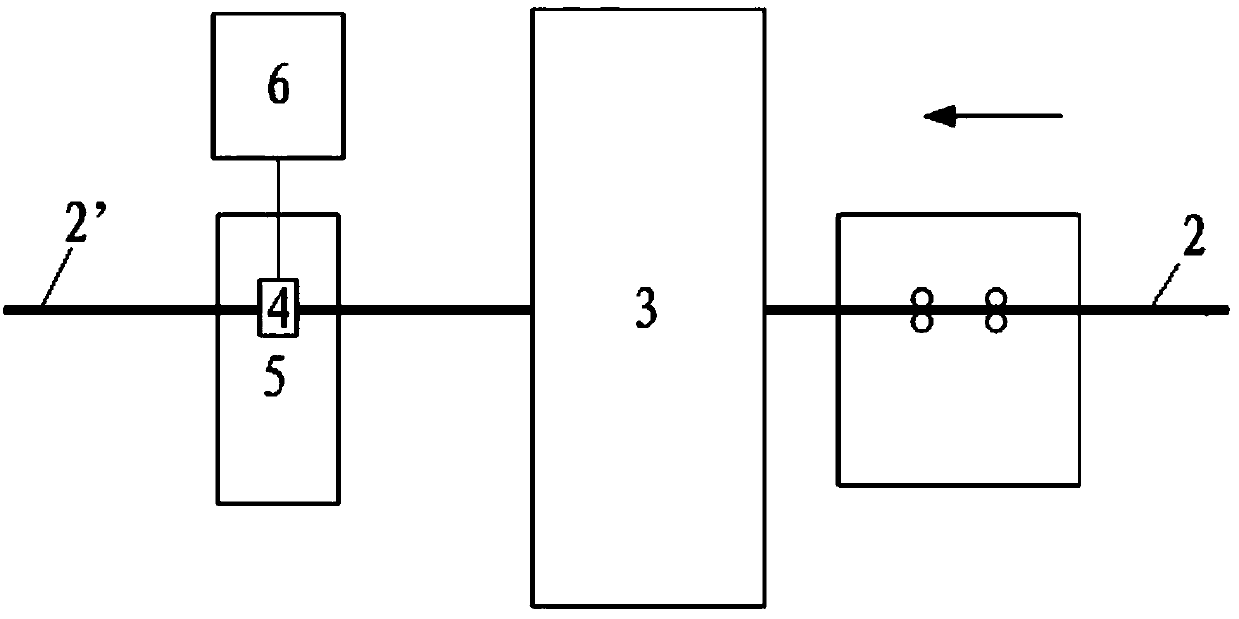

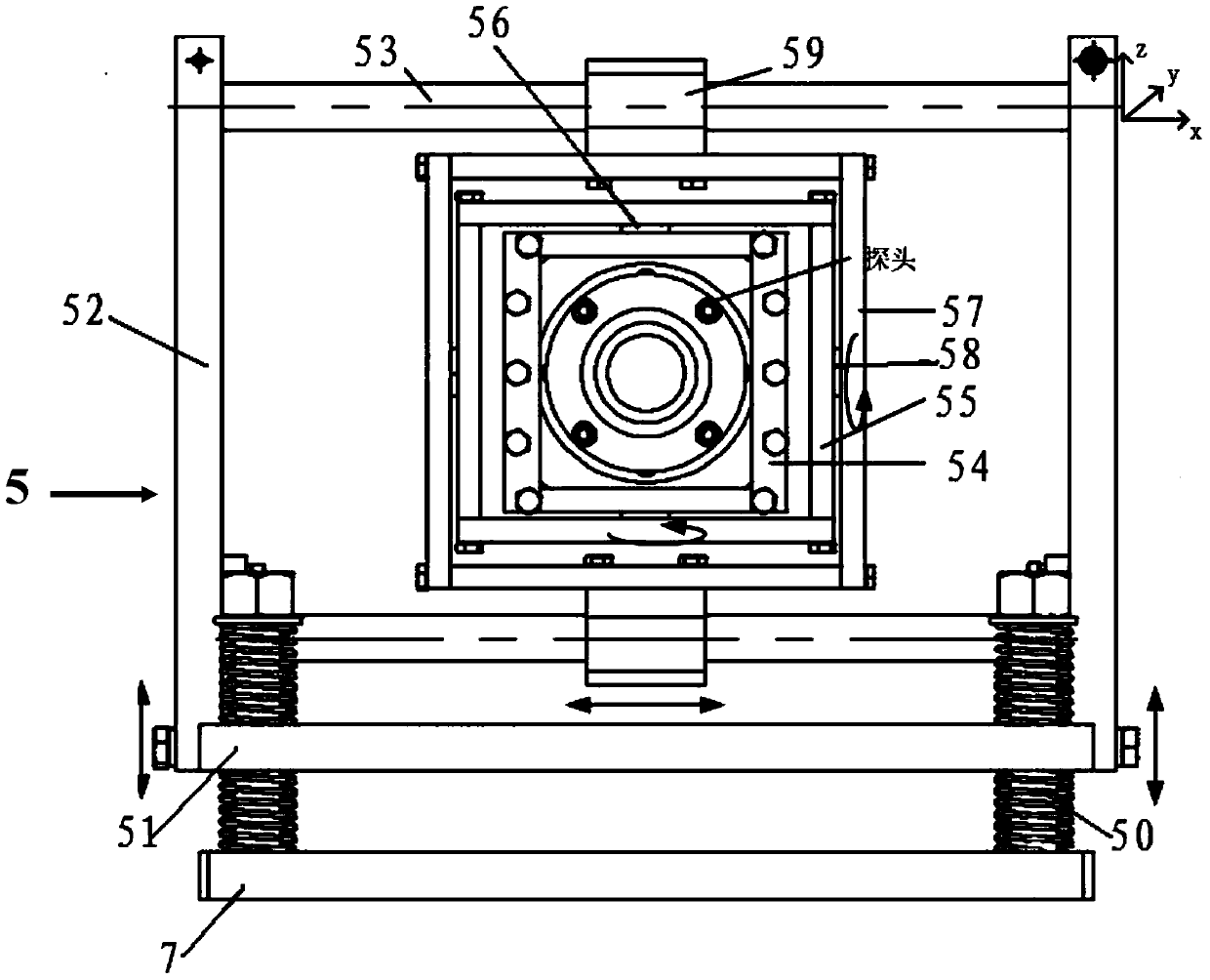

[0055] The following is a specific embodiment of the present invention: take the detection of a diamond-shaped extruded zinc anode strip of 16×22 mm as an example.

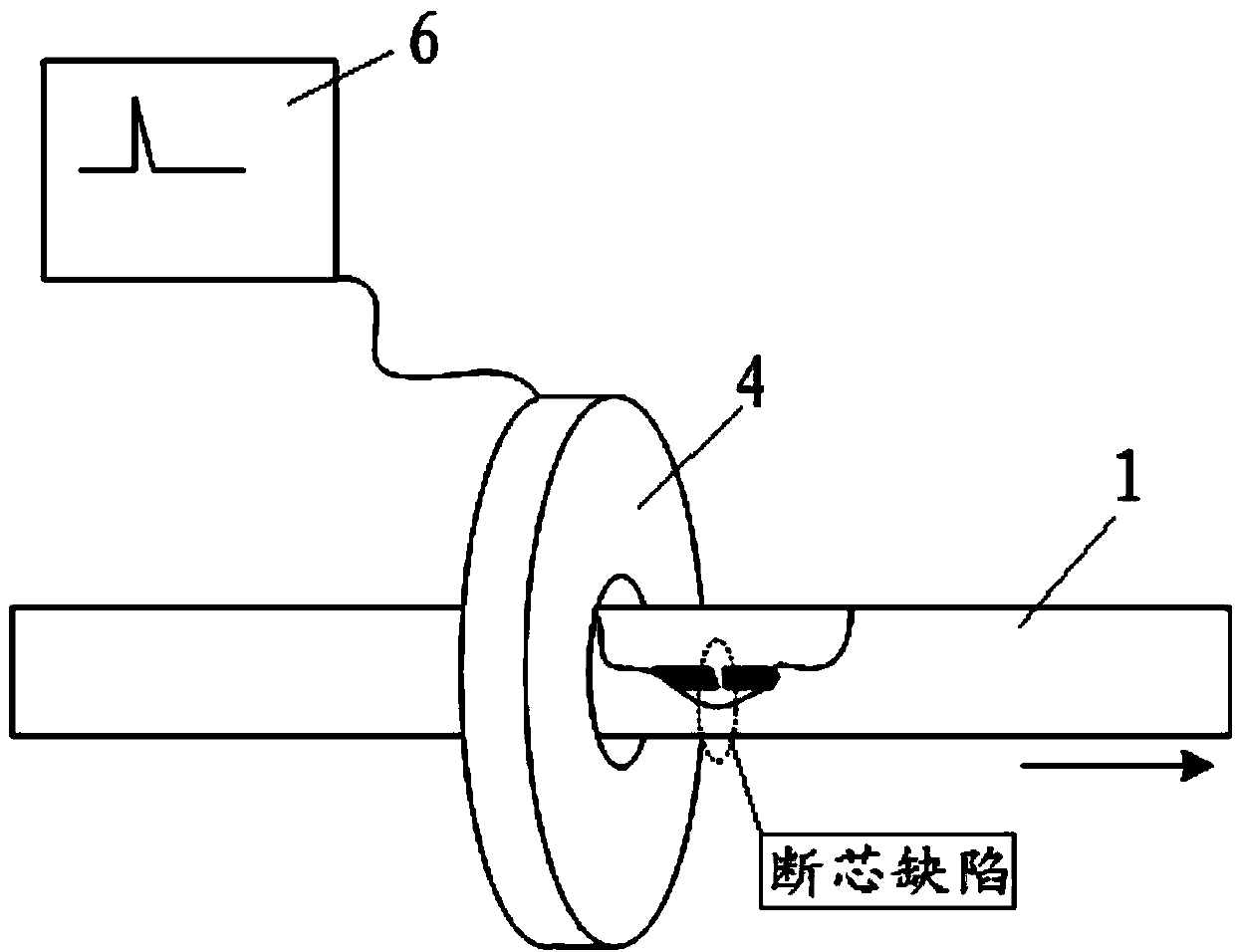

[0056] This type of extruded zinc anode is strip-shaped, its cross-section is diamond-shaped, and its size conforms to the national standard GB / T17848-1999. The tested sacrificial anode sample is type B, with a long axis of 22.23 mm, a short axis of 15.88 mm, a length of about 1 m, and a broken core defect in the middle.

[0057] First, process an artificial defect at the iron core at the end (drill a hole along the axial direction, the diameter of the hole is 1mm, and the depth is 30mm). Since the thickness of the high-purity zinc coated outside the iron core of this type of anode is relatively large, the selected A lower frequency should be selected when detecting the frequency. Here, 4kHz is selected as the detection frequency. Whether the detection frequency meets the detection requirements can be verified by

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap