Aluminum heat exchanger pipeline of which inner wall is provided with anticorrosive coating and processing method of aluminum heat exchanger pipeline

A technology of anti-corrosion coating and exchanger tube, which is applied in the direction of coating, pretreatment surface, and device for coating liquid on the surface, etc., which can solve the problems of water leakage failure of aluminum heat exchanger, reduction of product service life, and corrosion of aluminum heat exchanger and other problems, to achieve the effect of preventing pipeline corrosion and perforation, prolonging service life and preventing pipeline from being corroded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

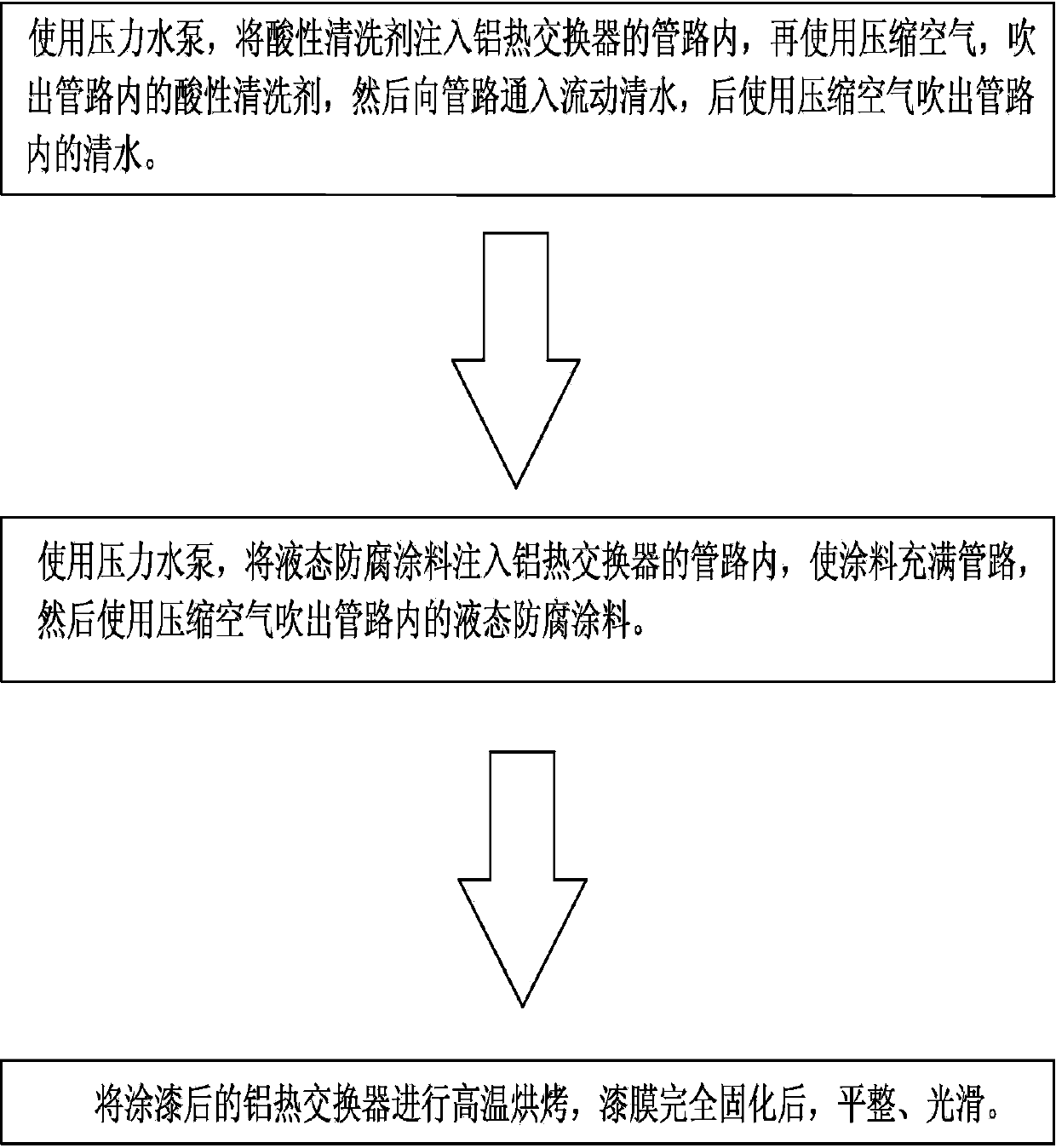

[0019] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: An aluminum heat exchanger pipeline with an anti-corrosion coating on the inner wall is provided with an anti-corrosion coating made of liquid paint on the inner wall of the pipeline. The liquid paint can be water-based paint or oil-based paint. The liquid paint in this embodiment is Water based paint. The processing method of the above-mentioned pipeline sequentially includes the steps of pre-treatment, painting in the pipe, and curing, and the details are as follows:

[0020] Step 1: Pre-treatment (chemical cleaning).

[0021] 1. Use a pressure pump to inject the acid cleaning agent (mixed acid solution, the main components are hydrofluoric acid, sulfuric acid, nitric acid, surfactant, etc.) from one end of the aluminum heat exchanger pipeline, and flow out from the other end, and use the pressure after the outflow. The water pump continues to maintain a circulating flow time of 1 to 3 minutes, so that the cleaning agen

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap