Fixing device for detecting fabric freezing resistance and application method thereof

A fixing device and anti-icing technology, which is applied in the direction of measuring device, workpiece clamping device, and material absorption weighing, etc., can solve the problems of poor consistency, affecting the detection result, and occupying a large number of people, etc., so as to achieve simple and convenient use carrying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Semi-quantitatively detect the surface moisture resistance of fabric A and fabric B;

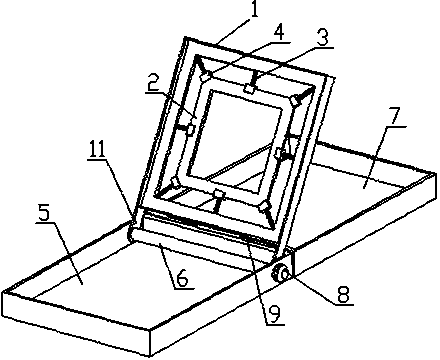

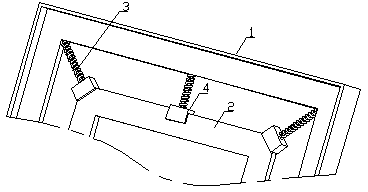

[0062] The device used to semi-quantitatively detect the surface moisture resistance of the fabric is selected: the size specification of the outer steel frame 1 is: 13.2cm × 12cm, the length of the two extended shaft frames 11 is 0.8cm, and the size of the inner steel frame 2 The specifications are: 11cm×10cm, the inner steel frame 2 is connected to the outer steel frame 1 through 8 springs 3; the first water collection tank 5 and the second water collection tank 7 are two rectangular water tanks, length 14cm×width 12cm×depth 5cm , there is a baffle and a link between the two rectangular water tanks.

[0063] The process of using the device and method to semi-quantitatively detect the surface moisture resistance of fabric A includes:

[0064] The first step, first, fix the 11cm×10cm fabric A on the inner steel frame 2 on the fabric fixing spring plate with the fabric card 4;

[0065]

Embodiment 2

[0076] Semi-quantitatively detect the water permeability of fabric C and fabric D;

[0077] The device used for the semi-quantitative detection of the water seepage resistance of the fabric is selected: the fabric fixed spring plate is composed of 2 connected equal-proportion rectangular steel frames, and the size of the outer steel frame 1 is: 28.8cm×24cm, and 2 extend out The shaft frame 11 has a length of 1.2cm, and the size specification of the inner steel frame 2 is: 24cm×20cm. The inner steel frame 2 is connected to the outer steel frame 1 through 4 springs; the first water collection tank 5 and the second water collection tank 7 are respectively It is two rectangular water tanks, the size specifications are: length 30cm x width 24cm x depth 10cm, there are baffles and link parts between the two rectangular water tanks;

[0078] The process of using the device to semi-quantitatively detect the water permeability of fabric C includes:

[0079] First, fix the 24cm×20cm fabri

Embodiment 3

[0090] Semi-quantitatively detect the anti-icing performance of fabric E and fabric F;

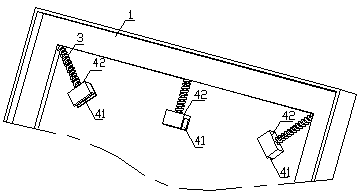

[0091] The device used for testing the anti-icing property of the fabric E in low temperature environment: the size specification of the outer steel frame 1 is: 66cm×50cm, the length of the two extended axle frames 11 is 4cm, and the size specification of the inner steel frame 2 is: 40cm×30cm, the inner steel frame 2 is connected to the large rectangular steel frame through 8 springs; the first water collection tank 5 and the second water collection tank 7 are two rectangular water tanks respectively, and the dimensions are: length 70cm×width 50cm× 20cm deep, there is a baffle and a link between the two rectangular sinks;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap