Three-direction displacement cargo transfer robot

A handling robot, three-direction displacement technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as cargo drop and mounting seat falling off, and achieve the effect of strengthening firmness, improving stability and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0018] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention can be more clearly defined.

[0019] The present invention provides a three-direction displacement cargo handling robot.

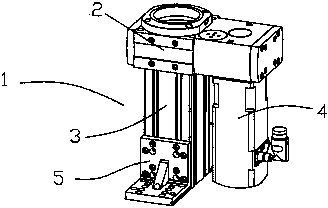

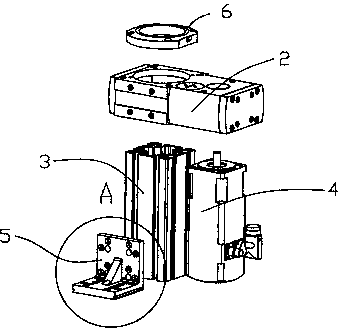

[0020] like Figure 1 to Figure 4 As shown, the three-direction displacement cargo handling robot 1 of the present invention includes a longitudinally arranged guide column 3, the bottom of the guide column 3 is provided with a pair of detachable fixing projections 5, and the top of the guide column 3 is provided with a connecting portion 2, the connecting portion 2 is provided with a detachable drive unit 4 .

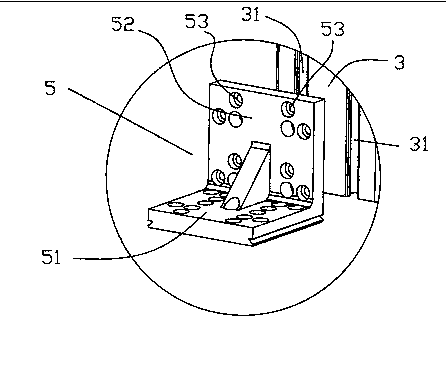

[0021] A pair of guide transverse grooves 31 are formed on the side wall of the guide column 3 , and the fixing protrusion 5 includes a first fixi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap