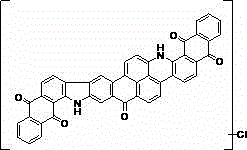

Vat olive MW dye with low heavy metal and preparation method of vat olive MW dye

A low-heavy metal and olive technology, applied in the direction of anthracene dyes, organic dyes, chemical instruments and methods, etc., can solve the problems of serious environmental impact, high wastewater concentration, poor effect, etc., achieve low heavy metal content, reduce heavy metal content, various Excellent item fastness performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of low heavy metal reduced olive MW dyes

[0031] a. Preparation of reduced olive MW: the chlorination pot uses jacketed hot oil to bake the pot to ensure that there is no water in the pot; add 1400kg aluminum trichloride and 300kg sodium chloride into the chlorination pot, stir evenly, and heat up to 150 ℃, heat preservation for 3 hours, after the heat preservation is over, close the hot oil circulation system, open the cold oil system to cool down the chlorination pot, cool down to 105 ℃, close the cold oil system, slowly add 50L chlorosulfonic acid, the addition time is 2 hours, After the addition, heat and stir for 10 minutes, add 150 kg of olive T raw powder, heat to 150 ° C, and keep warm for 3 hours to obtain reduced olive MW dye;

[0032] b. Add the above-mentioned reduced olive MW dye into an enamel kettle containing acidified bottom water consisting of 150L of 31% hydrochloric acid, 25L of 98% sulfuric acid and 3000L of water, beat for 3 hours, heat t

Embodiment 2

[0035] Preparation of low heavy metal reduced olive MW dyes

[0036] a. Preparation of reduced olive MW: the chlorination pot uses jacketed hot oil to bake the pot to ensure that there is no moisture in the pot; add 1650kg aluminum trichloride and 375kg sodium chloride into the chlorination pot, stir evenly, and heat up to 160°C , heat preservation for 4 hours, after the heat preservation is over, close the hot oil circulation system, open the cold oil system to cool down the chlorination pot, cool down to 110°C, close the cold oil system, slowly add 60L chlorosulfonic acid, the addition time is 2.5 hours, add After that, heat and stir for 10 minutes, add 150kg of olive T raw powder, heat to 160°C, and keep warm for 3 hours to obtain reduced olive MW dye;

[0037] b. Add the above-mentioned reduced olive MW dye into an enamel kettle containing acidified bottom water consisting of 165L of 38% hydrochloric acid, 55L of 98% sulfuric acid and 3000L of water, beat for 3 hours, heat to

Embodiment 3

[0040] Preparation of low heavy metal reduced olive MW dyes

[0041] a. Preparation of reduced olive MW: use jacketed hot oil to bake the chlorination pot to ensure that there is no water in the pot; add 1800kg aluminum trichloride and 600kg sodium chloride into the chlorination pot, stir evenly, and heat up to 165°C , heat preservation for 4 hours, after the heat preservation is over, close the hot oil circulation system, open the cold oil system to cool down the chlorination pot, cool down to 110°C, close the cold oil system, slowly add 75L chlorosulfonic acid, the addition time is 2.5 hours, add After that, heat and stir for 10 minutes, add 150 kg of olive T raw powder, heat to 170 ° C, and keep warm for 3 hours to obtain reduced olive MW dye;

[0042] b. Add the above-mentioned reduced olive MW dye into an enamel kettle containing acidified bottom water consisting of 200L of 38% hydrochloric acid, 80L of 98% sulfuric acid and 3000L of water, beat for 3 hours, heat to 80°C, an

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap