Nano densified polymer-based waterproof coating and preparation method thereof

A waterproof coating and polymer technology, applied in the field of waterproof coatings, can solve the problems of affecting the waterproof function, curling and shrinking of molecular chains, deterioration of the compactness of the waterproof layer, etc., so as to improve waterproof performance, improve uniformity, and improve availability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

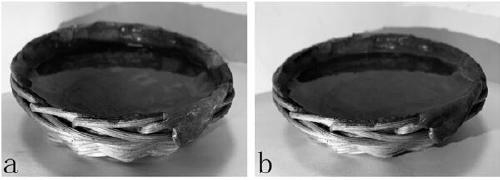

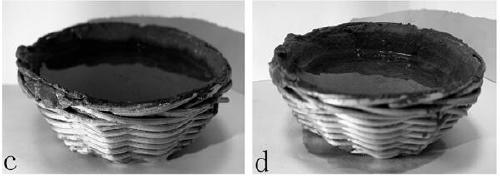

Image

Examples

Embodiment 1

[0033] (1) Dissolve aluminum trichloride in water first, then add nano zeolite powder to disperse evenly, make aluminum trichloride reside in the micropores of nano zeolite powder, then filter and dry to obtain aluminum trichloride / zeolite powder Composite material; the drying temperature is 128°C and the drying time is 2.5h;

[0034] The ratio of each raw material is, in parts by weight, 7 parts by weight of aluminum trichloride, 30 parts by weight of water, and 15 parts by weight of zeolite powder;

[0035] (2) First put the aluminum trichloride / zeolite powder composite material obtained in step (1) into a ball mill, then perform ball milling, then add polyvinyl alcohol and a small amount of water, and continue to stir evenly to obtain polyvinyl alcohol-coated three Aluminum chloride / zeolite powder composite material; the speed of ball milling treatment is 25r / min, the temperature is 86°C, and the time is 34min; the time for continuous stirring is 16min;

[0036] The rat

Embodiment 2

[0040] (1) Dissolve aluminum trichloride in water first, then add nano zeolite powder to disperse evenly, so that aluminum trichloride resides in the micropores of nano zeolite powder, then filter and dry to obtain aluminum trichloride / zeolite powder Composite material; the drying temperature is 125°C and the drying time is 3h;

[0041] The ratio of each raw material is, in parts by weight, 6 parts by weight of aluminum trichloride, 35 parts by weight of water, and 18 parts by weight of zeolite powder;

[0042] (2) First put the aluminum trichloride / zeolite powder composite material obtained in step (1) into a ball mill, then perform ball milling, then add polyvinyl alcohol and a small amount of water, and continue to stir evenly to obtain polyvinyl alcohol-coated three Aluminum chloride / zeolite powder composite material; the speed of ball milling treatment is 25r / min, the temperature is 82°C, and the time is 38min; the time for continuous stirring is 12min;

[0043] The

Embodiment 3

[0047] (1) Dissolve aluminum trichloride in water first, then add nano zeolite powder to disperse evenly, so that aluminum trichloride resides in the micropores of nano zeolite powder, then filter and dry to obtain aluminum trichloride / zeolite powder Composite material; the drying temperature is 135°C, and the drying time is 2h;

[0048] The ratio of each raw material is, in parts by weight, 9 parts by weight of aluminum trichloride, 30 parts by weight of water, and 15 parts by weight of zeolite powder;

[0049] (2) First put the aluminum trichloride / zeolite powder composite material obtained in step (1) into a ball mill, then perform ball milling, then add polyvinyl alcohol and a small amount of water, and continue to stir evenly to obtain polyvinyl alcohol-coated three Aluminum chloride / zeolite powder composite material; the speed of ball milling treatment is 27r / min, the temperature is 88°C, and the time is 32min; the time for continuous stirring is 18min;

[0050] Th

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap