High-temperature axial loading stress corrosion test device

A technology of axial loading and stress corrosion, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problem of solution leakage easily, and achieve the effects of avoiding solution leakage, accurate temperature control and maintaining solution concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] Example

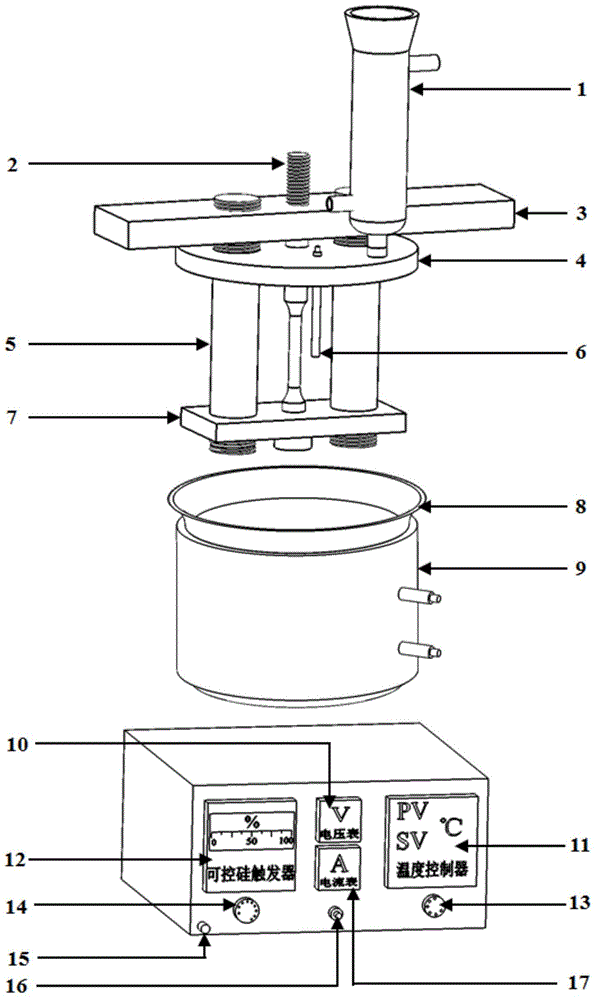

[0026] Such as figure 1 As shown, the high temperature axial load stress corrosion test device of this embodiment includes a load application system and a temperature control system. It is mainly provided with a set of reverse force frames made of Hastelloy, a beaker 8, a stainless steel heating ring 9, and a Teflon closed thermocouple 6, a temperature controller 11, a thyristor trigger 12, a condensate return pipe 1 and a rubber plug 4, the reverse force frame is supported by the reverse force on the upper beam 3 , Reverse force support lower crossbeam 7 and reverse force support column 5, the upper and lower sides of the two reverse force support columns 5 are reverse force support upper crossbeam 3, reverse force support lower crossbeam 7, reverse force support To load sample 2 (rod-shaped). Among them, the upper beam 3 of the reverse force frame is fixed on the two columns of the constant load testing machine or the tensile testing machine, and the sample 6 pe

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap