Submerged-arc welding straight welded pipe diameter expansion outer fan-shaped block for deep sea and surface protection method thereof

A straight seam welded pipe and outer sector technology, which is applied in metal material coating process, fusion spraying, coating and other directions, can solve the problems that the outer sector is not easy to replace, affect the quality of the steel pipe, and wear the outer sector, so as to improve the service life. , The effect of convenient milling processing and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the present invention more clearly and completely, the present invention will be described below in conjunction with specific examples and accompanying drawings.

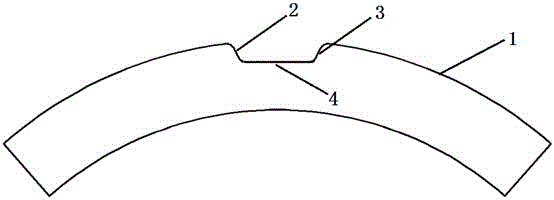

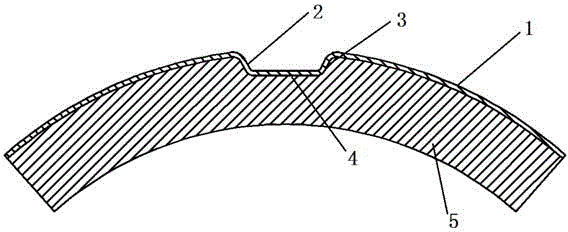

[0027] A U-shaped weld seam accommodation groove is provided outside the fan-shaped middle part of the outer fan-shaped block 1 of the submerged arc welding straight seam welded pipe for deep sea use. The second arc portion 3 and the third arc portion 4 at the bottom form a ternary boride cermet coating 5 on the outer surface of the outer sector block. Preferably, the length of the third arc portion 4 at the bottom of the U-shaped weld receiving groove is 38 mm to 48 mm, and the length of the first arc portion 2 and the second arc portion 3 on both sides is 4.8 mm to 5.9 mm. The included angles between the first arc portion 2 and the third arc portion 4 and between the second arc portion 3 and the third arc portion 4 are all 130° to 140°. The outer sector block is radially divided into a fi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap