Encapsulated bitter peptides, methods of encapsulating bitter peptides, and nutritional compositions including encapsulated bitter peptides

A nutritional composition and a technology for bitter-tasting peptides are applied in the field of encapsulated bitter-tasting peptides, encapsulated bitter-tasting peptides, and nutritional compositions comprising the encapsulated bitter-tasting peptides, and can solve the problem that the composition is difficult to be used orally and unpleasant to hydrolyzed proteins. Taste, inability to achieve biological results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Liposomes were prepared as follows: 1% of phospholipids extracted from soybean or egg was added to water containing 10% by weight of hydrolyzed protein, followed by homogenization. Using Hyprol from Kerry Group TM 3315 as hydrolyzed protein. The tests are detailed in Table 1.

[0082]

[0083] Table 1: Lecithin used in the test

[0084] Particle size distribution analysis demonstrated the formation of liposomes (see Table 2). Each sample homogenized at 200 bars produced a population of aggregates with a particle size distribution ranging from 200-300 nm, characteristic of liposome formation.

[0085] sample name

REF

Top.

Emul.

Met.

Epi.

Eggs

Z-average (d.nm)

288.8

276.6

328.9

284.2

283.1

293.9

PdI

0.254

0.233

0.29

0.251

0.289

0.253

[0086] Table 2: Particle Size Distribution Analysis Test

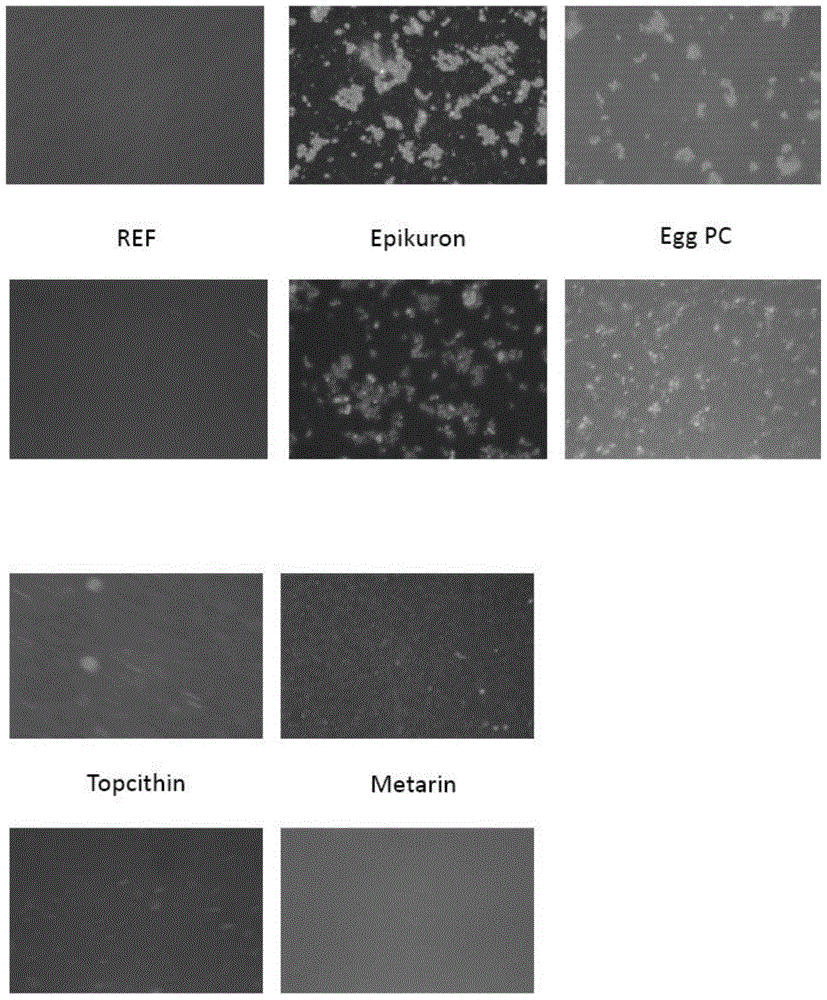

[0087] Such as figure 1 Fluorescence microscopy of lipids stained with N

Embodiment 2

[0090] To ensure migration of bitter peptides into the oil phase of organogels and solid lipid nanoparticles, emulsions were prepared containing oil or melted fat and an aqueous phase in which 10% of Hyprol was dissolved TM 3315. After stirring for 30 minutes, the aqueous and oil phases were separated by decantation. The extracted aqueous phase is then tasted by trained personnel. It must be noted that the extraction step is for evaluation only and should not be used in most embodiments of encapsulated bitter peptides used in nutritional compositions.

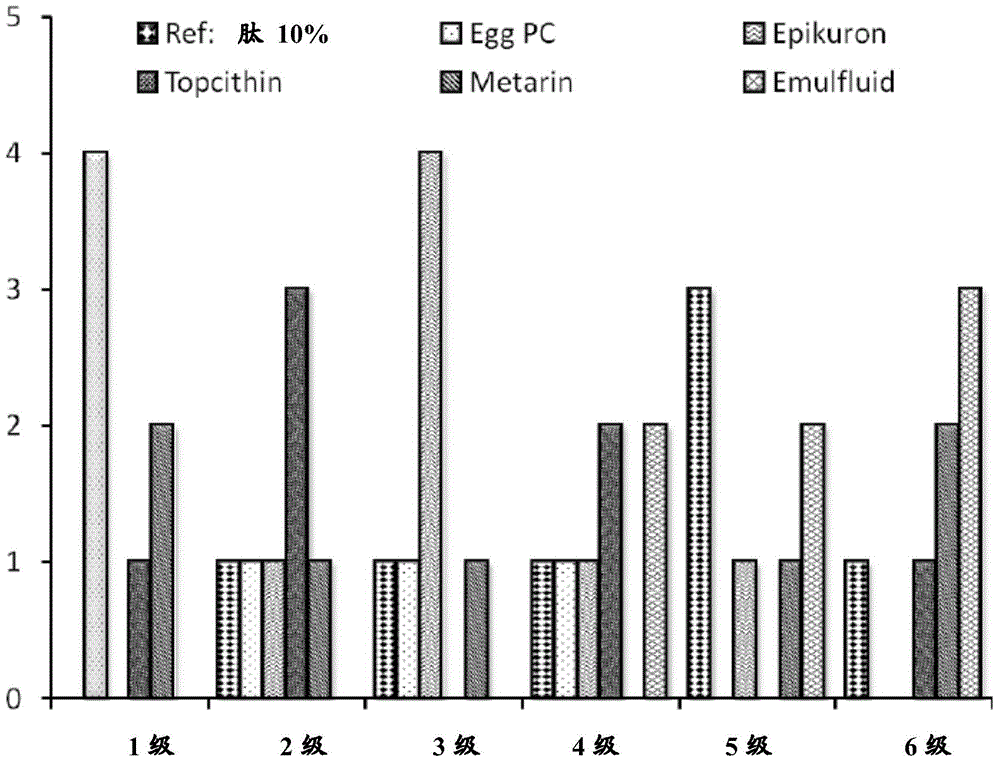

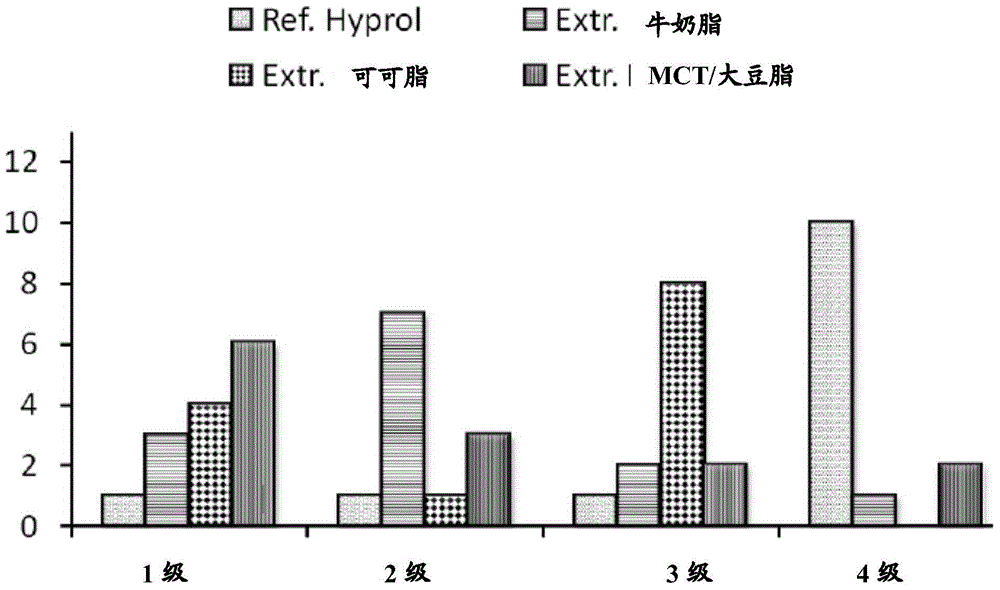

[0091] Samples were prepared with milk fat, cocoa butter or a mixture of medium chain triglycerides (MCT) and soy lecithin. The amount of each oil / fat added is 4%-10% Hyprol by weight TM 3315 solution, and then extracted. Thirteen trained members rated the samples from least bitter (level 1) to most bitter (level 4). Such as image 3 As shown, the cocoa butter samples were slightly less bitter than the control, and the hyd

Embodiment 3

[0093] In order to further test the encapsulation of bitter peptides in solid lipid nanoparticles, Hyprol TMFat coating of 3315 was performed using fluidized bed coating (Glatt, laboratory scale). Obtained solid lipid nanoparticles such as Figure 4 shown. After fat coating is completed, 10% Hyprol TM The reconstituted solution of 3315 was no longer bitter, which means that the hydrophobic bitter peptide was encapsulated in the solid lipid nanoparticles and was not released in water.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap